We got a bat signal from a group of doctors who were having trouble with ill fitting restorations to tibases. This can suck up a lot of time and energy to pinpoint the exact source of the issue, and you basically have to go through a pilot’s checklist before take off. Here’s a list you can use for yourself to determine what the cause of the issue, after you understand what the issue really is.

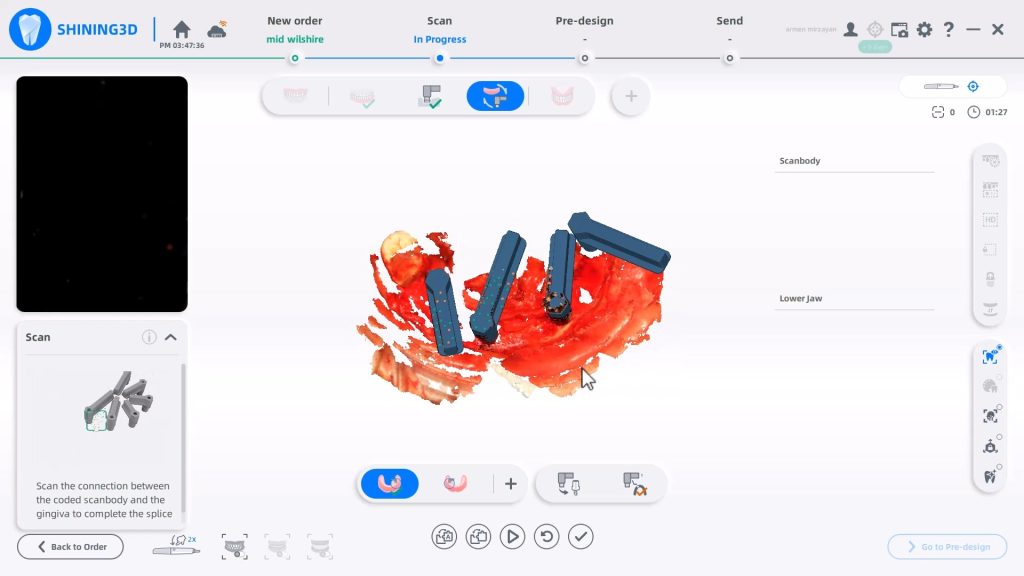

- Take a picture of the scanbody and a picture of the tibase and then pictures of their packaging material and verify you ordered the right parts

- Do not mix scanbody from company A to image implant fixture from company B and then mill a restoration to a tibase manufactured by company C even though they all say they are compatible with company D.

- Verify that you have the latest library of scanbodies

- Verify that you correctly chose the right scanbody from the large list of implant possibilities on the market

- Verify that you have the correct height as a lot of companies have the multiple height scanbodies for same diameter fixture

