The CAD-Ray team is happy to announce that CAD design software has experienced a breakthrough. One of the hurdles of using design software has always been that it was created with lab technicians in mind; the rationale being that technical staff would be using it more than clinicians. It is no wonder that many still send off their scans to labs to be designed “by the experts.”

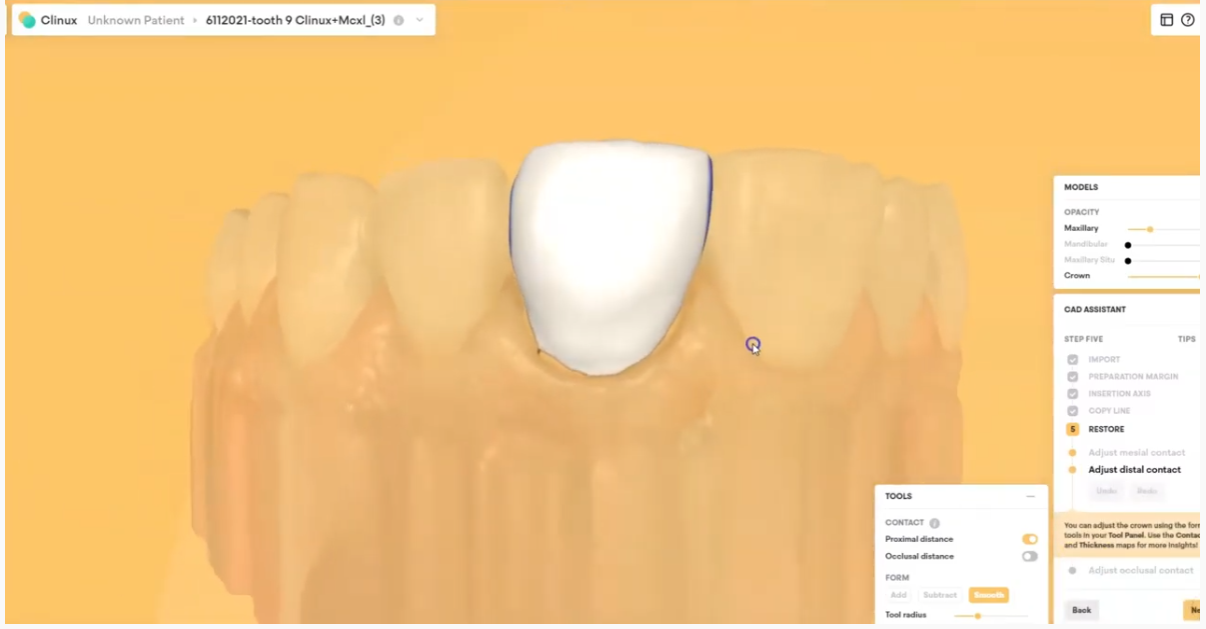

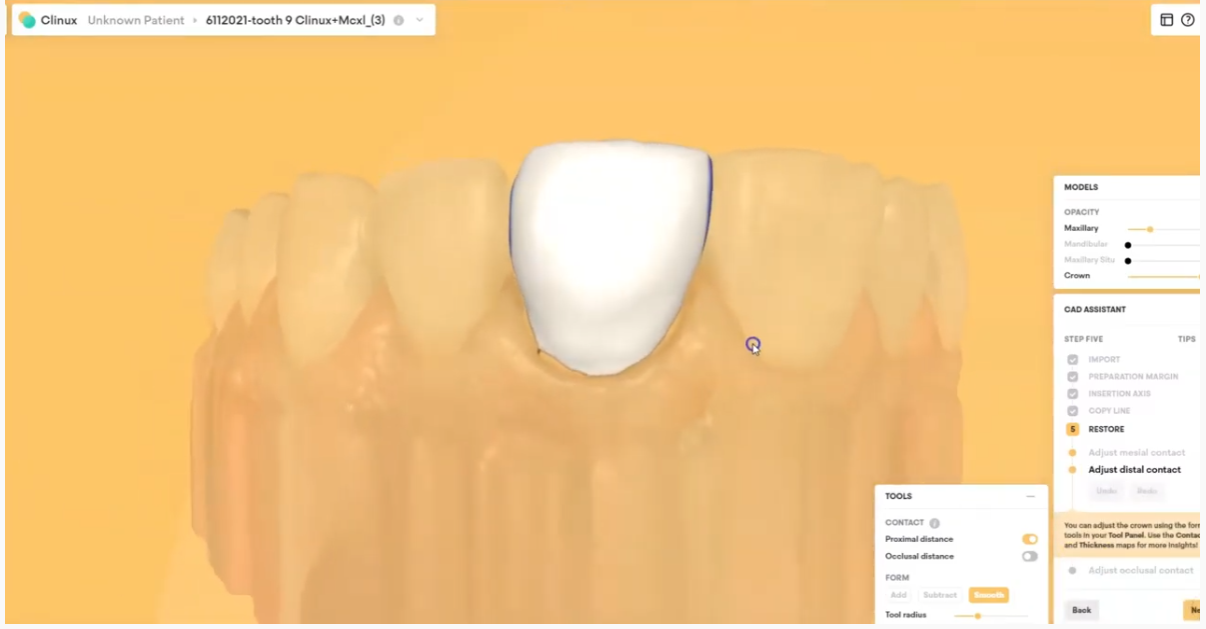

With the boom in digital and CAD/CAM dentistry, many offices are finally making the leap to bringing some or all of that workflow in-house to be done chairside (as they should). While there are many solutions available to incorporate one or more aspects of the digital dentistry workflow into your practice, it’s safe to say that the innovative design of Clinux is a turning point for design software.

Clinux is the result of collaboration by a team of experts from the most reputable and recognizable brands in the dental industry, all previously involved with advanced technology and equipment. It is made by those who have seen the pain points of the best programs in the dental world. They came up with a plan to eliminate the confusing barriers to simple plug and play design. Clinux is made for dentists in mind, not lab technicians. Less time spent onboarding, less clicks to your finished designs, and clear, reasonable fees all result in the first dentist-friendly CAD design software. Best of all, storage is not required. It is the first CAD design software that operates in the cloud.

Clinux; it’s completely independent, and curiously intuitive. It’s reasonably (and transparently) priced and very accommodating to workflow integration. Combined with the power of Medit, it is easily the most portable and efficient digital solution you’ll find anywhere. As always, the CAD-Ray team, the leader at post-sale technology support will be in your corner with its White Glove service. We encourage you to check it out and see for yourself…

We recently helped Medit launch its i700 Intra-Oral Scanner in Las Vegas. See the videos for demonstrations and interesting interviews

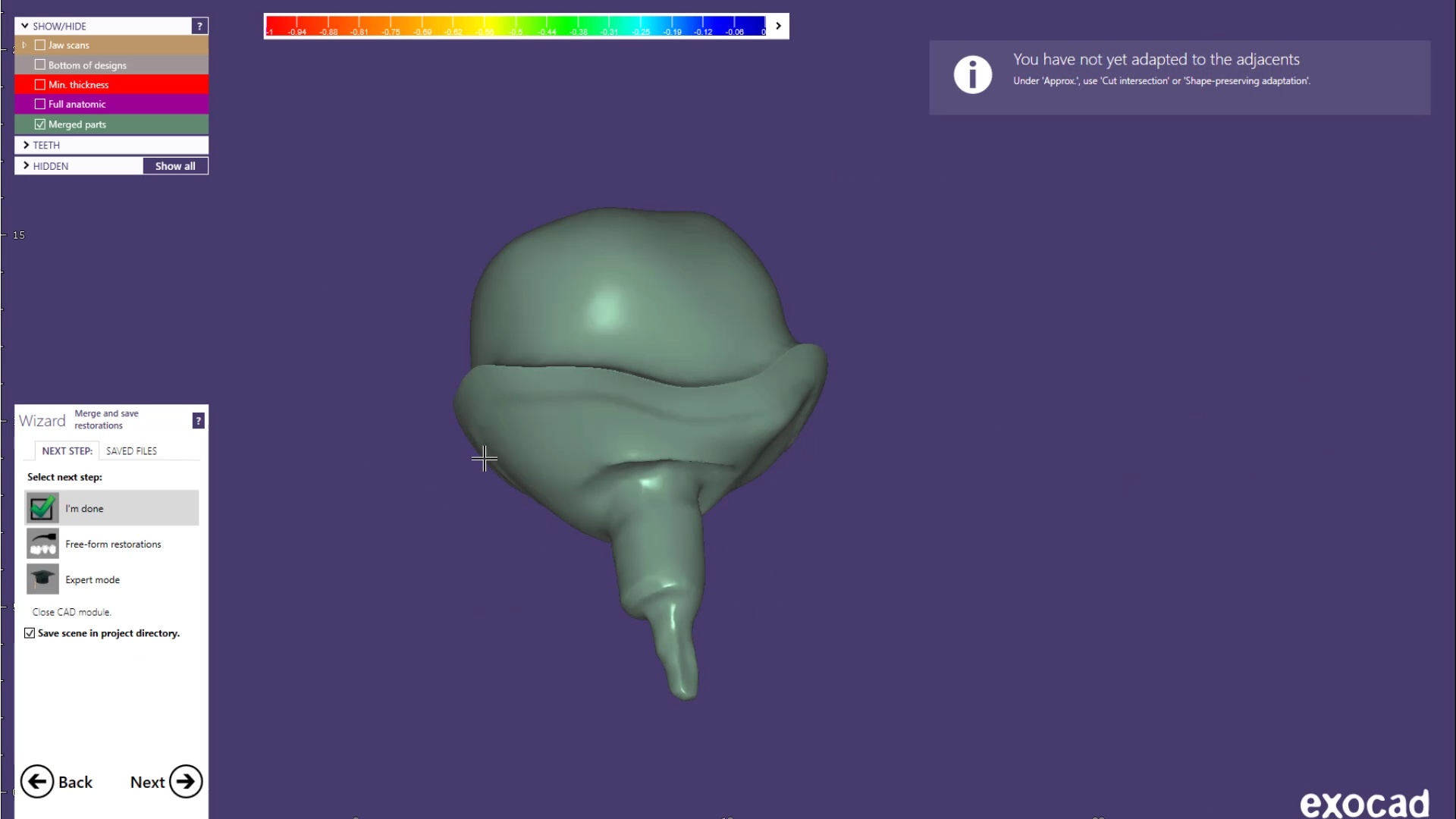

This implant was initially placed at the crest of the ridge in 2012. its placement did not allow proper emergence profile and subsequently lost bone around the head of the implant by 2015. The lack of blood flow to the crest of the bone at the cortical plate certainly could have contributed to its demise. By 2015, the bacteria trap forced a new restoration to be placed which also ultimately lead to chronic inflammation due to improper contours. The implant itself was well integrated and the decision was made to remove the top 3-5 mm of the implant and treat it as a cast post and core.

