If you place enough implants, you may find yourself in need of a prosthetic part that just isn’t manufactured by anyone. For example, you may have a hybrid case on Bicons and for some reason you wanted to restored them with Multi Unit Abutments (MUA) and photogrammetry, yet there are no parts manufactured for such an endeavor. The problem is complex because a manufacturer needs to mass produce these parts and get them past regulatory matters.

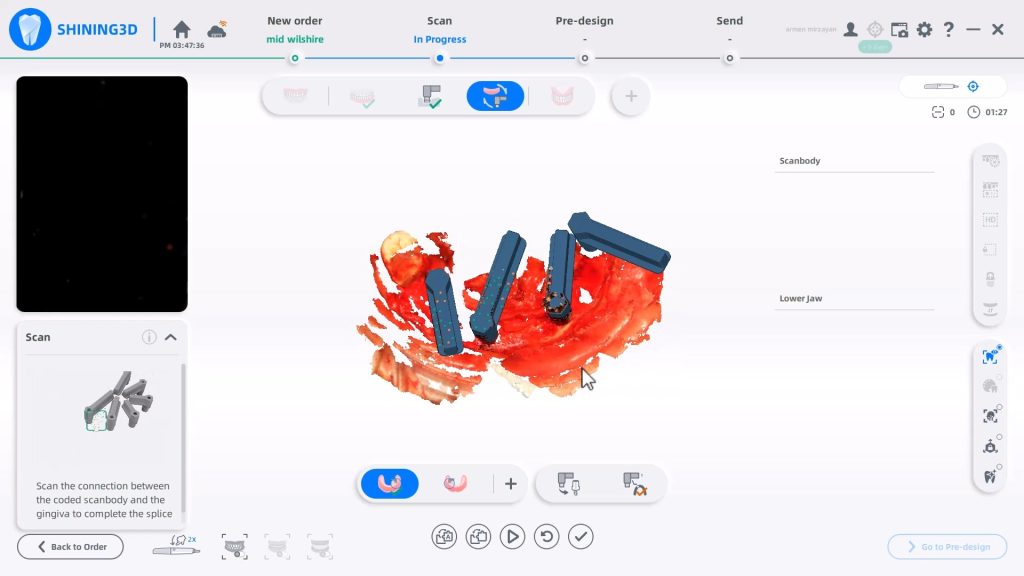

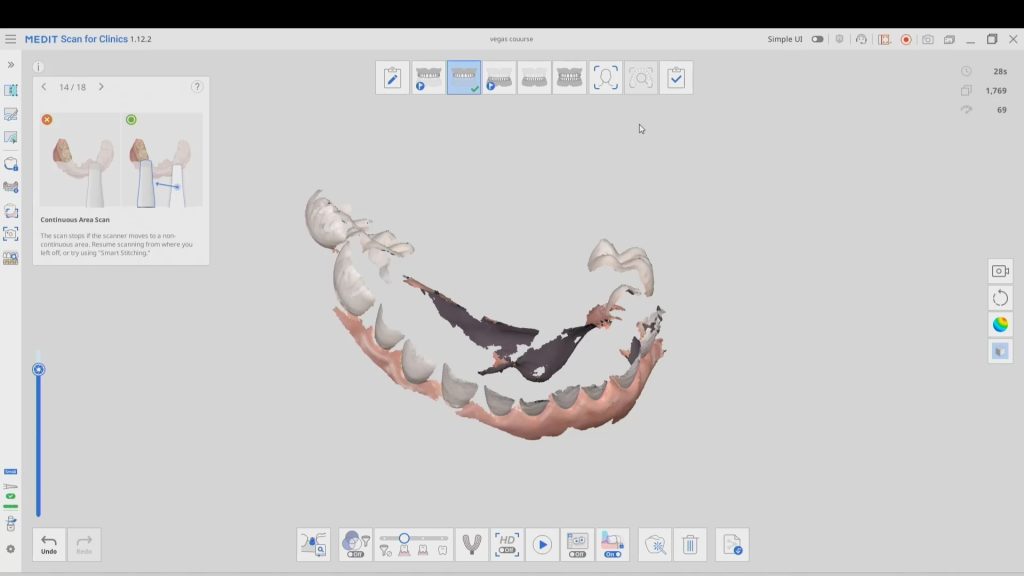

Some have found a simple solution, which is to have the parts custom made specifically for the implant. If they need the MUA part before the procedure, they just send a digital or physical model into a lab that can custom make the part. The lab itself needs a prescription form on the lab analog. Since it is custom made, you have direct input on how tall you want the height of the margin, how much you want to displace the tissue, how much would want the restorative head angled, etc..

Some have found a simple solution, which is to have the parts custom made specifically for the implant. If they need the MUA part before the procedure, they just send a digital or physical model into a lab that can custom make the part. The lab itself needs a prescription form on the lab analog. Since it is custom made, you have direct input on how tall you want the height of the margin, how much you want to displace the tissue, how much would want the restorative head angled, etc..

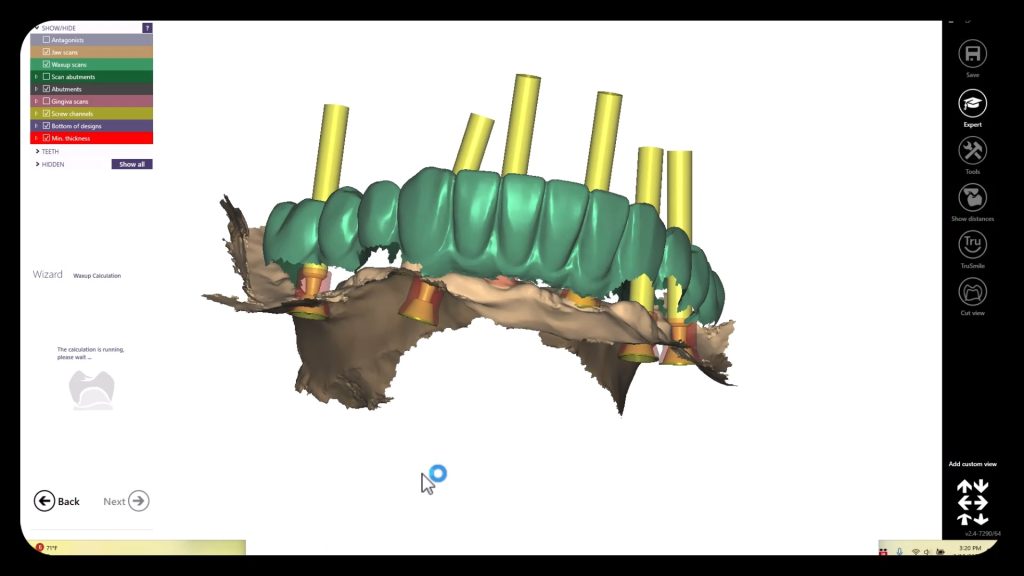

Most people will order a variety of them to address any situation on the same model and keep it in stock. What’s important to realize is that from the restorative standpoint, all your CAD software needs to know is the location of your abutment margins. It doesn’t care where fixture is and how the timing is lined up in the arch form. As long as it knows where the margins are, you can proceed with the design of the prosthesis.

Contact Andrew Seddler to send a digital or physical model and an Rx to get your custom made MUA’s

You must log in to post a comment.