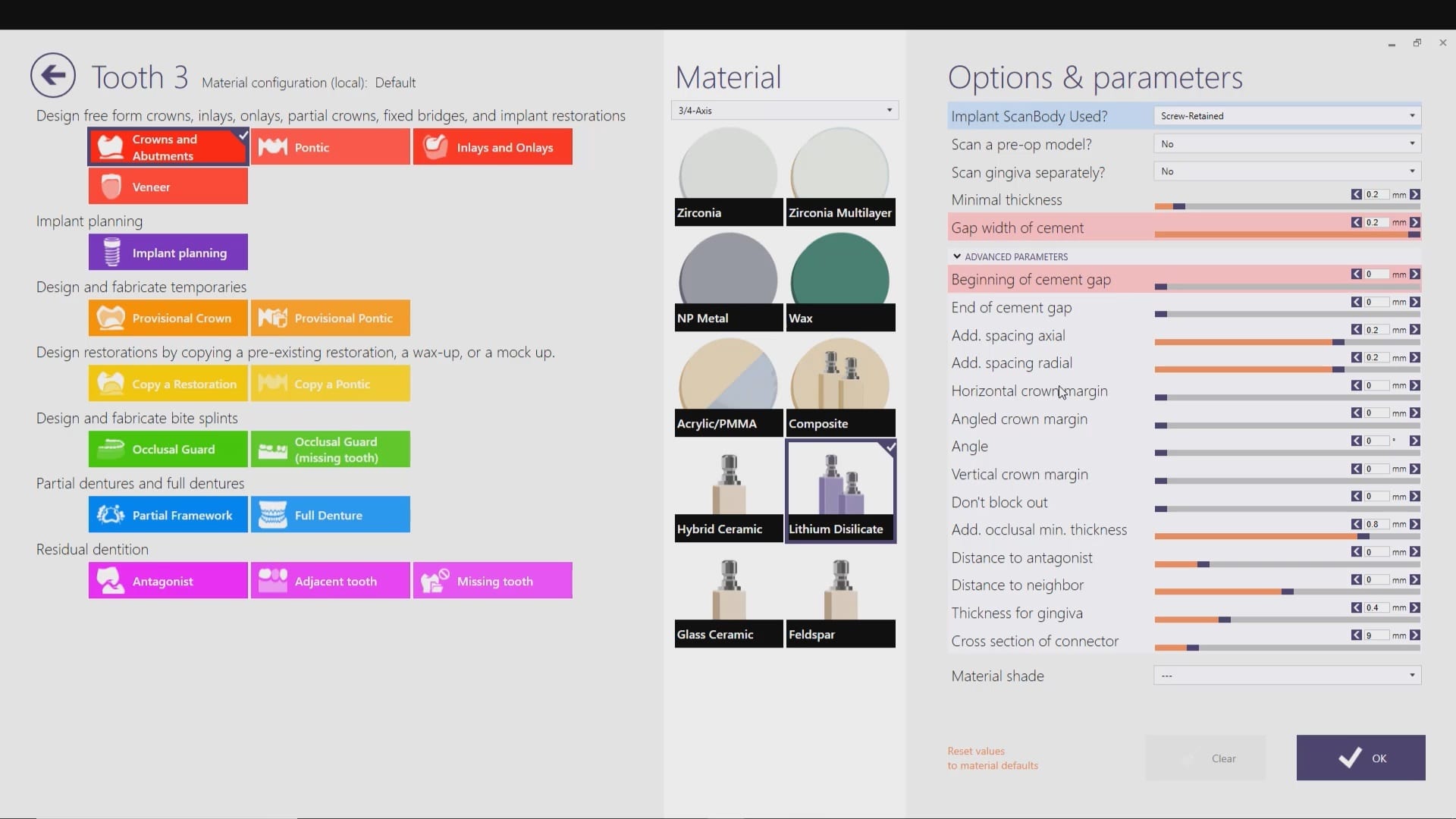

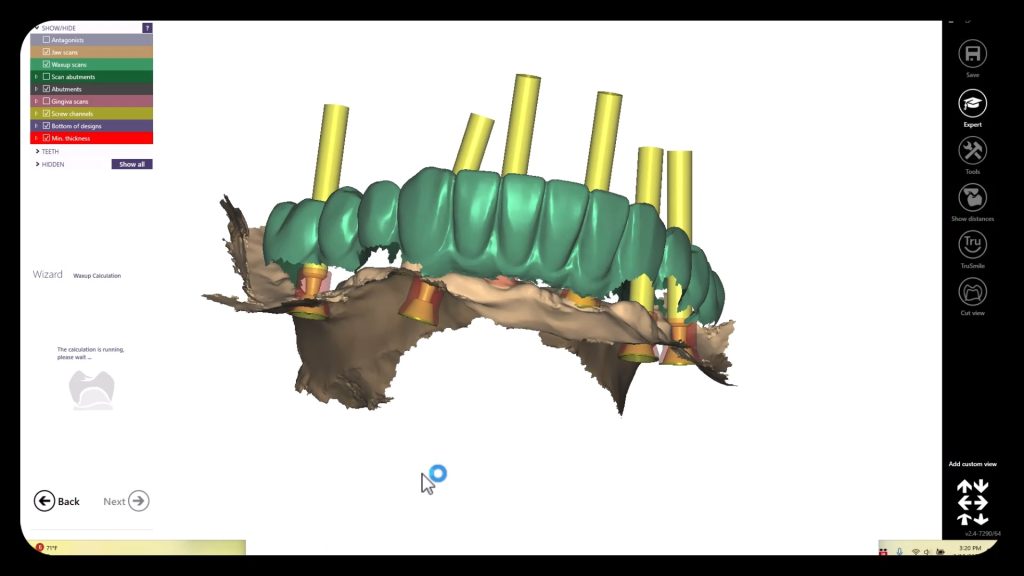

- When starting a case, you select either Custom Abutment for the implant restoration if there is no screw access hole and Screw Retained Abutment if you do have a screw access channel

- Understand that the decision for custom titanium abutment is made when you identify the scanbody in the design step, not in the job definition step

- You will not be able to verify seat / index until you fire and shrink material like zirconia