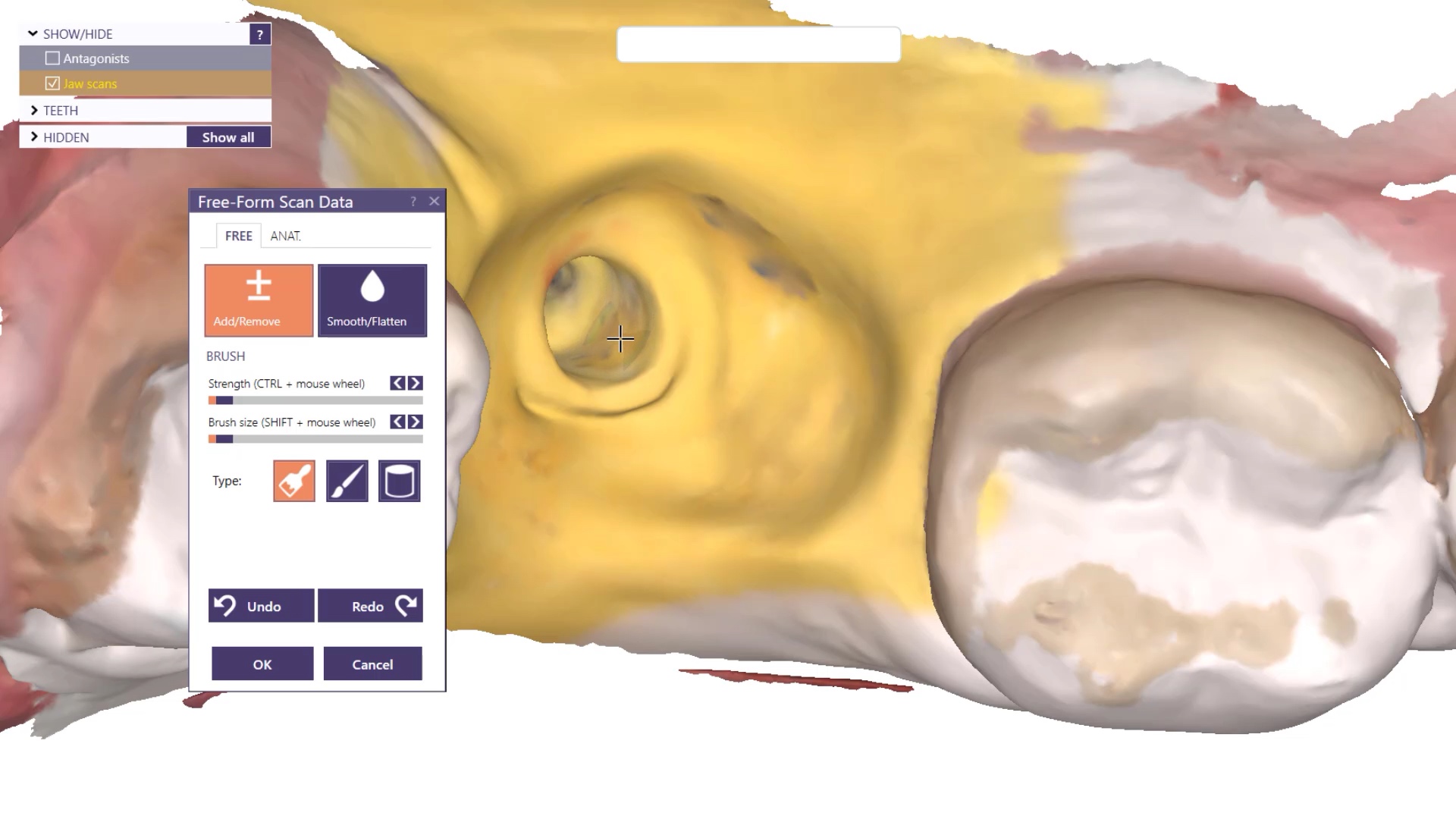

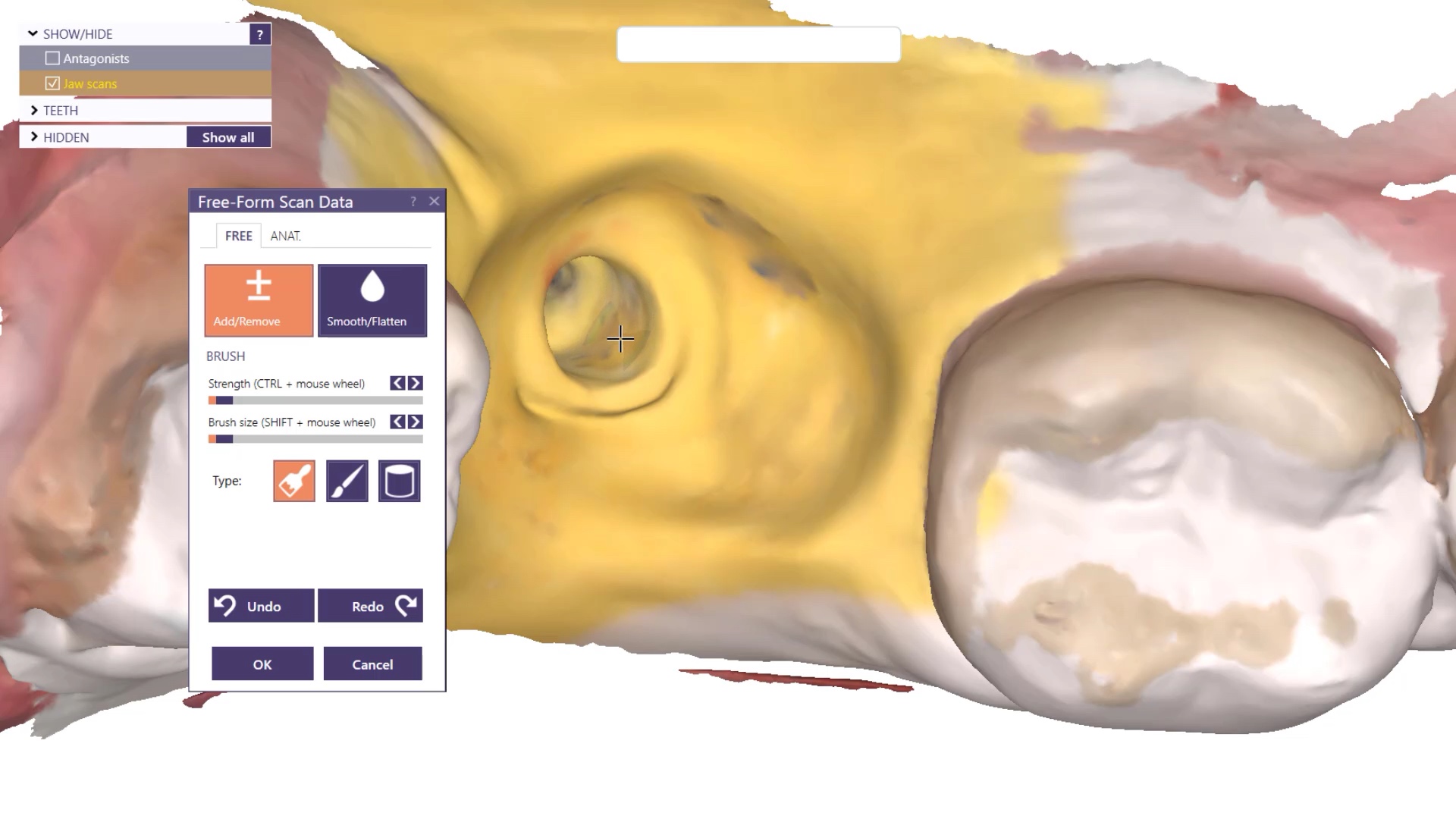

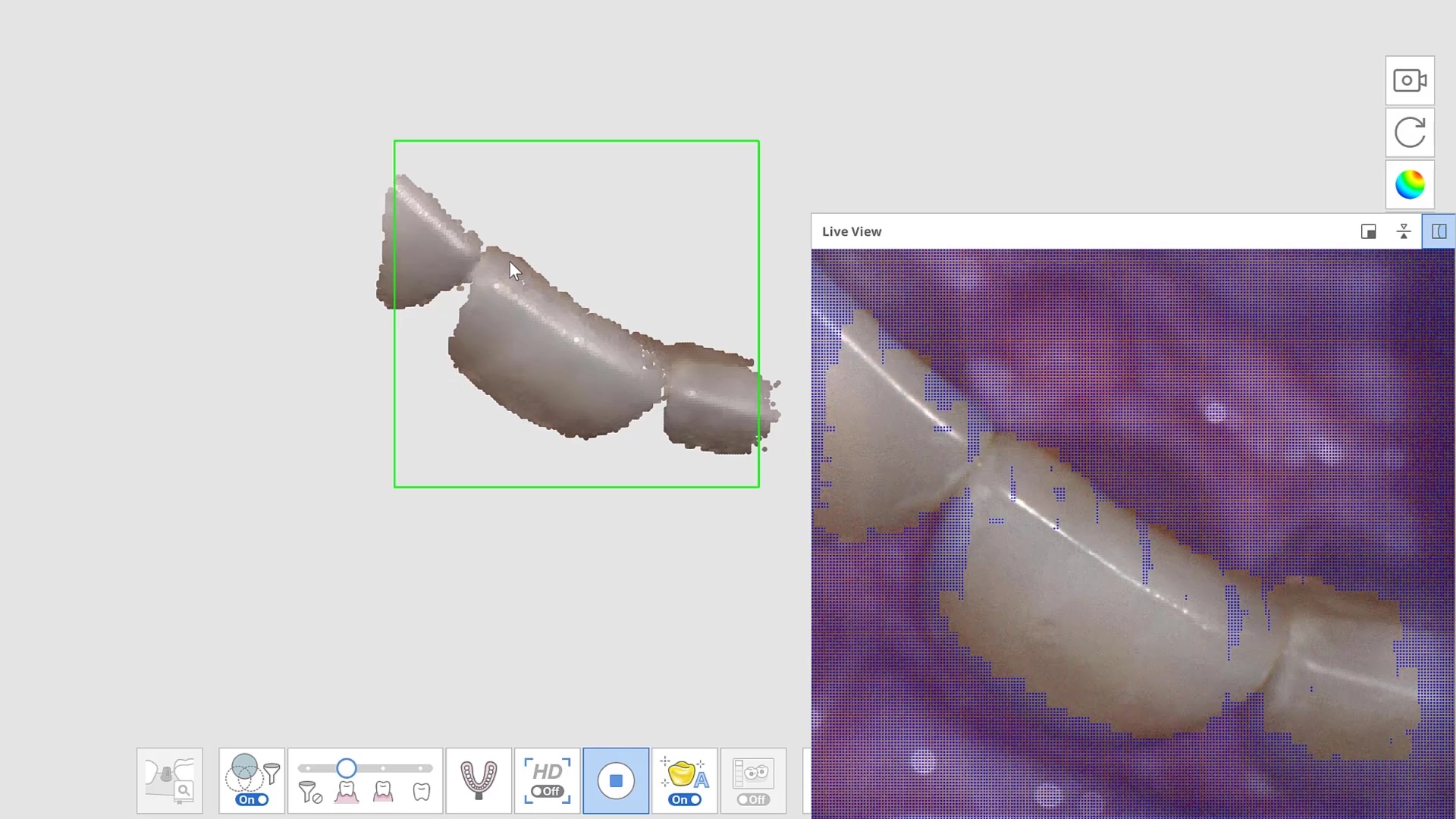

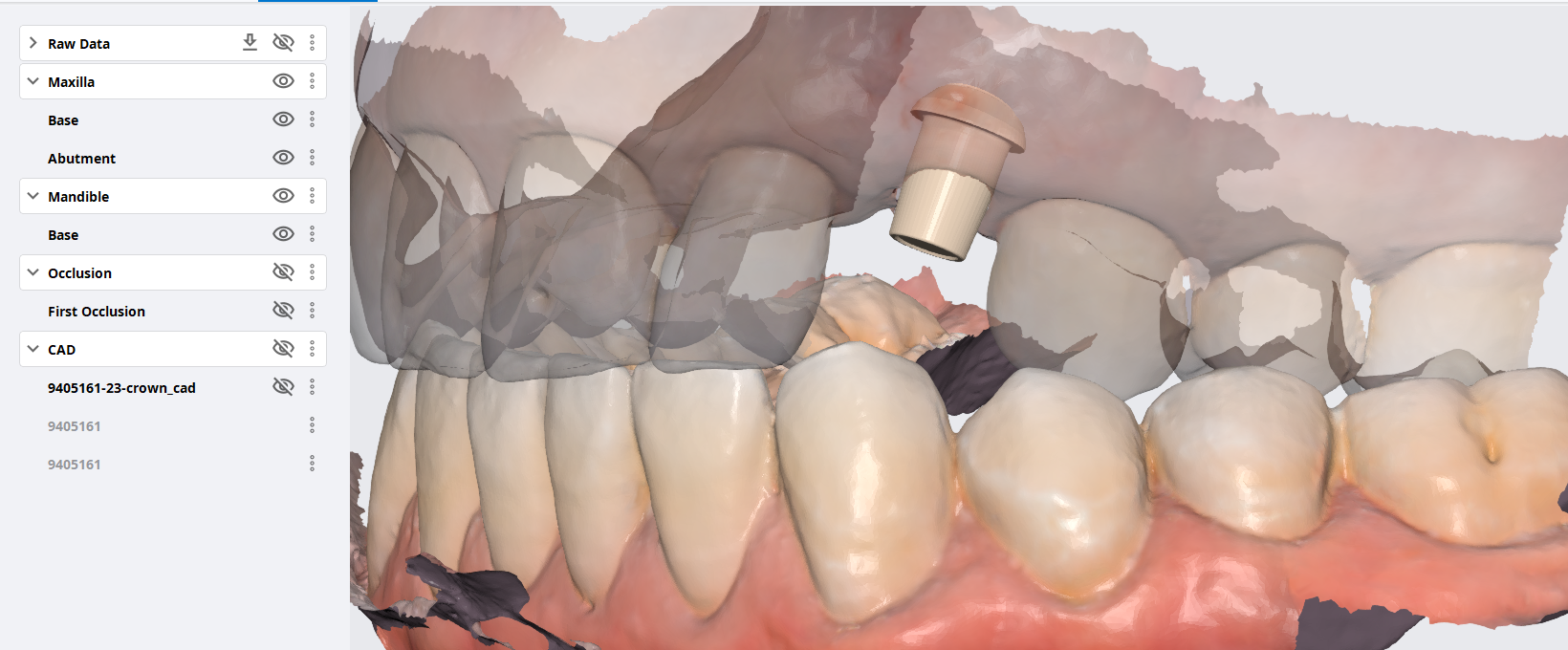

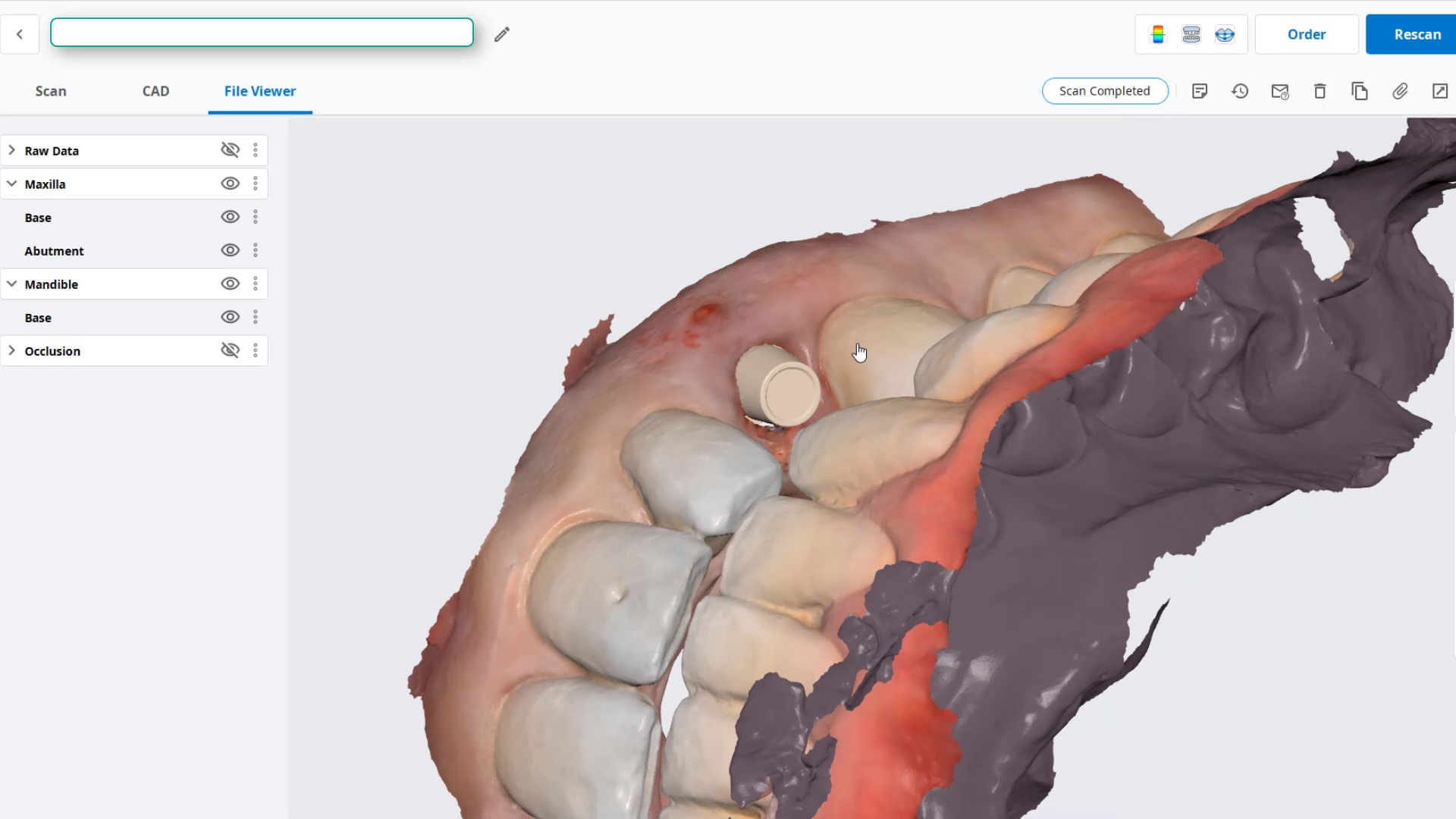

You can see how the Medit i700 was used to mix intra-oral scans with a PVS impression to capture the fixture. Advanced users can utilize the stl of the implant itself to fabricate a post and core digitally.

The designed restoration was then sent to Burbank Dental Lab and it was milled out of wax and then cast to metal

The post and core and the emax restoration were returned for delivery. The emax was not crystalized until after the abutment was cemented and then it was tried in by itself to assure proper contours and contacts. The great feature of lithium dissilicate is that you can add contact and glaze at the same time, which was required here as the mesial contact was weaker than desired after some minor adjustments

Post op x-rays to verify seat and no excess resin after flap was raised to clinically visualize that there is no excess cement

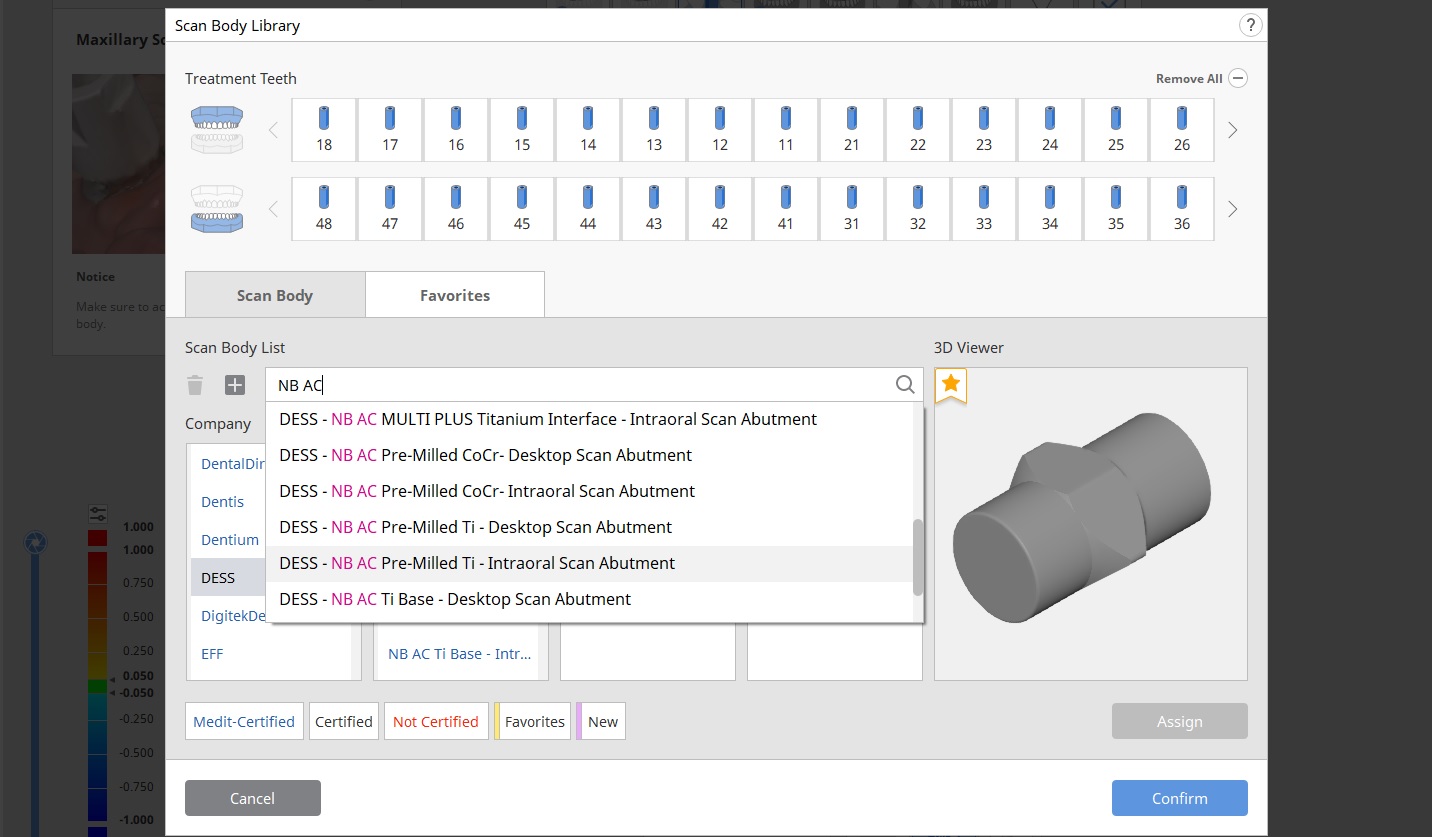

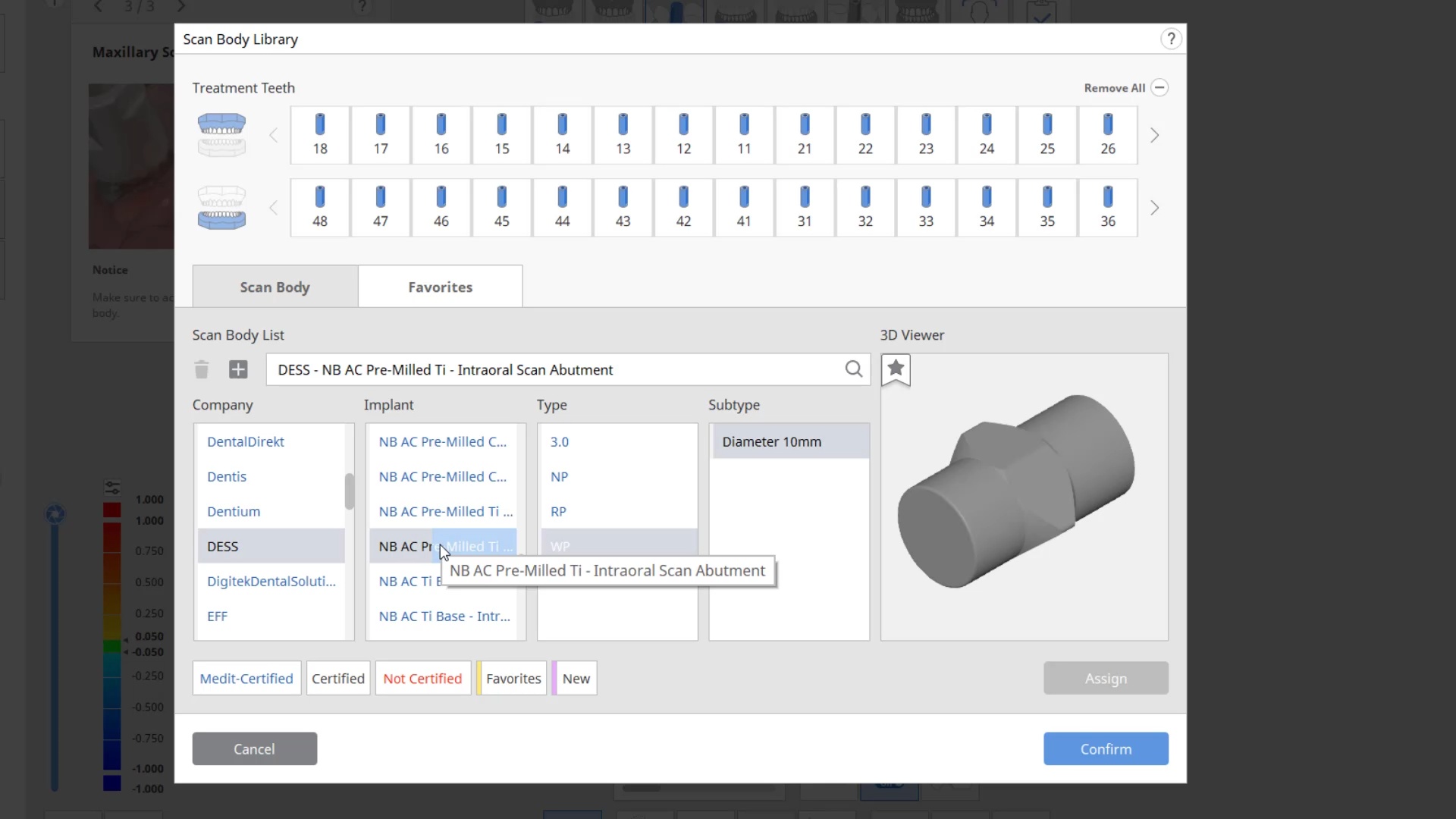

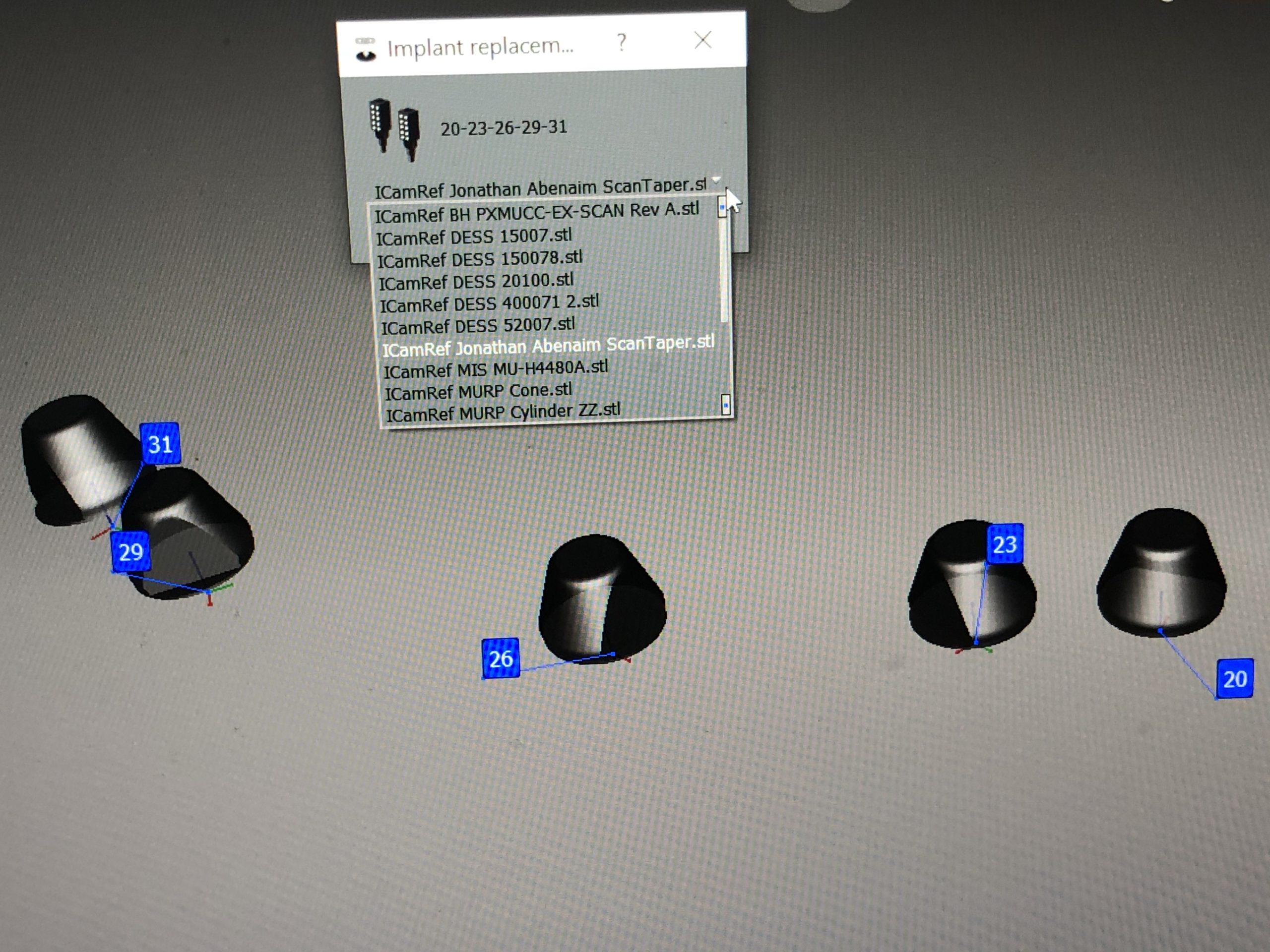

To use the Artificial Implant Suprastructure Identification Software to identify a scanbody, you have to understand how it is listed in the library. It is not listed by the name of the implant company but rather the manufacturer that fabricates that implant lines scanbody. For example, there are multiple choices for Nobel Active Conical Connection scanbodies. The easiest way to find them is to search for the pre-loaded brands, but be aware of the routing abbreviations many companies utilize. For Nobel Active, usually NB AC is used.

Then you must choose whether you are going to fabricate a Ti-Base or a Custom Abutment, and whether you are using an intra-oral or extra oral scanbody. The connection type (diameter) and the material (titanium vs. chrome cobalt) also must be selected. Here’s a quick video that illustrates the selection process. You must also consider if a 10 or 14 mm diameter blank is going to be used to mill the product. In molar areas, a size 14 is preferred so that you can reach the outer most boundaries of your desired margins, whereas a 10 mm blank may be too narrow and small for a molar.