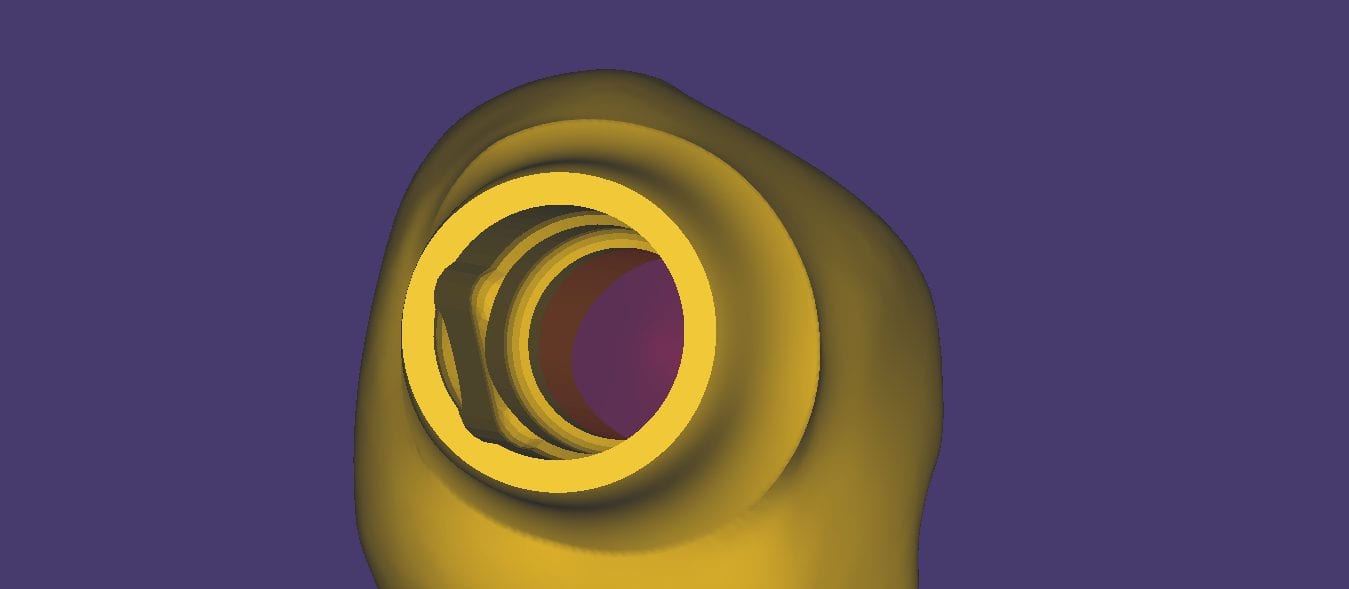

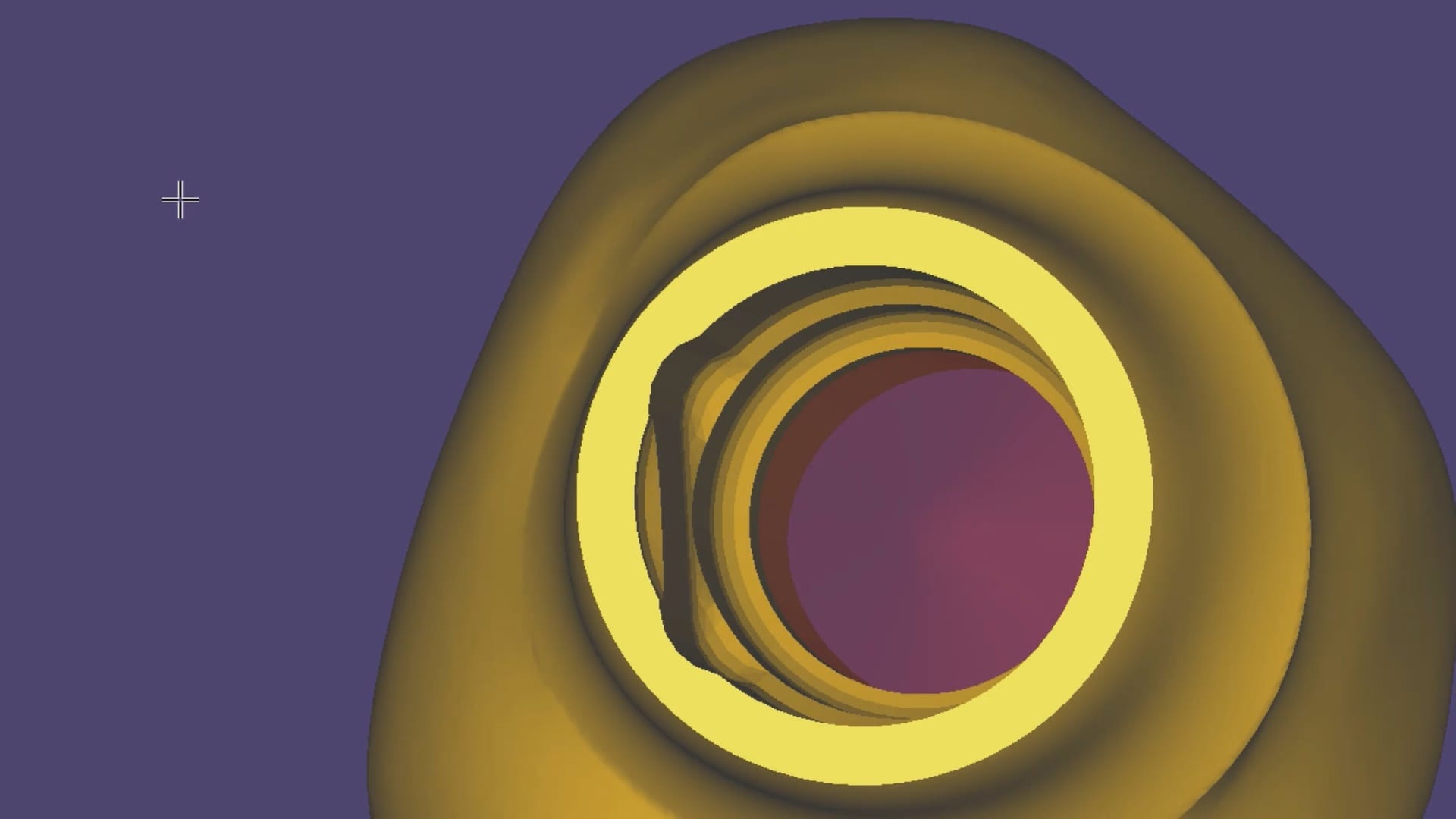

- The smallest drill in your milling machine will determine if you can carve out that much detail