For more detailed videos visit the Implantology Section of our Online Tutorials

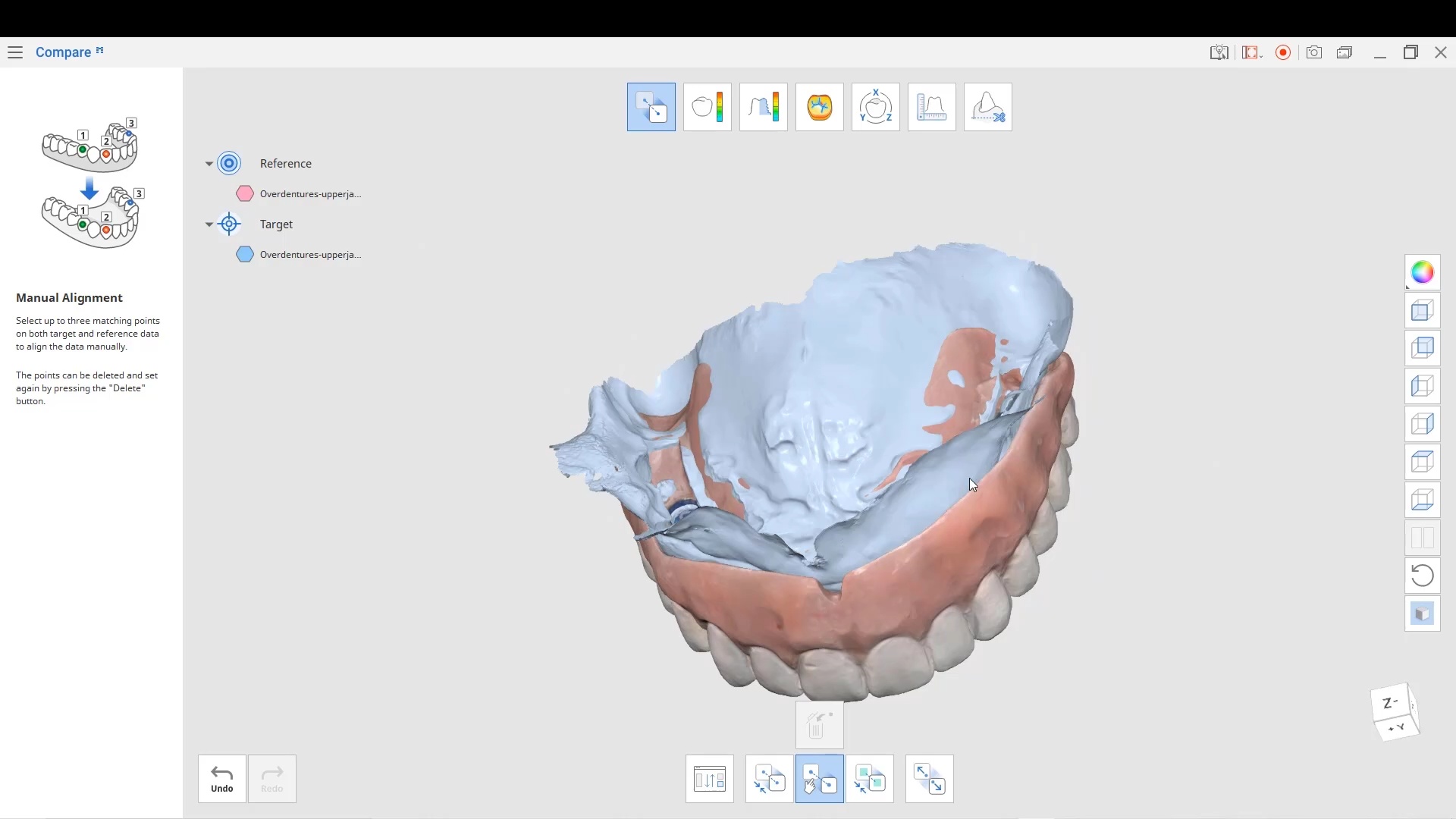

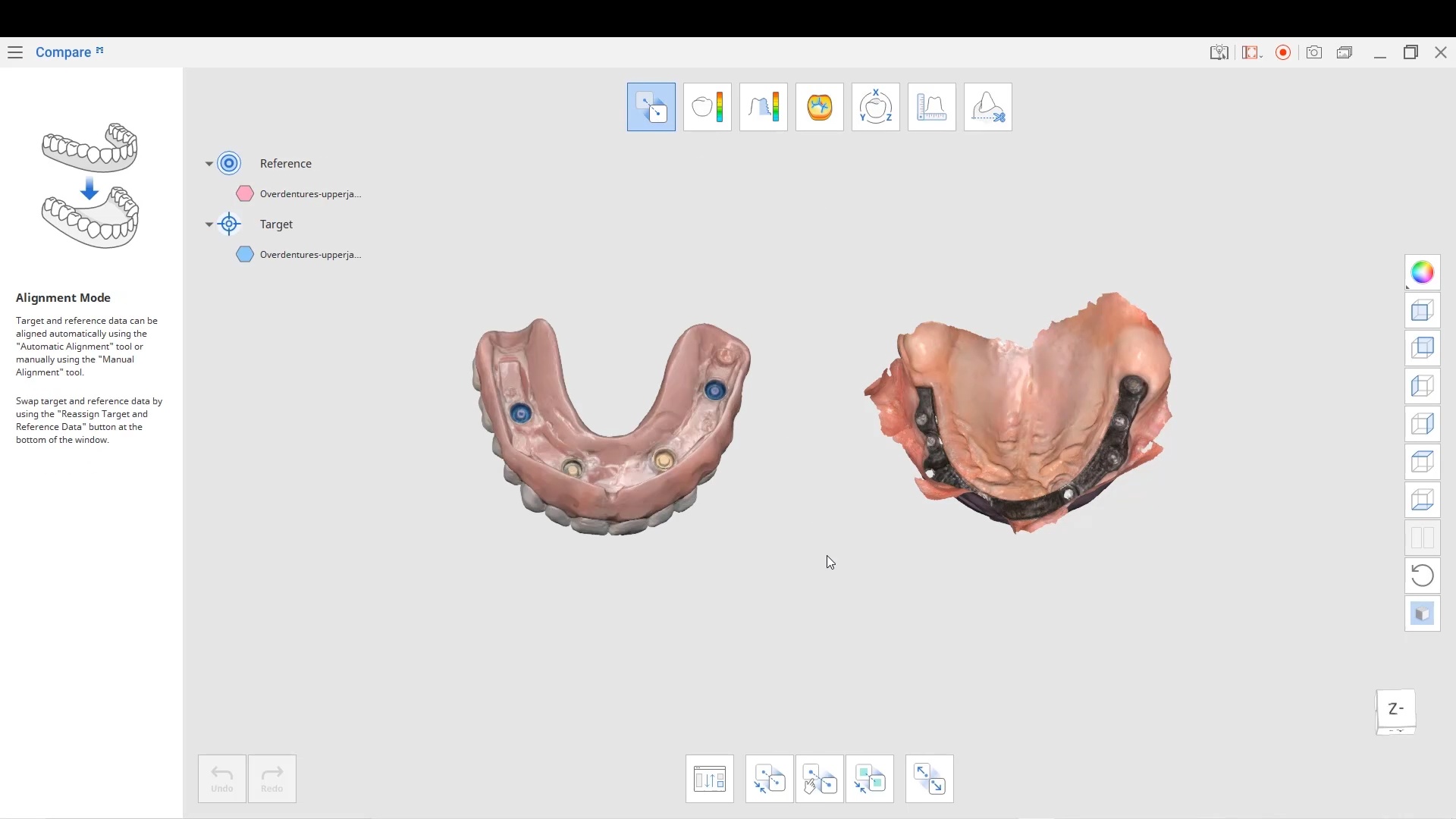

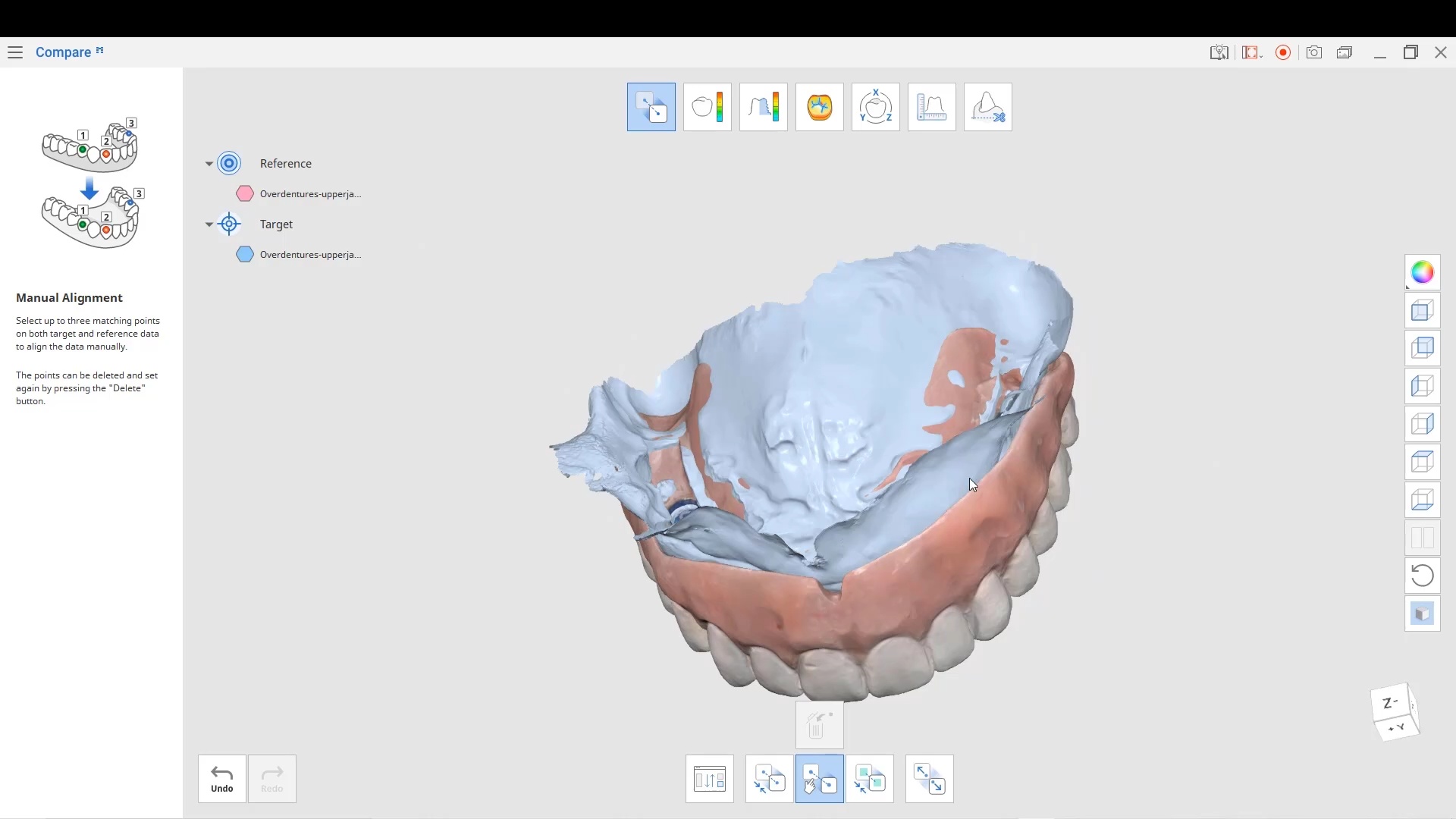

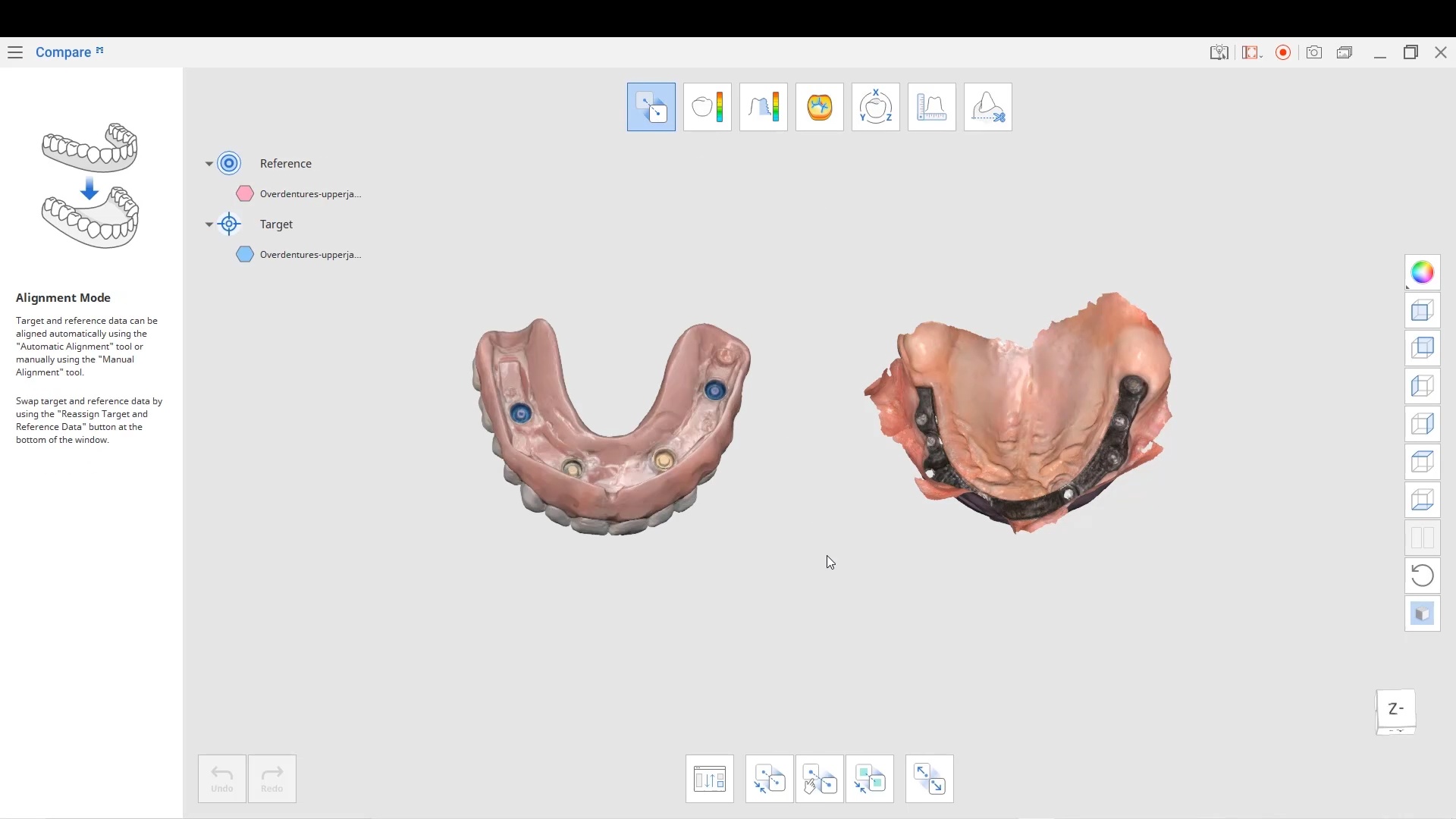

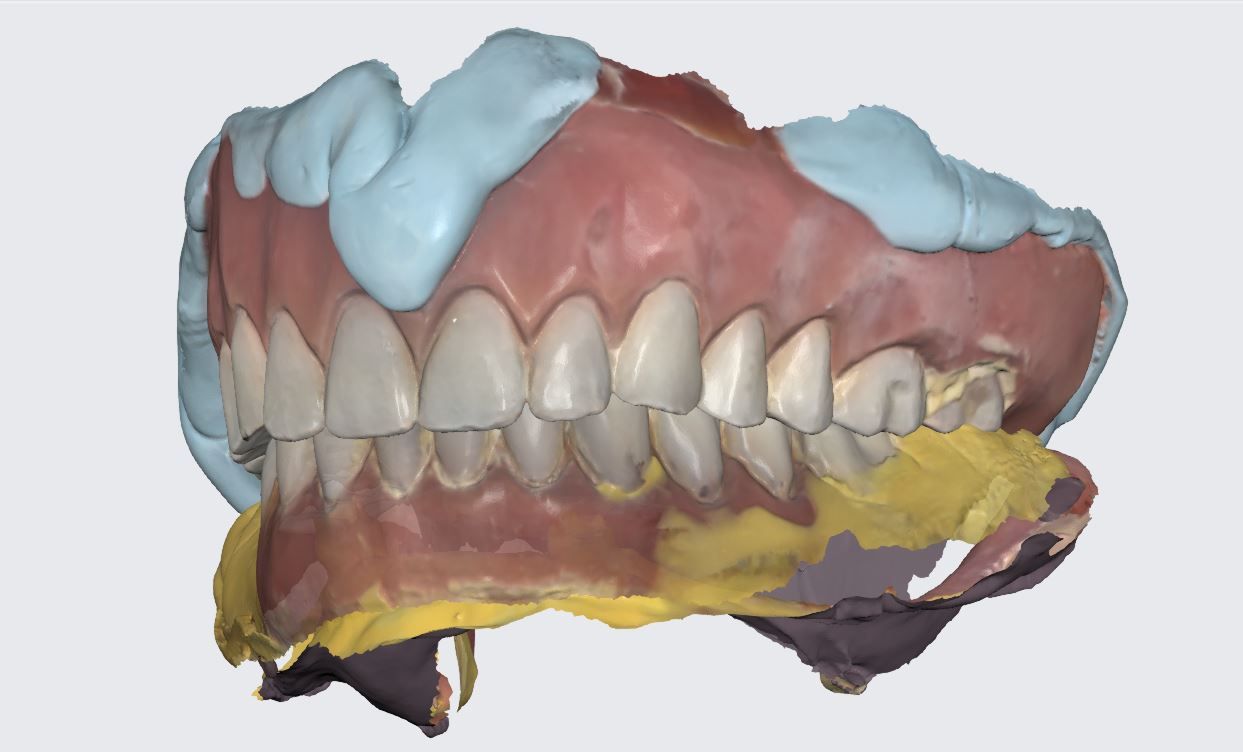

A fracture and worn overdenture greater than 10 years old was duplicated digitally where the lab was able to follow the vertical dimension and tooth position from digital impressions taken by the Medit i500. Clinically, we advise that you place the housings before taking the impressions to accommodate enough space for the chairside reline. In this particular case, most of the reline and imaging was done extra-orally

There is a lot of focus nowadays on the connection between the screw and the MUA and top clinicians are recognizing this to be the most vulnerable part of full arch prosthetics.

An issue to consider the space between the green and the blue arrows on the following photo and how some have designed solutions around the small area that is prone to chirping or breakage during milling or printing

“The powerball screw by Dr Jonathan Abenaim is one of a kind. Finally a screw designed to skip the tibase with the material in mind. It is rounded to provide gentle forces that are transferred to the body of the screw instead of the weak threads where the the screw is the weakest. It has the ability to be used in Zirkonia and pmma with no tibase. Its angle can be corrected up to 20 degrees. With our proprietary biaxial screw head the screw head is robust and cannot be stripped.”

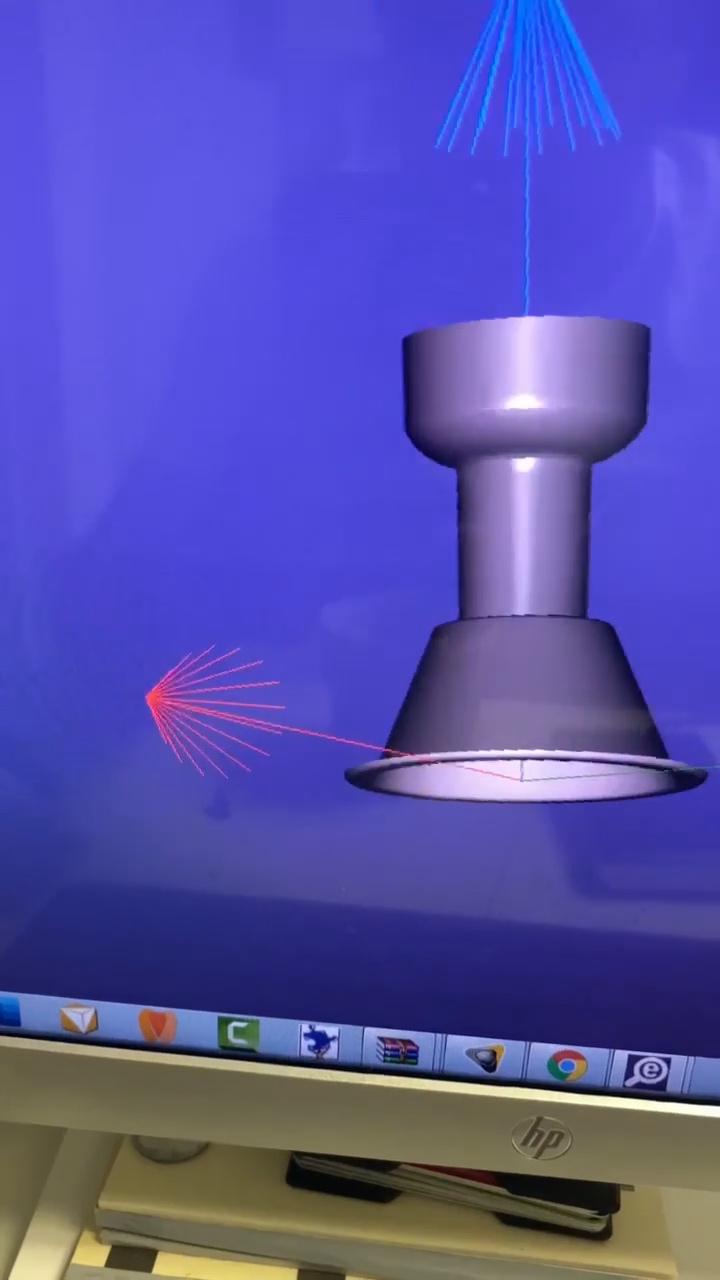

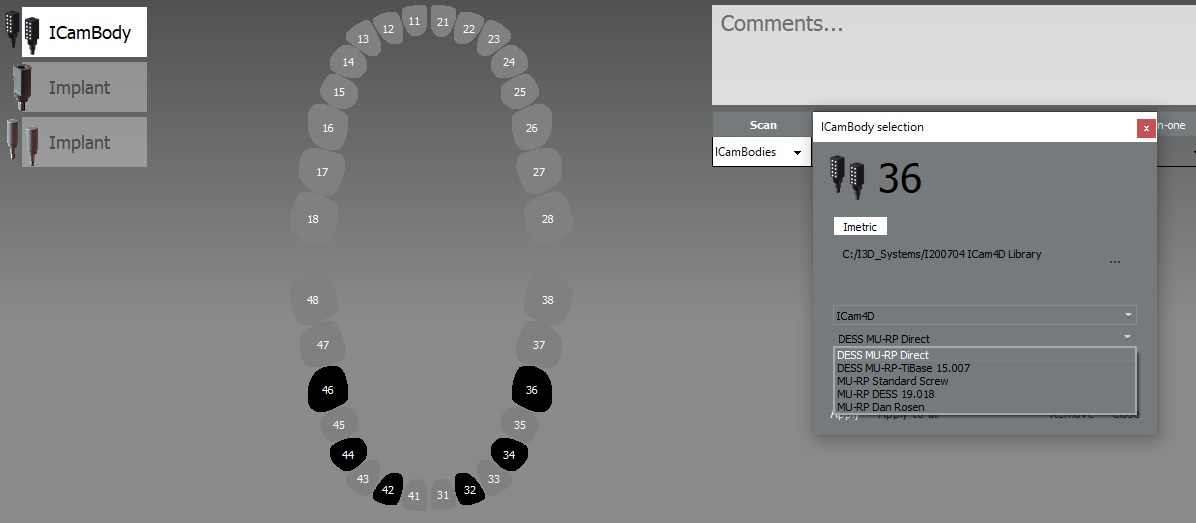

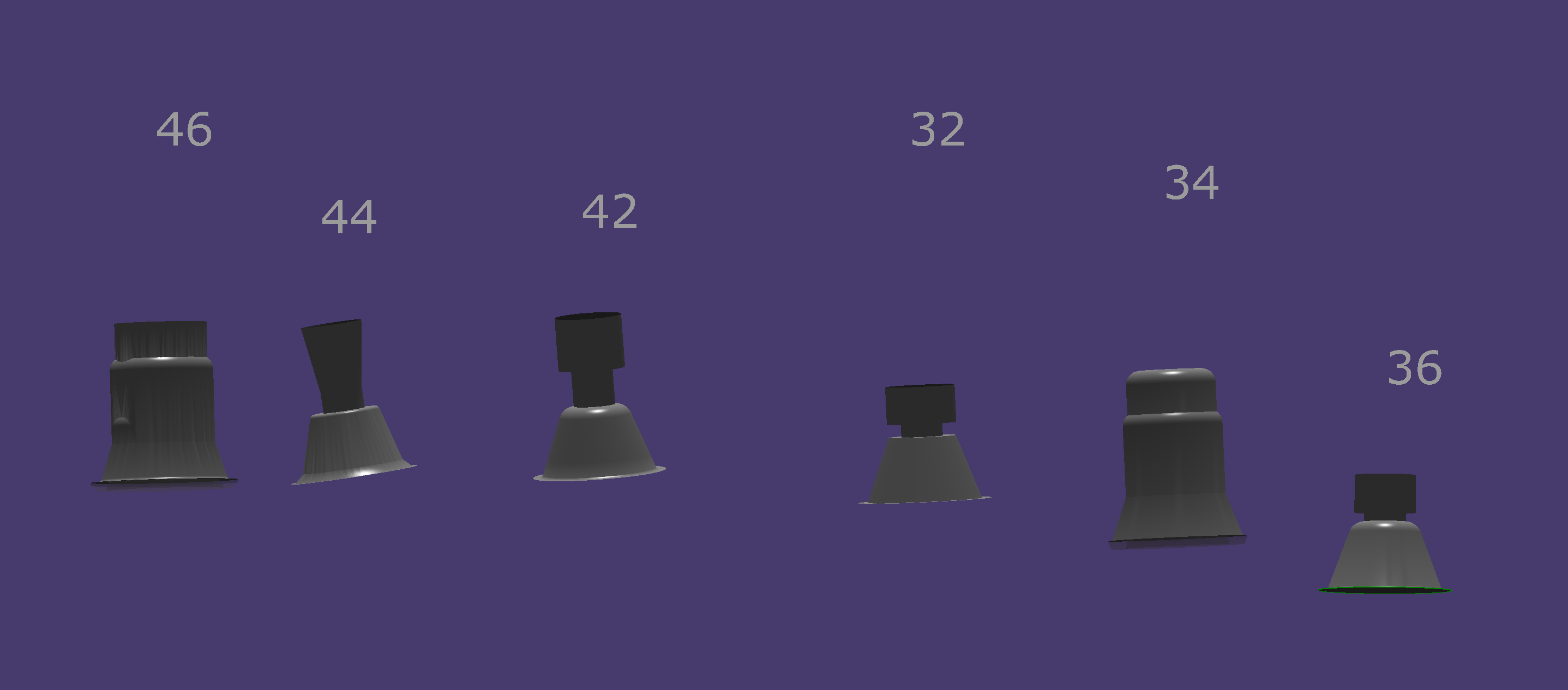

When setting up case in photogrammetry, you can select the type of screw you will be using for the prosthesis so that it gets incorporated into the design of the prosthesis. There is a trend developing where doctors prefer to mill or print directly to the Multi-Unit Abutment and a standard screw won’t suffice.

In Imetric’s ICam software you can chose which screw design you prefer which are often used to provide adequate spacing for the material and adequate length to engage the screw to the platform. Properly labeling the suprastructure at start up will provide the geometry you will need for the manufacturing.

We have an MO a DO on adjacent teeth that need to be done and a crown in between. It took only 90 minutes to do all 3. I prepped the crown and got that milling and while it was milling I restored the adjacent teeth. I then tried the crown in. what’s great about lithium disilicate vs zirconia chairside is that I can easily add a contact on with powder while its crystalizing. or I can adjust the composites to nail the contacts. so we leverage mill time and oven time with prep time. Said another way, it takes me the exact same amount of time to do a crown + 2 class two’s as it does to do a single crown

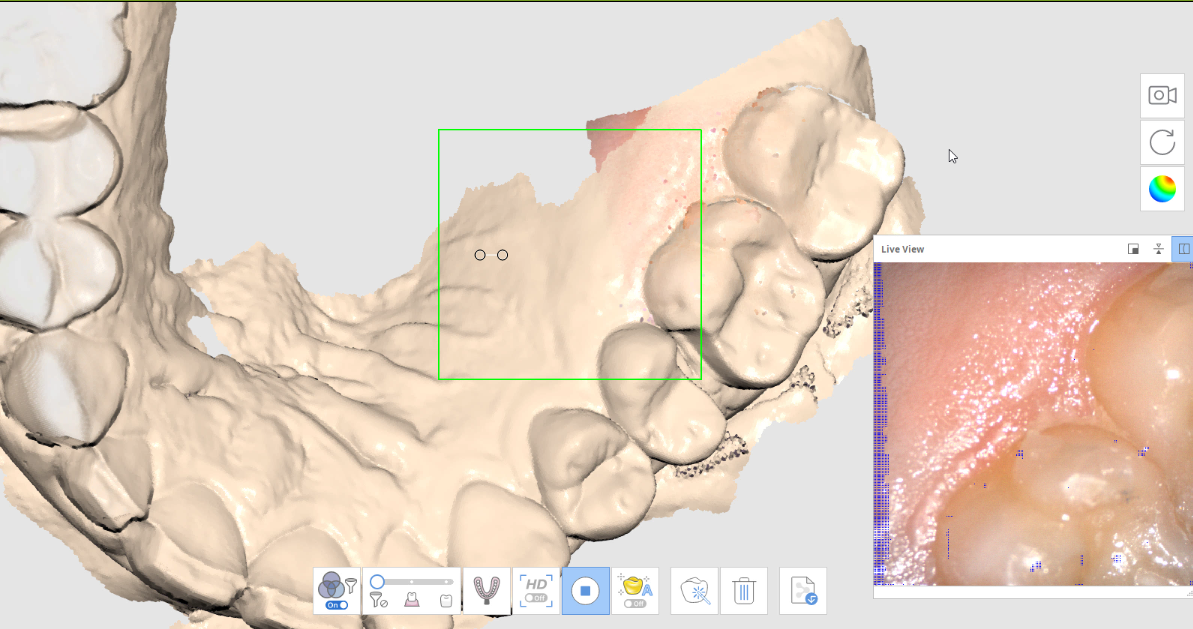

In this video we demonstrate how to use the color extraction feature of the Medit i500 scanner to displace and ignore the pesky tissue and the coronoid process that are annoying you while you try and image the distobucall area of an upper second molar

With Medit i500, there is an incredible feature where you can import a 3D model from source, even another scanner and be able to add live scans to that model. This is a first in the dental industry and has great impact for advanced users who utilize multiple models.

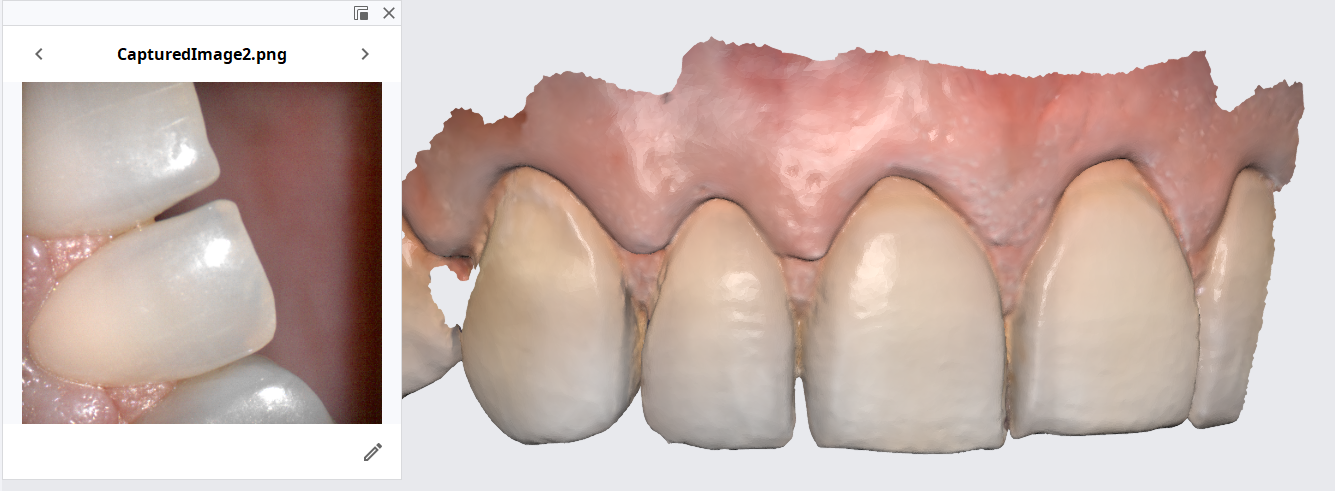

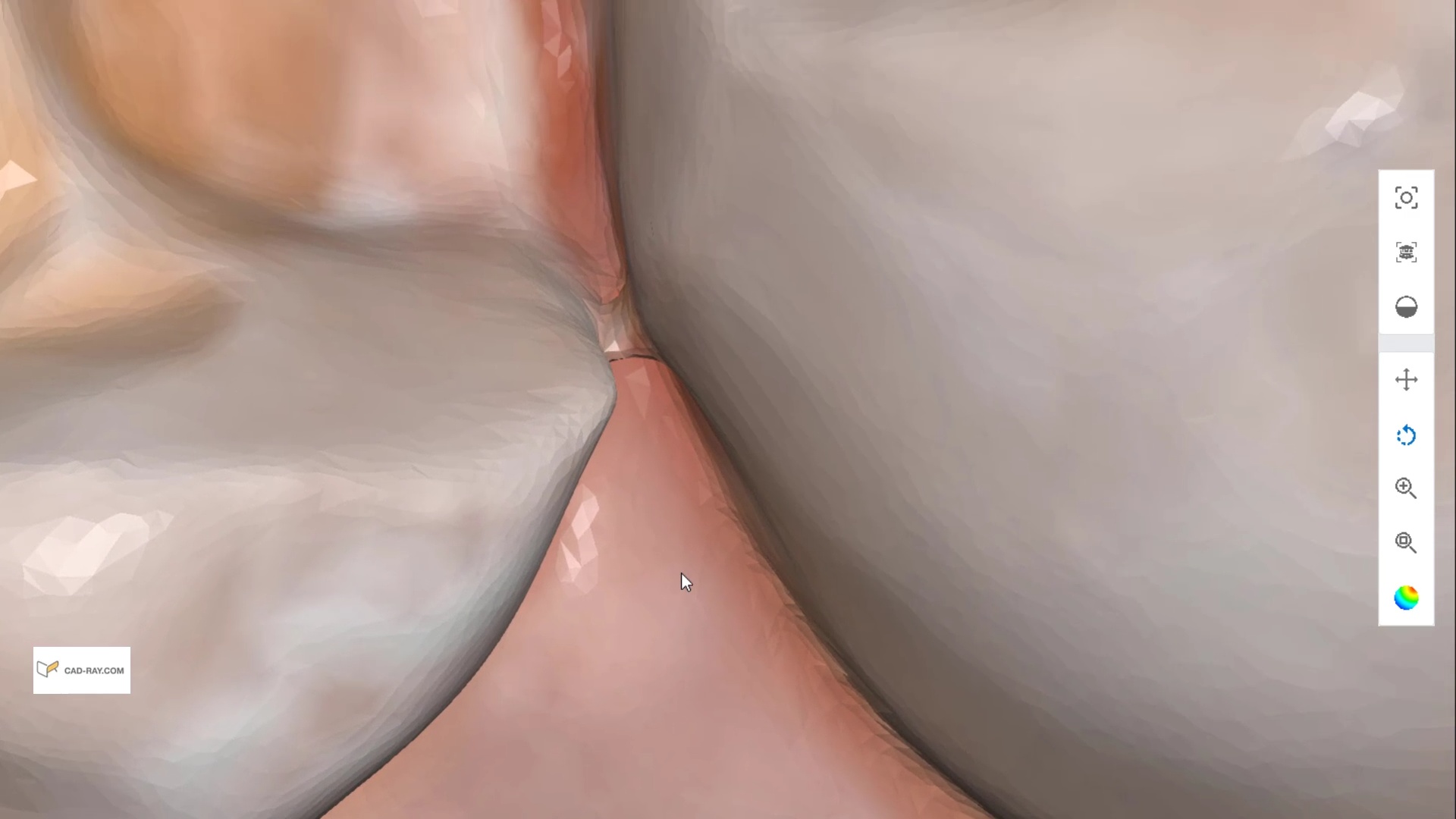

One of the most important lessons a digital dentist has to learn quickly is how to not introduce errors when scanning dentition. The most likely area when s/he can introduce errors is in the anterior area where the incisor are not only narrower than molars but can also have translucent enamel. Add just a little spacing between teeth with diastemas and you can quickly distort the accuracy of the model. This is true of ALL intra-oral scanners in the market

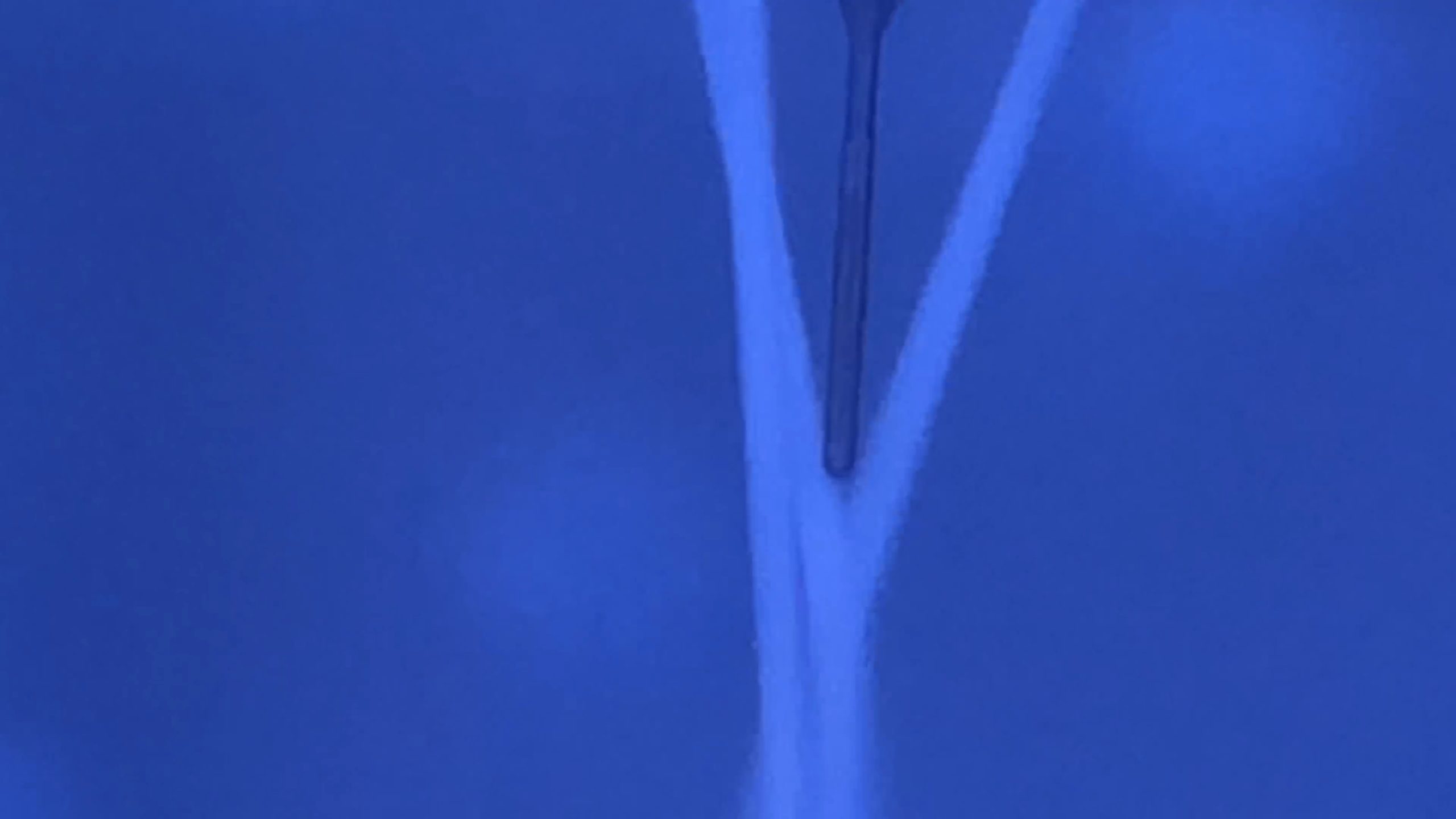

Here are some examples of how light shinning through the enamel and /or ceramic instead of bouncing back resulting in errors in model accuracy. Lesson #1 for every ios user is to know when and where they are likely to introduce error. in dentate cases, it usually is right that the transition from premolar to canine to lateral. The surface area decreases dramatically and if you have translucent enamel and / or material and / or highly reflective surfaces you can “derail” the model building. Here is an exaggerated demonstration