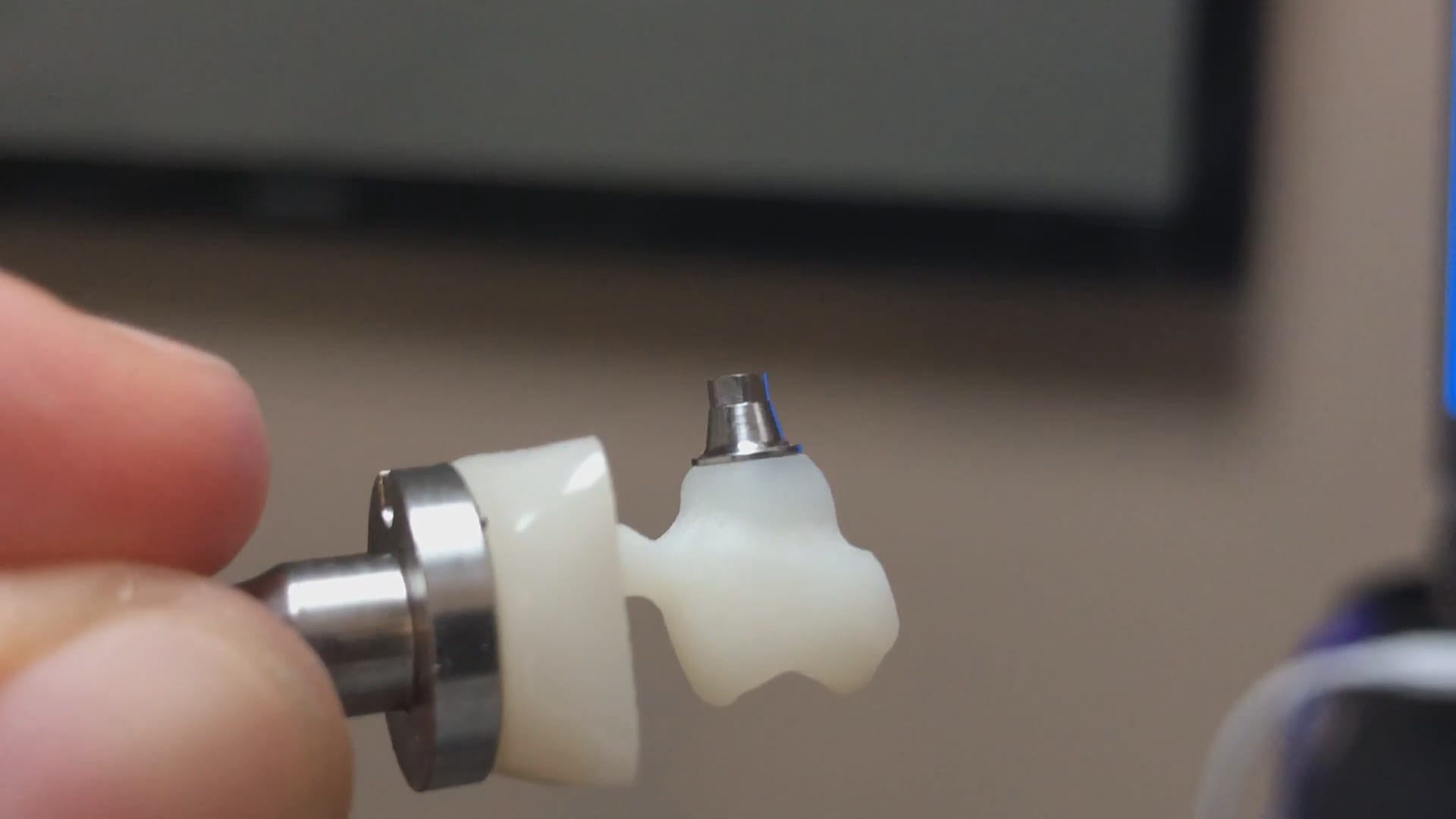

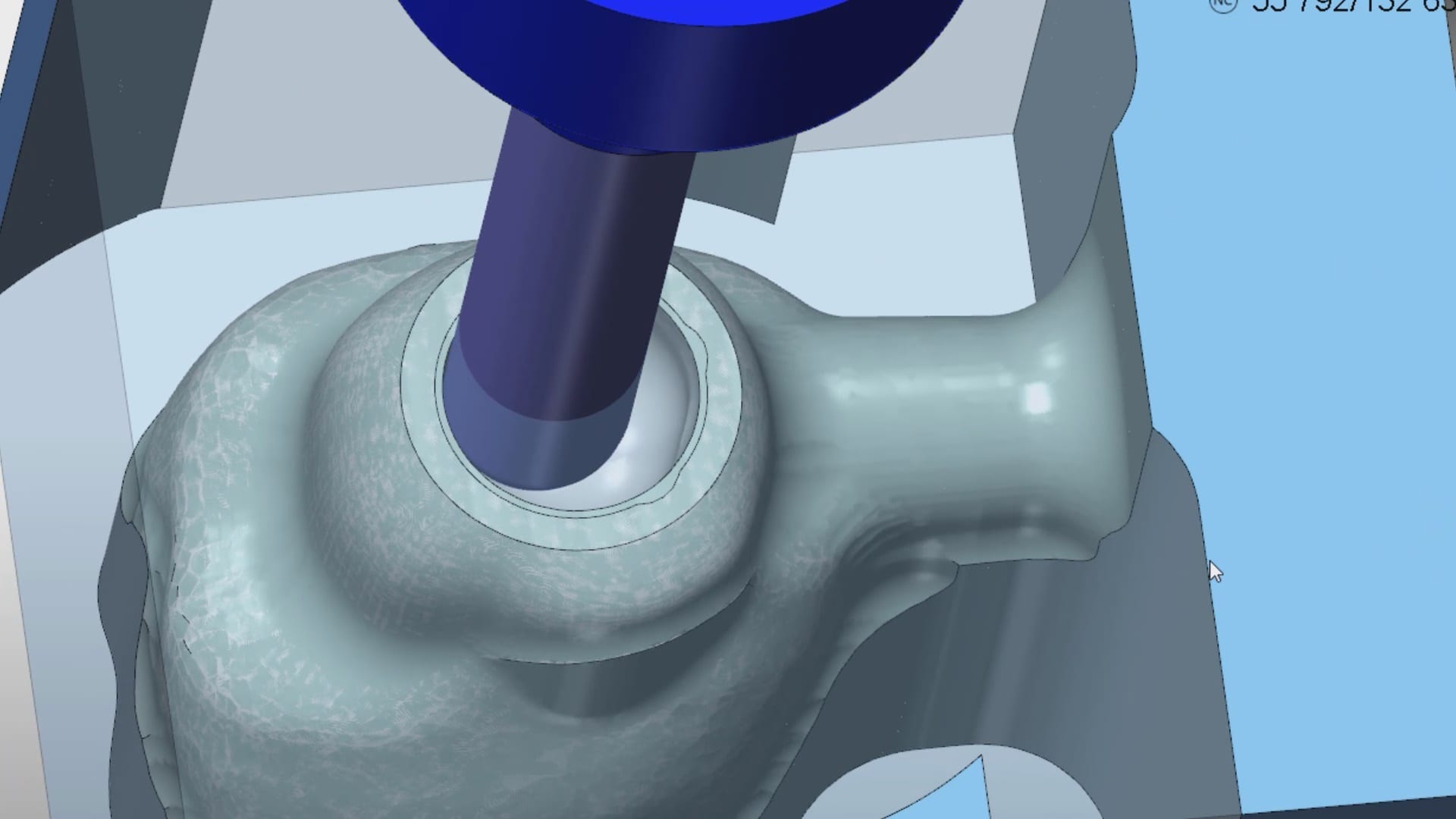

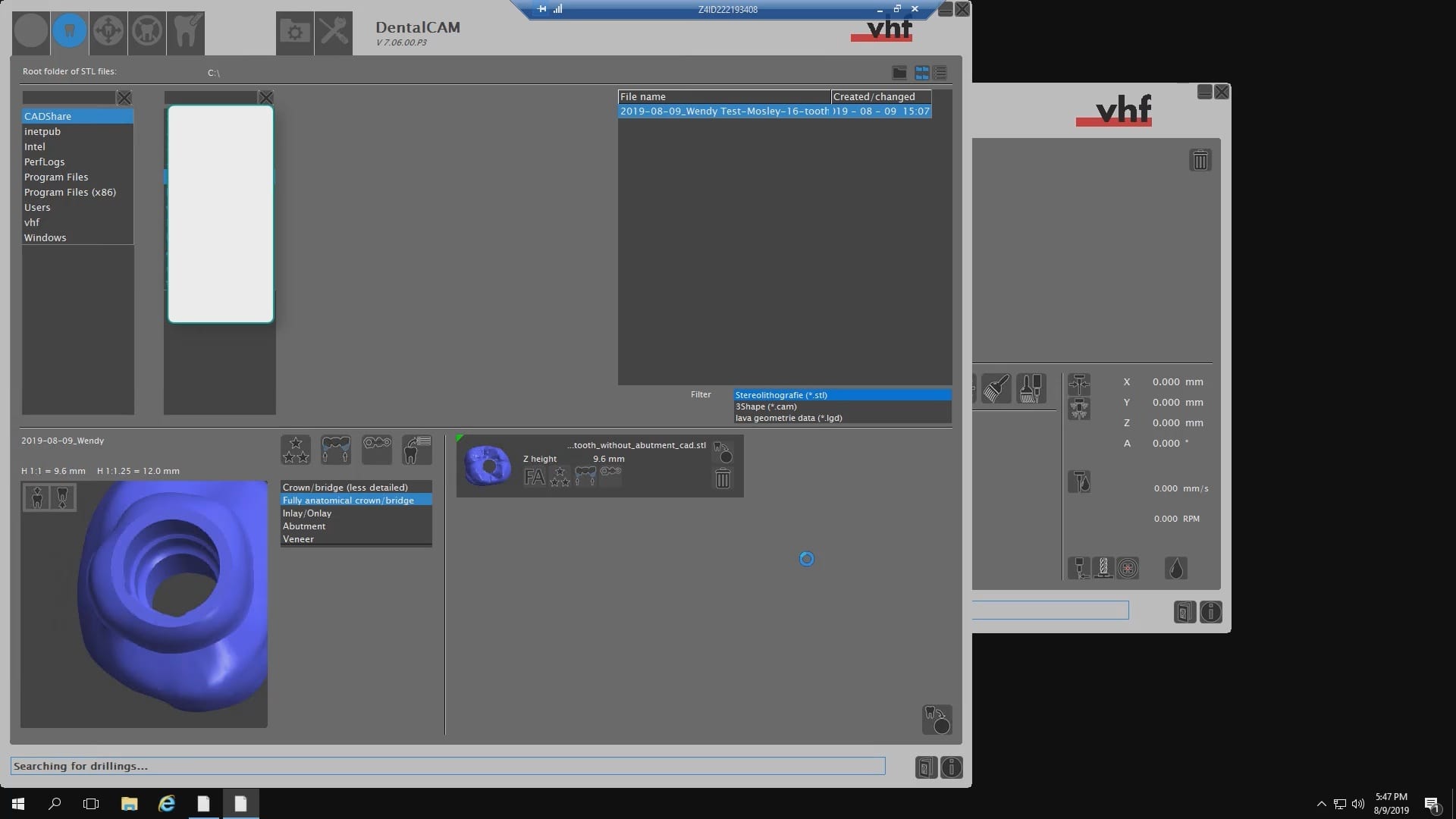

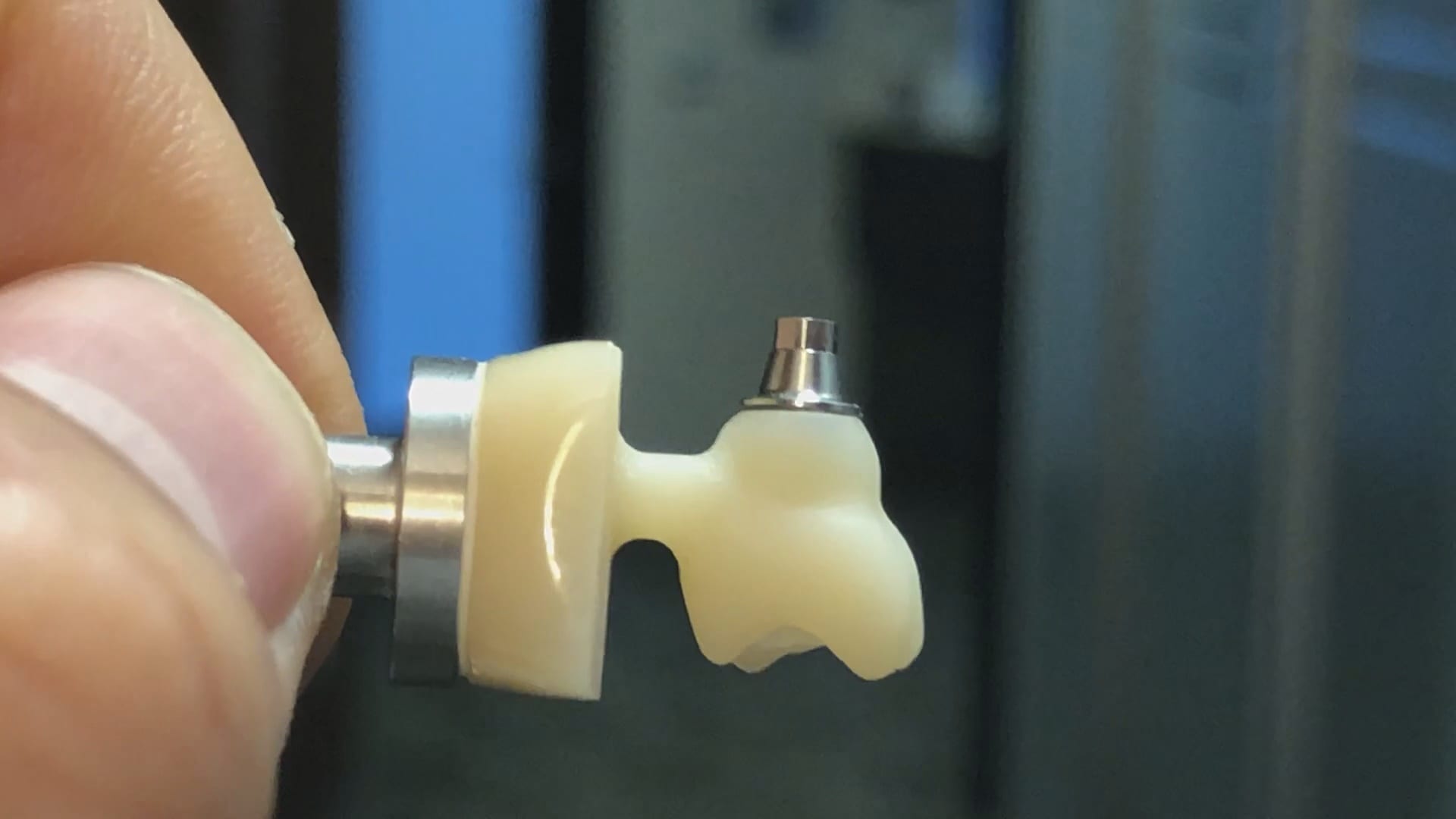

We took the case file from our users and directly imported their design case into a few of the CAM systems we have at CAD-Ray. We used Celtra Duo burner blocks to verify the fit. The screw-mentable restorations were binding on the walls of the tibase so it took a few adjustments to seat it completely. The good part is that the carbon on the titanium abutment leaves metal marks on the internal intaglio, so it is easy to know where to adjust