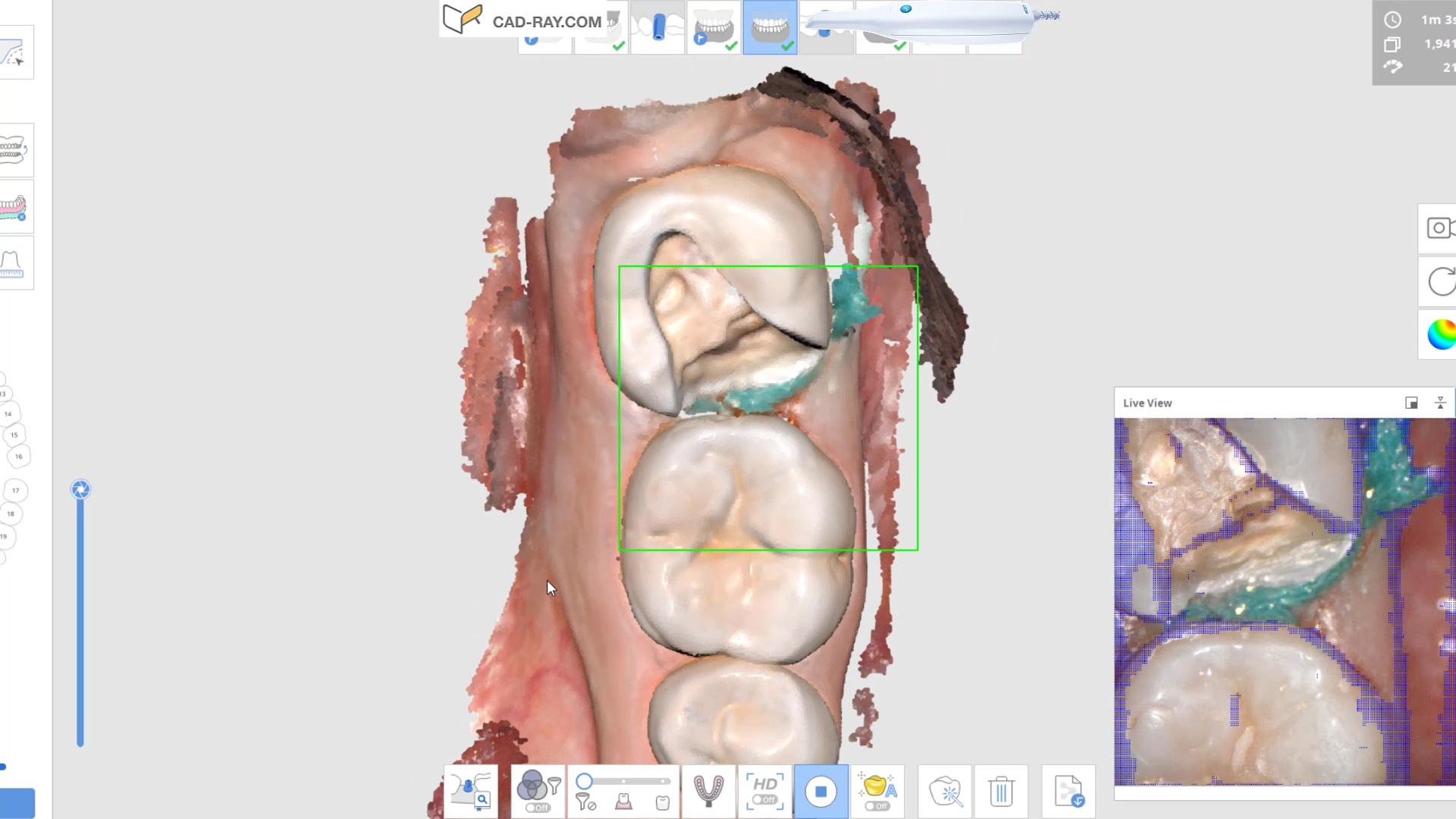

Translucent enamel can also play a role in distorting the cavosurface margins of a inlay or onlay restoration. When imaging from the occlusal, the gingiva below the margins acts as a barrier to block light transmission through the enamel, but as soon as you start to roll the camera to the buccal or lingual, and you have enamel with no substrate behind it to block light transmission, you can introduce errors in the equation with any scanner.

There are many ways to combat this which include powdering the tooth structure, using a rubber dam, or in Medit’s case, you can use the color subtraction filter. You selectively tell the scanner to ignore certain colors and you use that exact color (here, it is the color of the glove) to block light transmission through the enamel. So the software just ignores the blue, but the light is prevented from shining through reducing the errors you would introduce.

Here is another example of the distorted enamel margins on a conservative preparation and how blocking out the light from travelling through the tooth structure leads to crisp visualization of margins without any distortion or artifact

can you explain why we see blurred margins and artifact/distortion between the 2 centrals while in the second image the…

Posted by Armen Mirzayan on Sunday, March 6, 2022

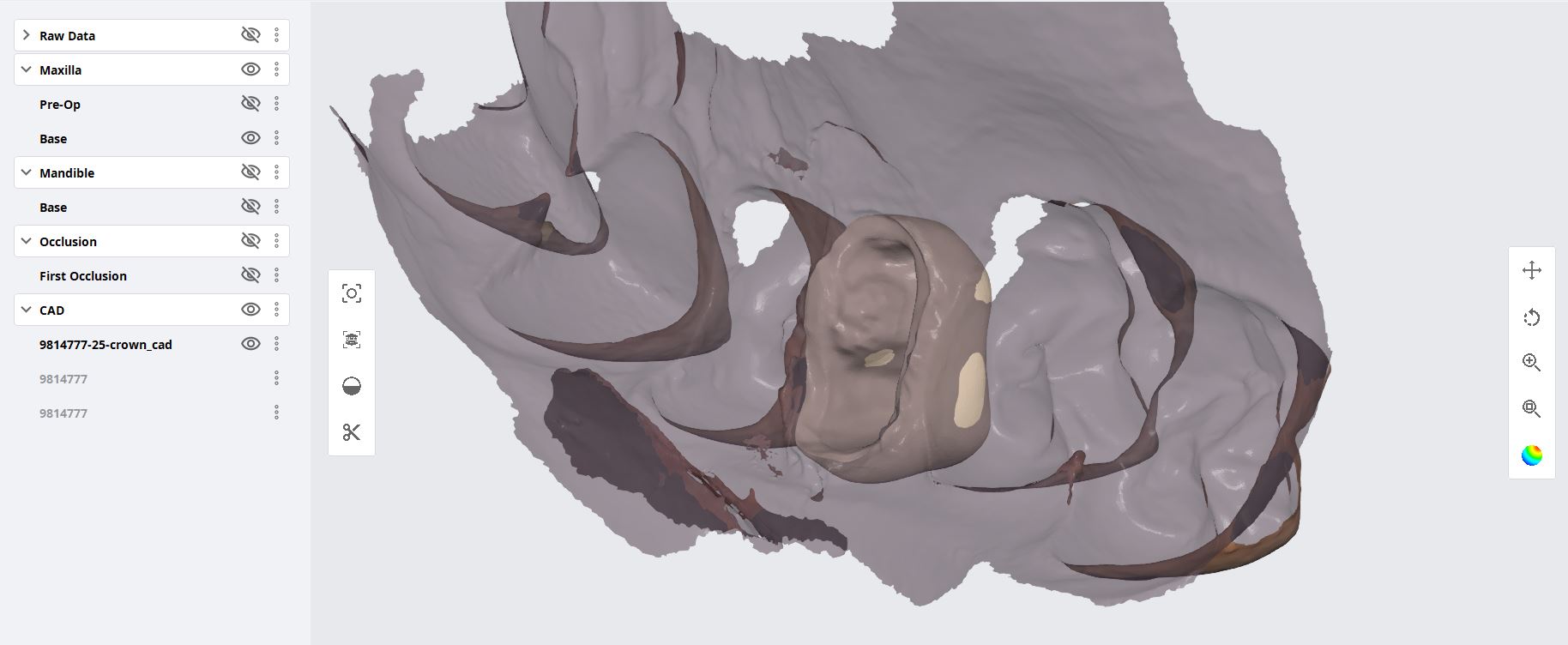

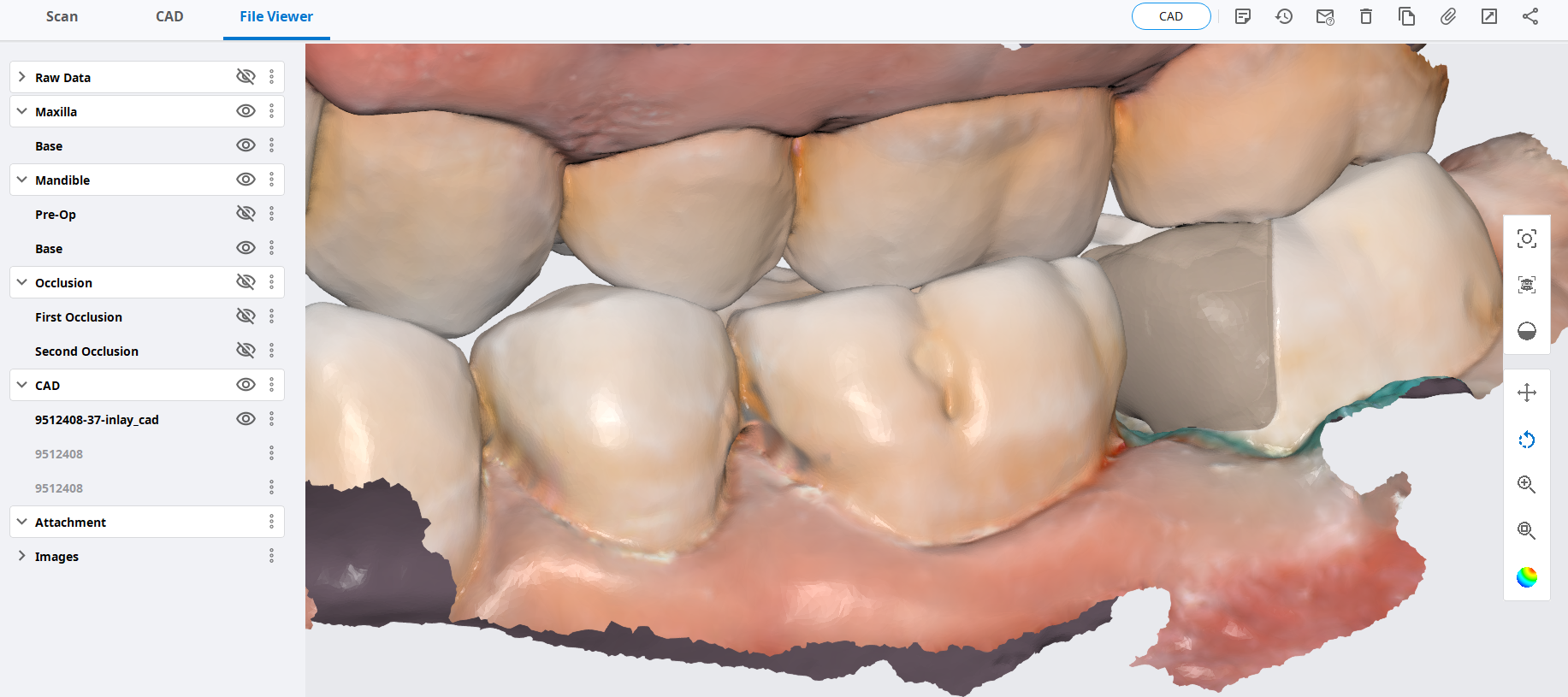

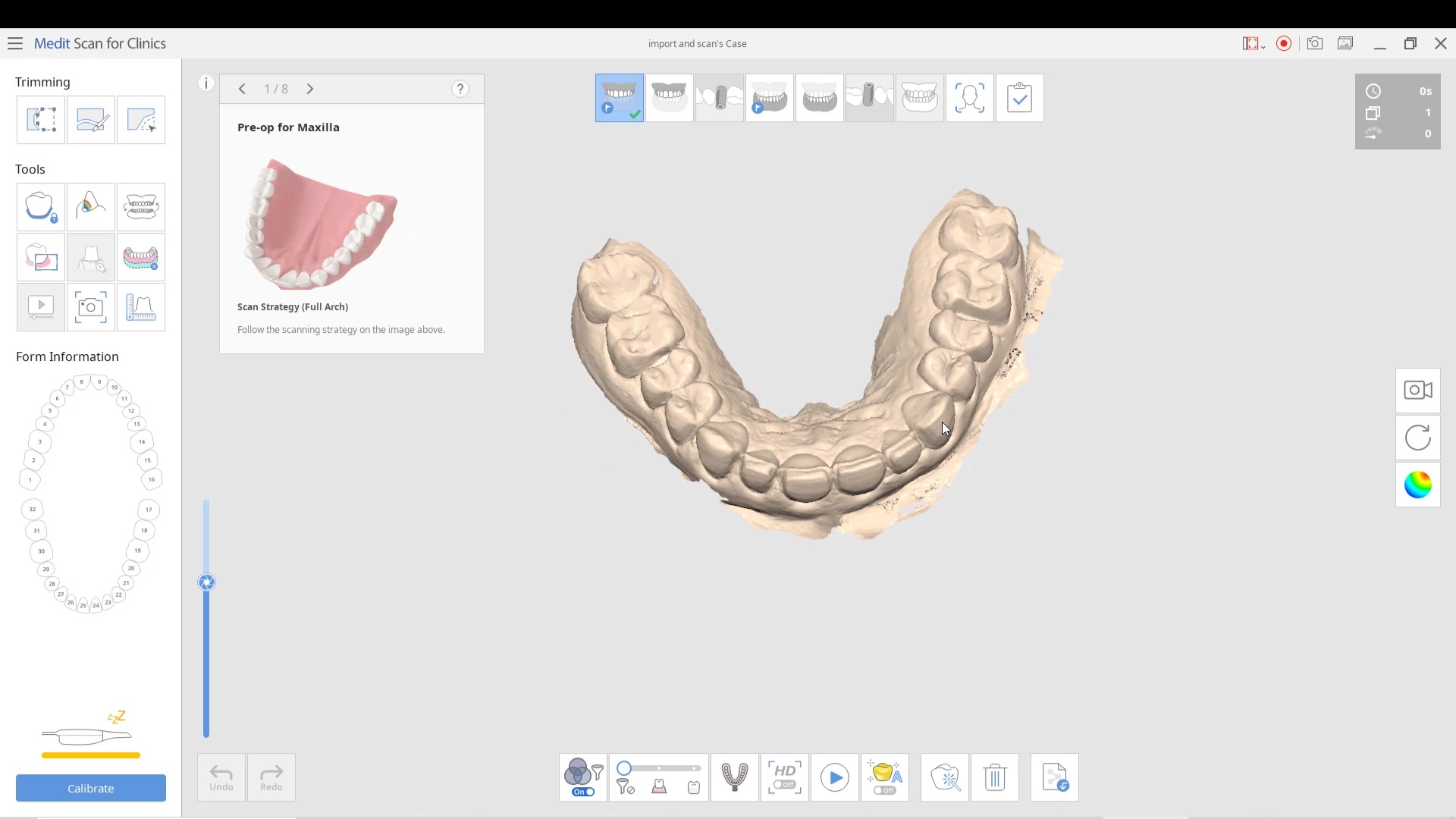

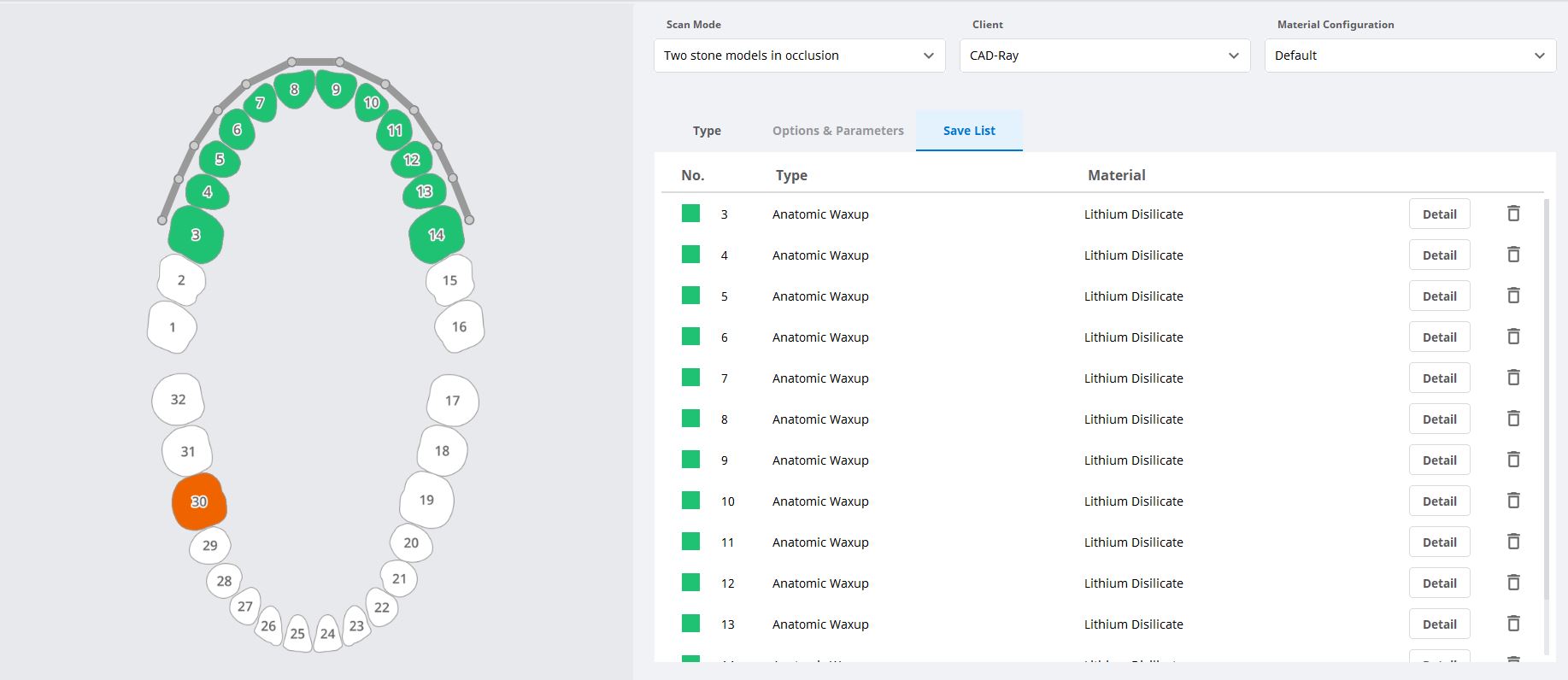

For advanced users of meditlink software, you can skip filling out the Rx form and go straight into scanning. But make sure to properly fill out the CAD Rx form so that all the necessary models are imported into the design software. If you don’t designate the opposing or the Pre-op / Wax-Up in the form, they will not be part of the design equation. Also, this video shows how to select multiple restorations at once.

A good maintenances practice for any milling machine is to check that the tip of the drill is getting adequate water, otherwise you may see sparks flying as you are essentially dry milling material that is not supposed to be dry milled leading to drill and block breakage. We recommend that you run the water for a minute or two at the start of the day and check and make sure the spray is right on the tip of the drill. A simple ortho wire can help unclog the ports and redirect the water spray to where it belongs.

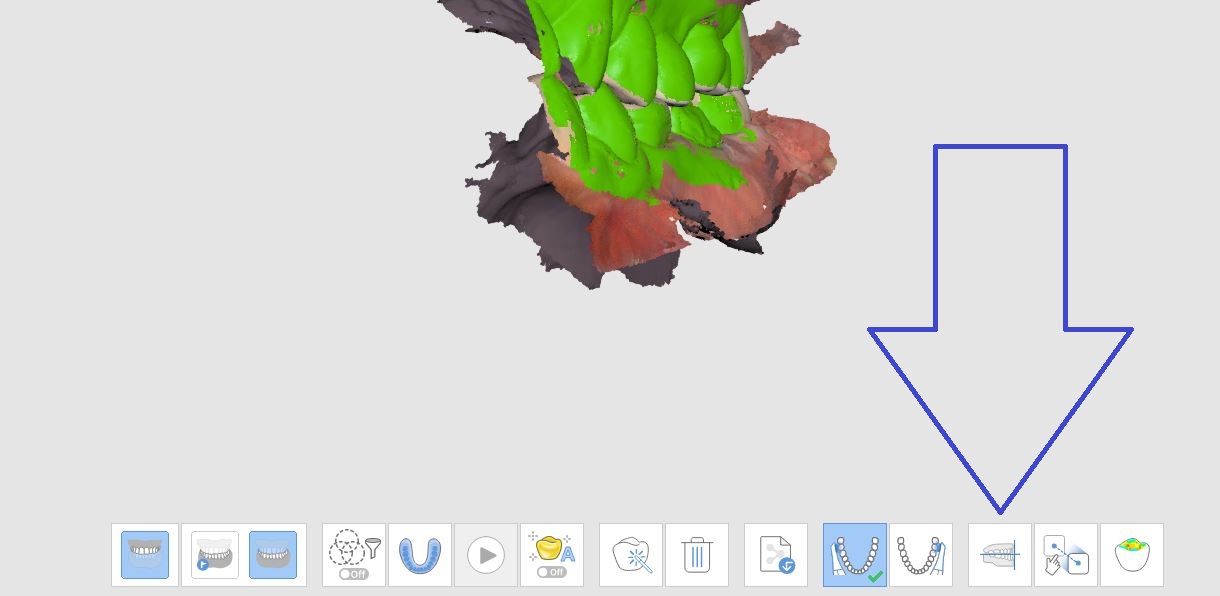

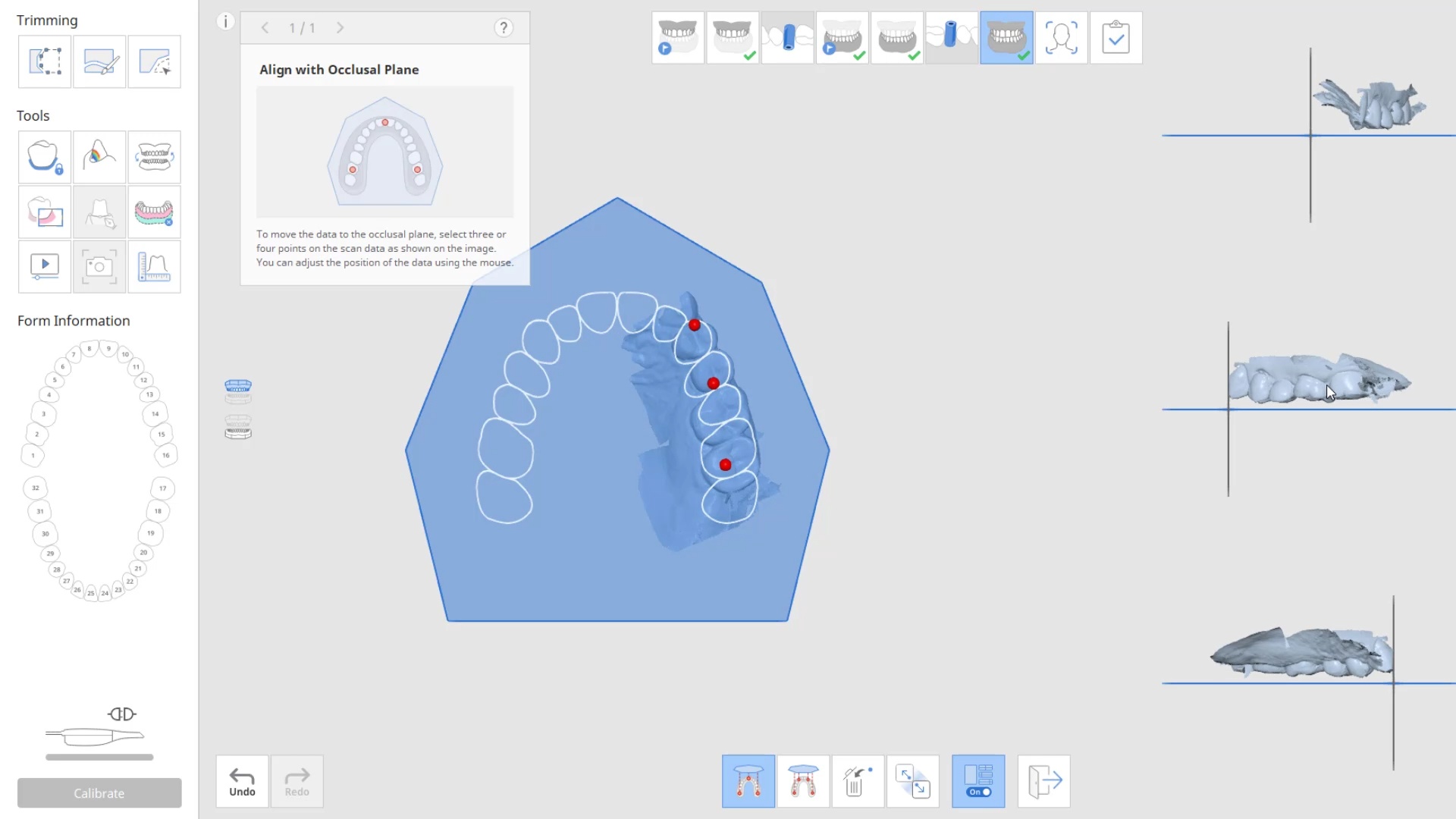

Setting the occlusal plane in the native medit software will allow for much nicer initial proposals in the CAD software

At CAD-Ray, we have now designed over 20,000 implant cases since 2013. One of the most common requests we get is from doctors doing full arches and their desires to reduce the conversion time. A simple thought to keep in mind is that A LOT can be derived from the actual implant plan, even if you don’t do the surgery guided. You can extract the digital implant positions and fabricate temps and based on your level of experience, your conversion / temporary time can drastically reduce.