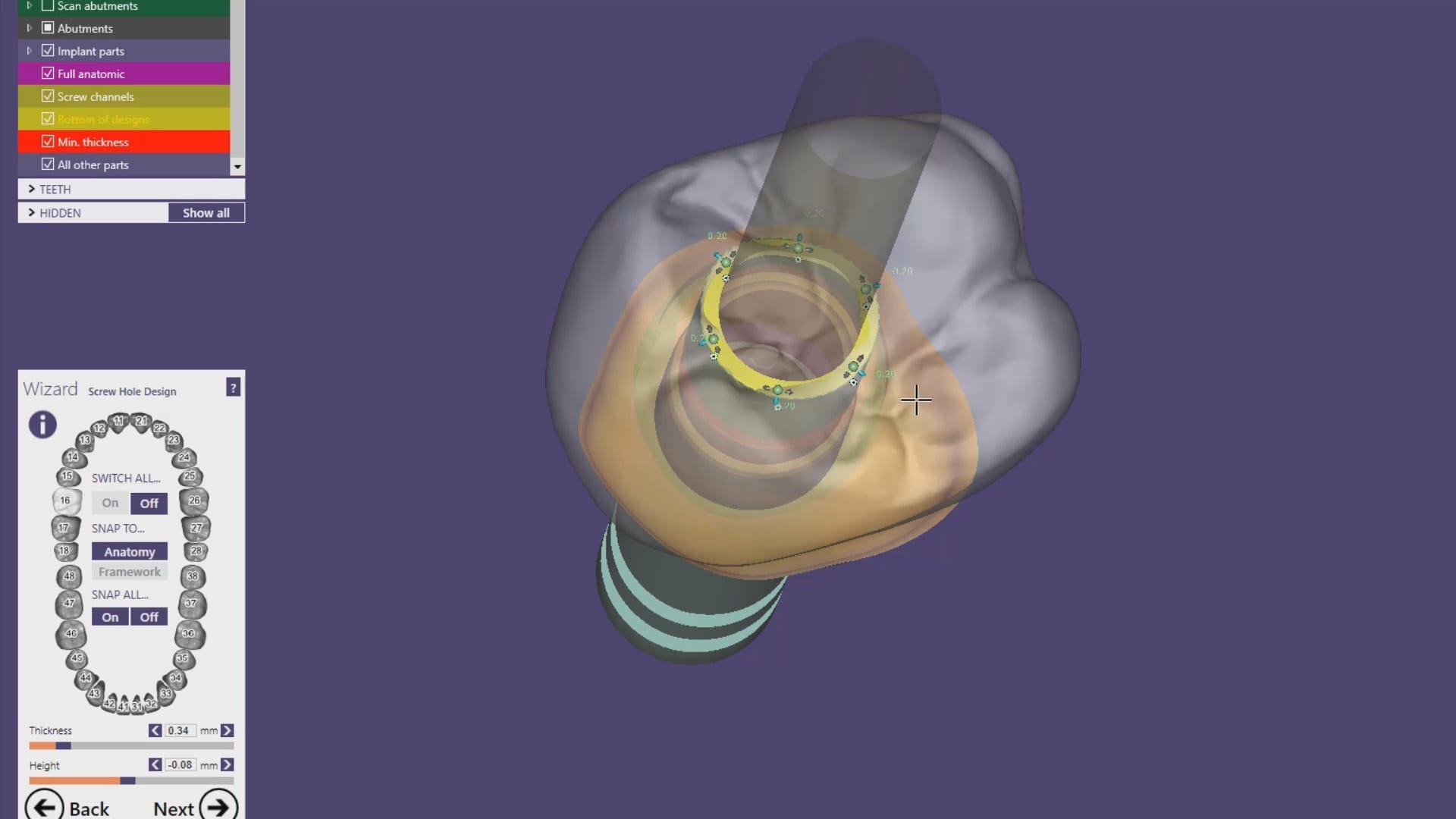

The restoration still needed some adjustments so we played around with some of the spacer settings, screw access holes, and other parameters to get it to seat all the way.

Even with these adjustments of the parameters a little analog milling helped get the restoration seated. The CAM software can give you plenty of hints on where it will bind. We recommend that you don’t change your spacer settings and understand that you will likely bind on the walls of the tibase and/or restorations as it is difficult for any machine to mill out all the detail you need to have NO adjustments. The good news is that the indexing and anti-rotation mechanism work properly.

In conclusion, it is physically impossible to mill the intaglio of a ceramic restoration to perfectly retrofit most tibases as they have too much detail that even 5 axis milling machines cannot reach. The choices are to increase the space between the walls of the tibase and the restoration providing enough relief to allow you to seat the restoration, but that comes at the risk of losing your antirotation mechanism. Alternatively you can mill them out knowing full well that they will bind and using the sophisticated CAM to pinpoint the areas that need adjustment.

You must log in to post a comment.