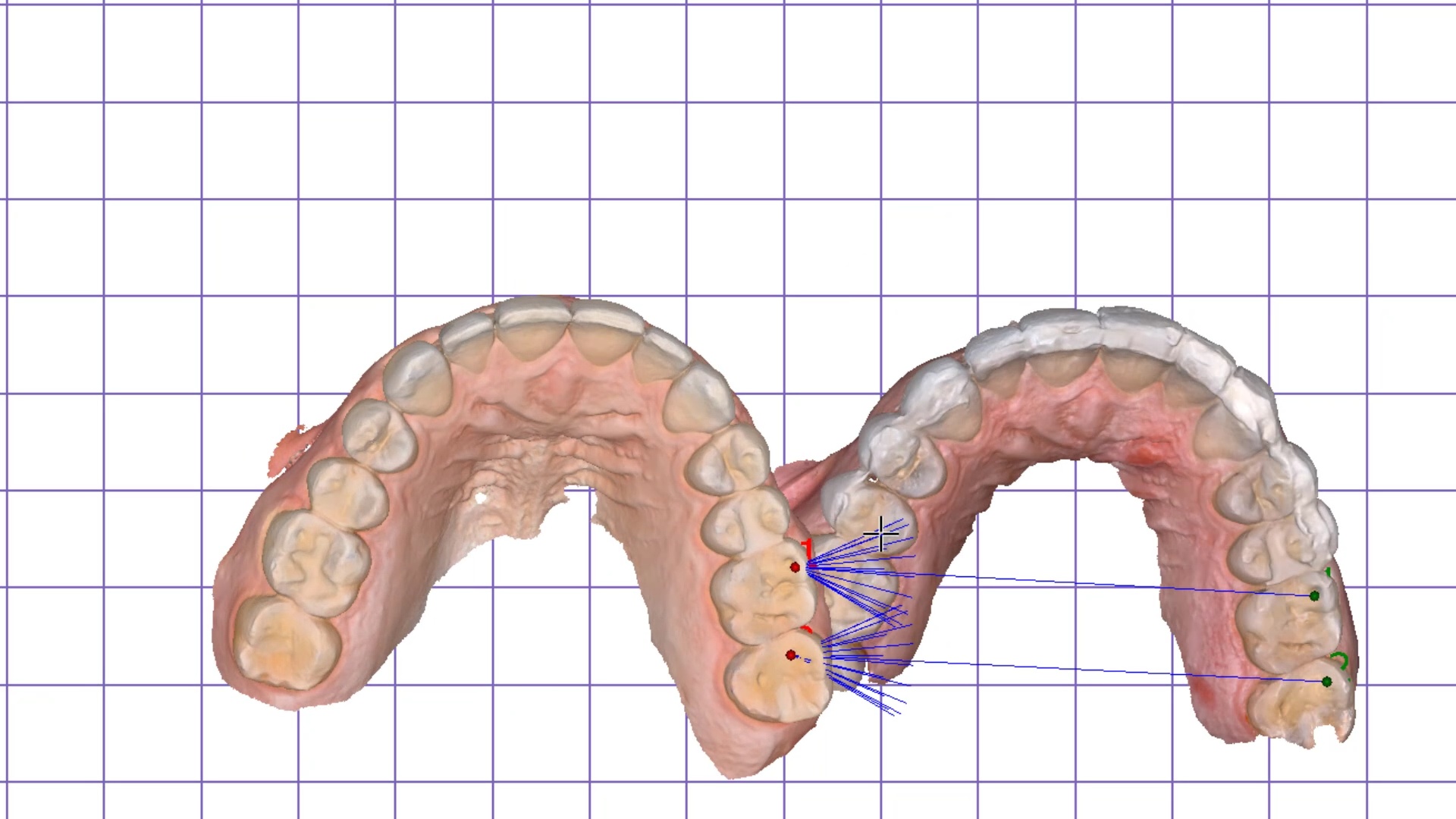

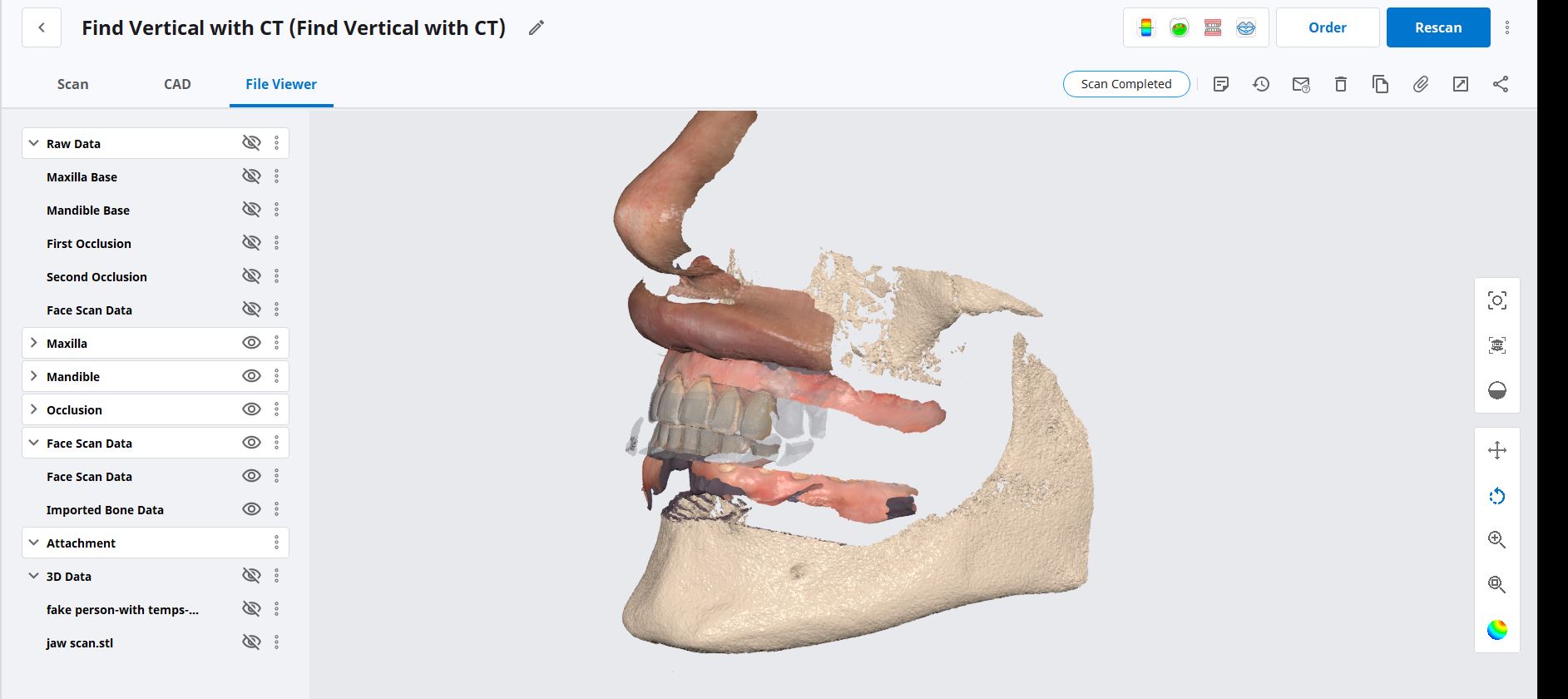

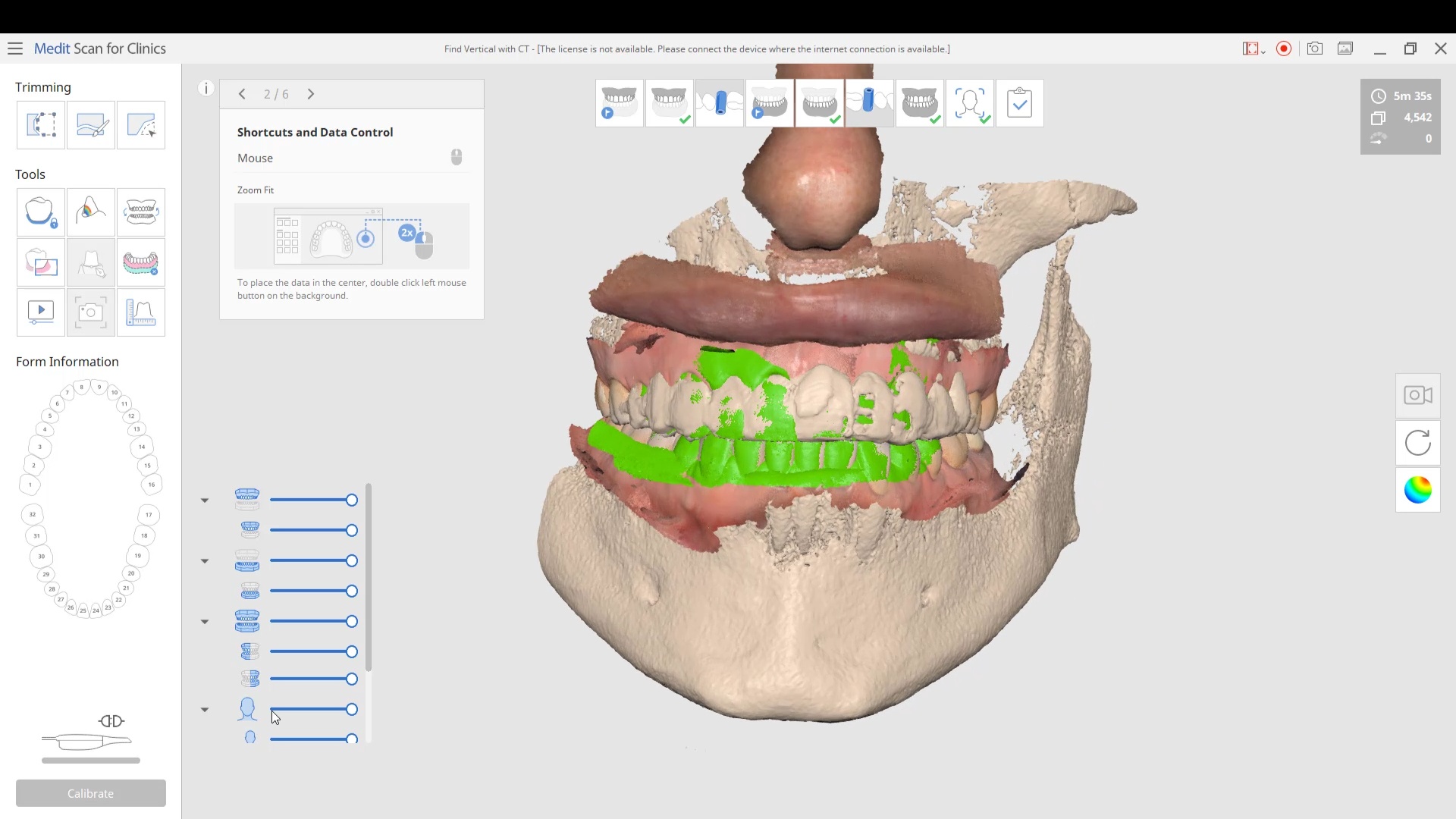

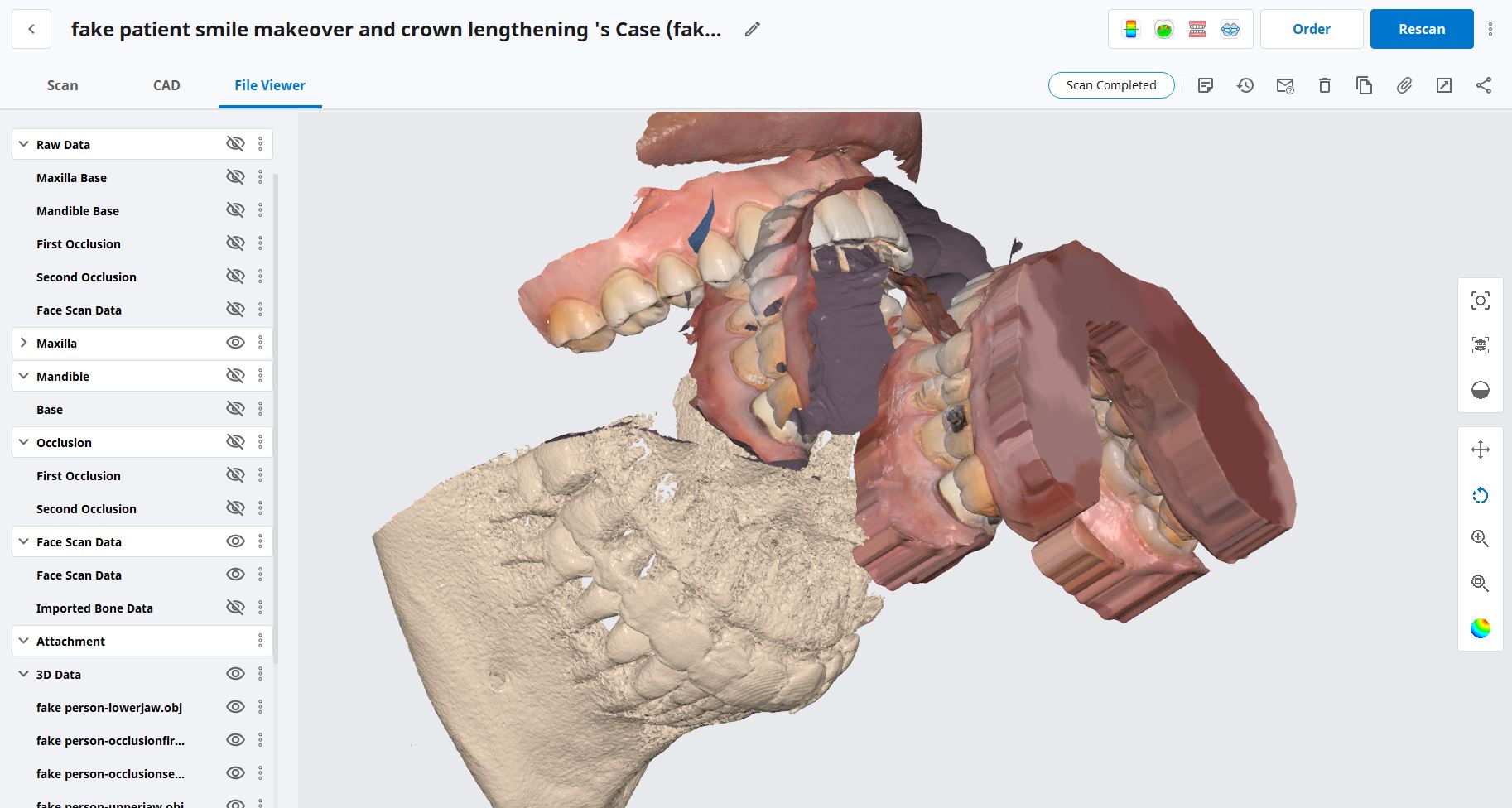

Another very helpful matter to keep in mind is a concept we preach a lot at our courses. It deals with relating models to each other, both automatically and manually. This can be a CT scan to an intra-oral scan, or a pre-op to a post op. You just have to find redundant landmarks for the software to merge the models together. One thing to keep in mind, particularly with the Medit i500 is that when you merge models to each other and process it, their relationship to each other is preserved.

There is a lot of benefit that can be derived from that. For example, in this video, we have the dicoms converted to surface STL’s which is very easy to do. We also have the intra-oral scan merged to that stl file. You can digitally extract the teeth and do bone reductions, and if you are ever in a bind where you lost track of the vertical dimension, you can use the jaws as the means to related the preop to post-op. Or you can even use the nose if you are really desperate.

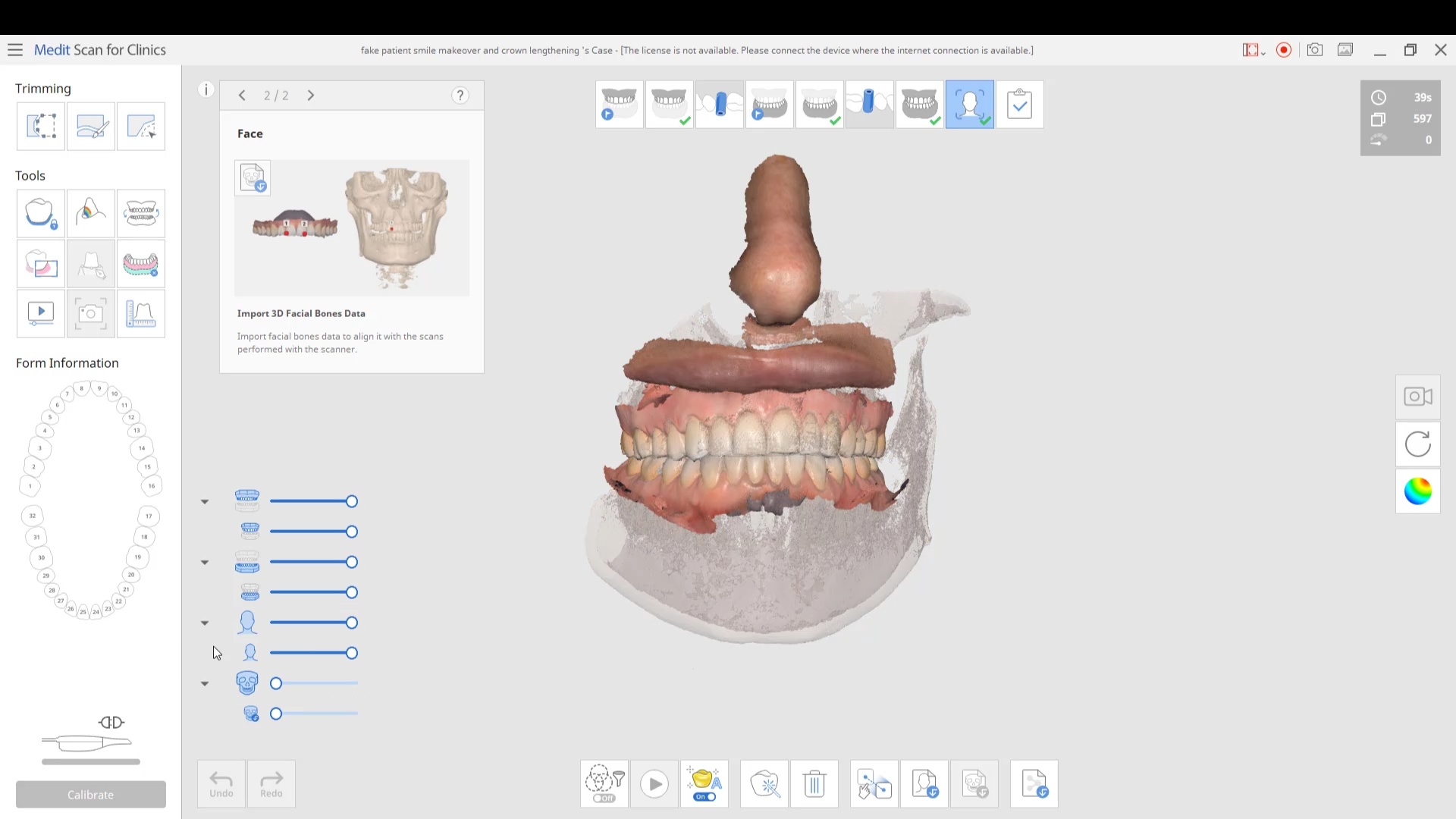

in this case we import multiple models, videos, CT scans, and Face Scans so that our users can utilize all of these features. Click here to enter the member’s section to download the whole case and design along

here is a list of why the Medit Artificial Intelligent Implant Suprastructure Identification System is significantly more advantageous over all other cadcam systems.

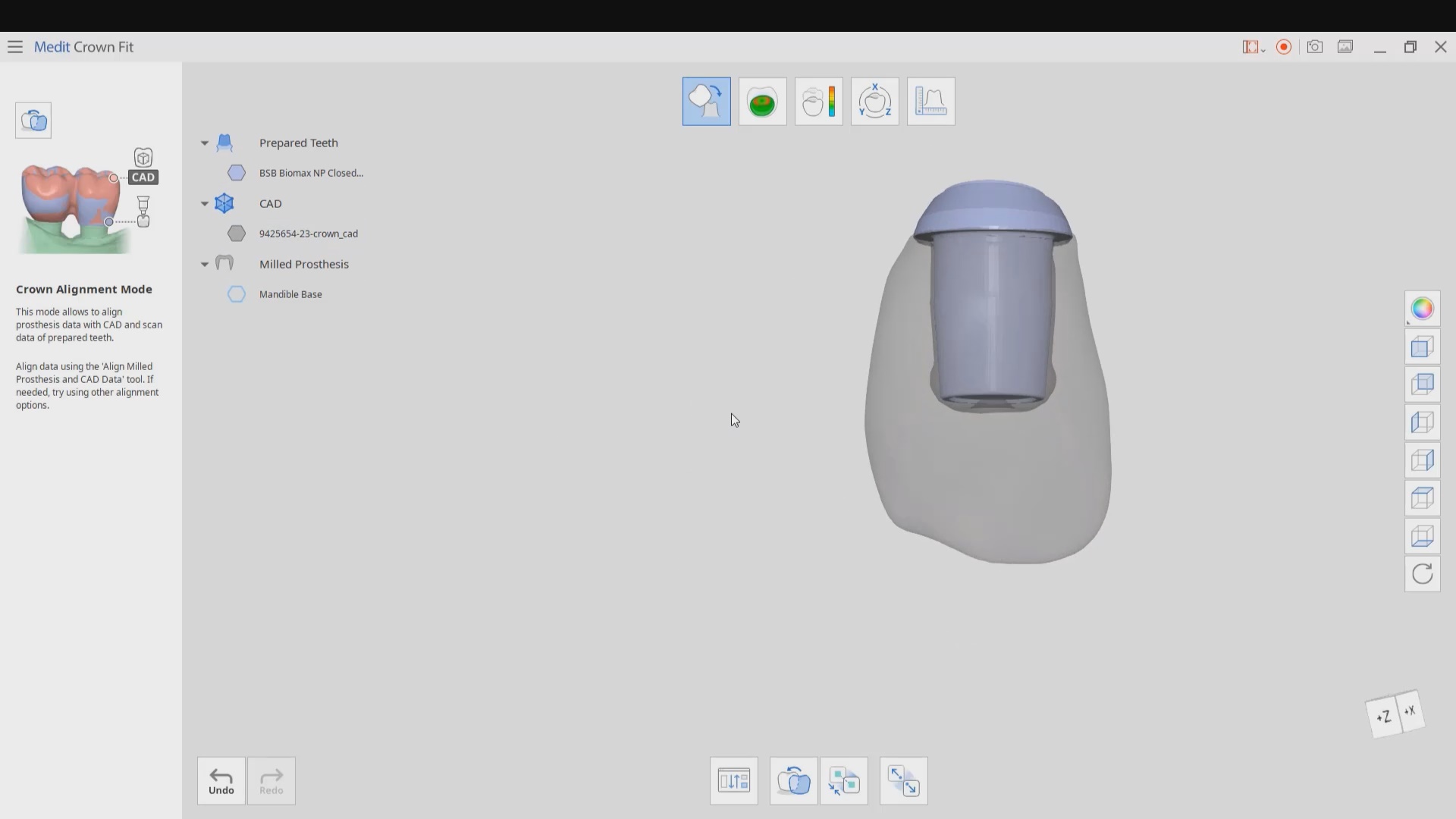

With Medit’s Crown Fit function, you can see exactly how much cement is required to seat the restoration and how well it is adapted to the tibase.

You must be logged in to post a comment.