Printing

Additive manufacturing is very popular in the dental profession now where models can be printed and appliances can be fabricated inexpensively and rather quickly. Long term, with the advancement of the technology, permanent tooth / body parts can be replaced from this process.

Milling

Subtractive manufacturing has been readily used to derive dental and implant prosthetics for decades. The level of quality currently supersedes that of printing for reliability of materials

Photogrammetry

In simple terms, photogrammetry is the compilation of multiple images and pictures that can render a 3D model. The first example is simple app that is used with a smart photo that scans a dental mold or impression and rendering a workable model. Although the technology for such specific use needs to be further developed, it is a very promising technology that can impact the dental field.

For advanced uses a very specific stereo imaging system can be used to accurately chart object locations within microns of accuracy. This level of precision is in high demand for very expensive and elective procedures. Click this link for more detail

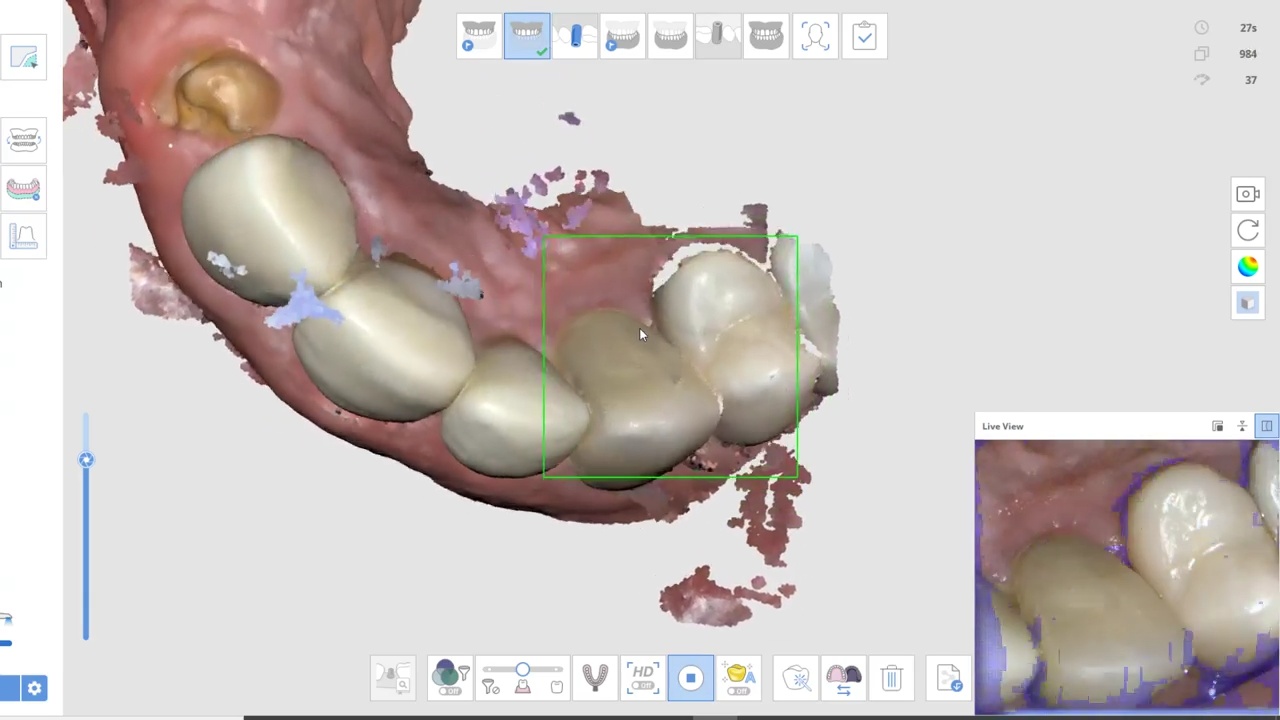

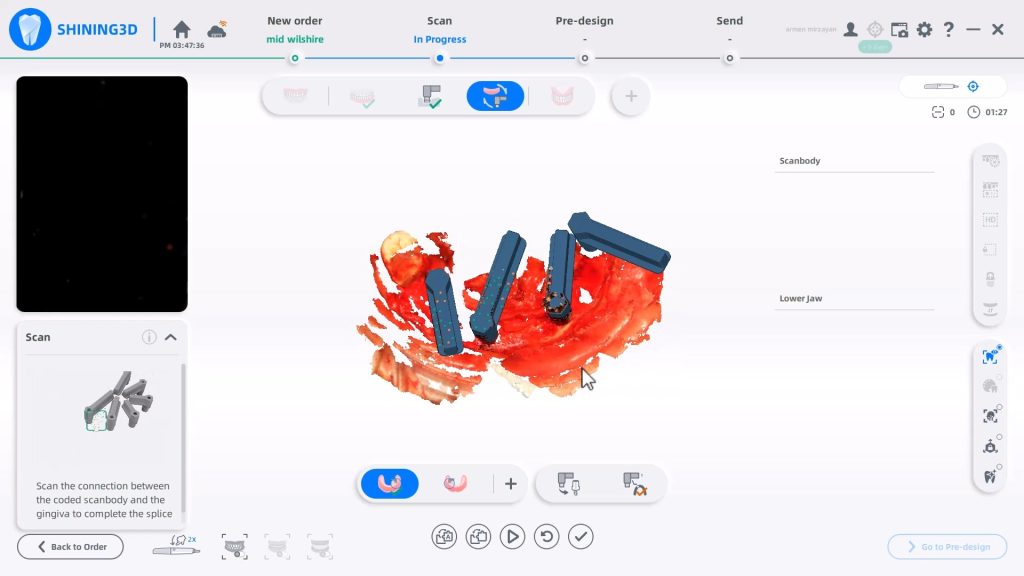

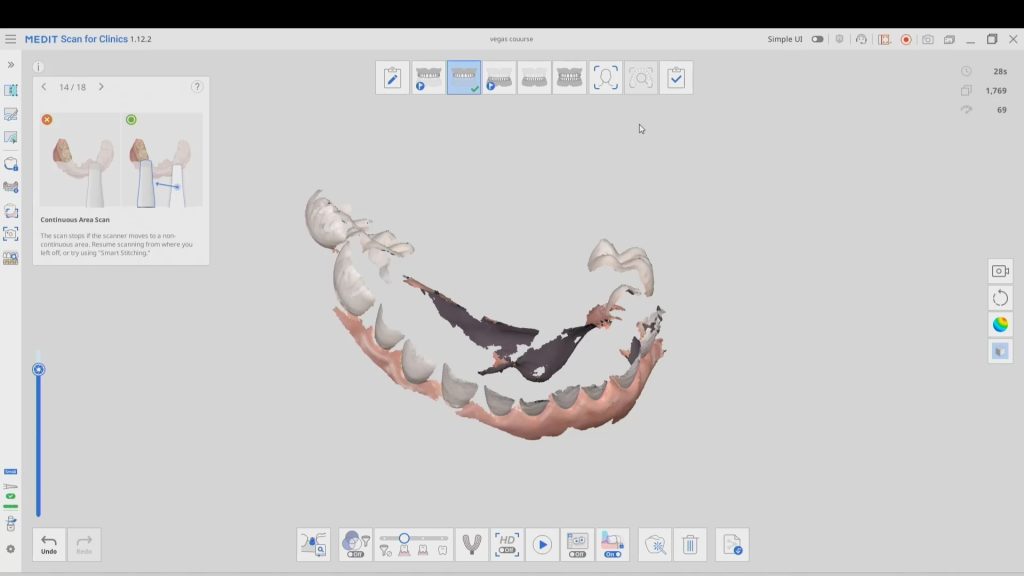

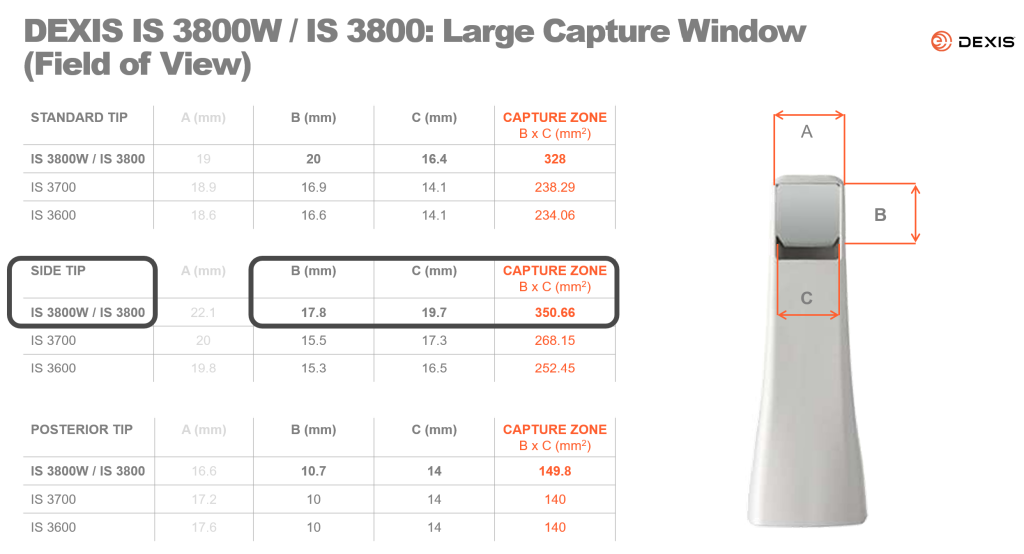

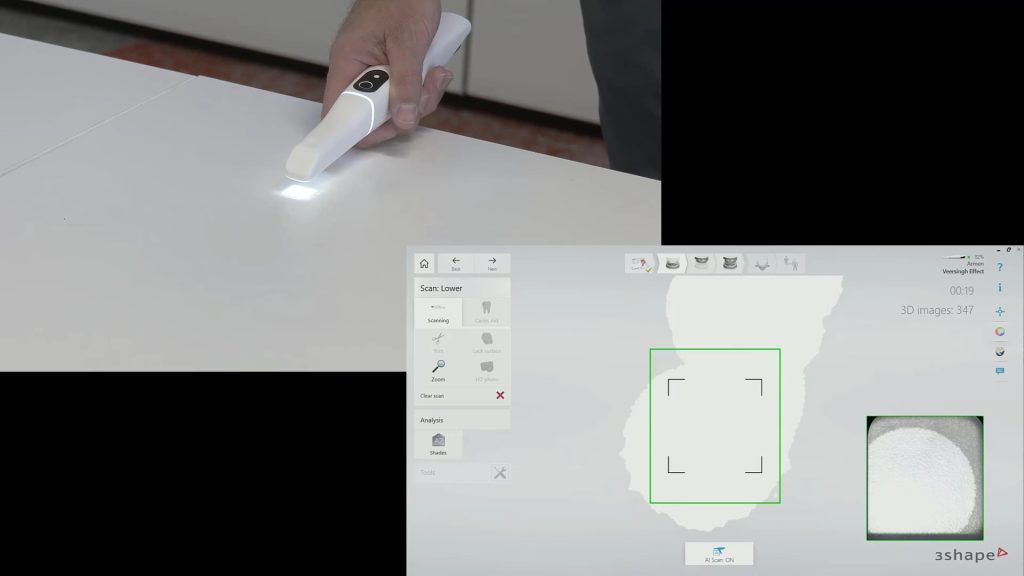

Intra-Oral Scanning

Most people are familiar with the traditional dental molds. Intraoral scanner are devices that project light onto the dentition and 2 cameras in the device capture thousands of images and the software algorithm converts them into functional 3D models. Here are a couple of simple videos that demonstrate the process.

Desktop Scanning

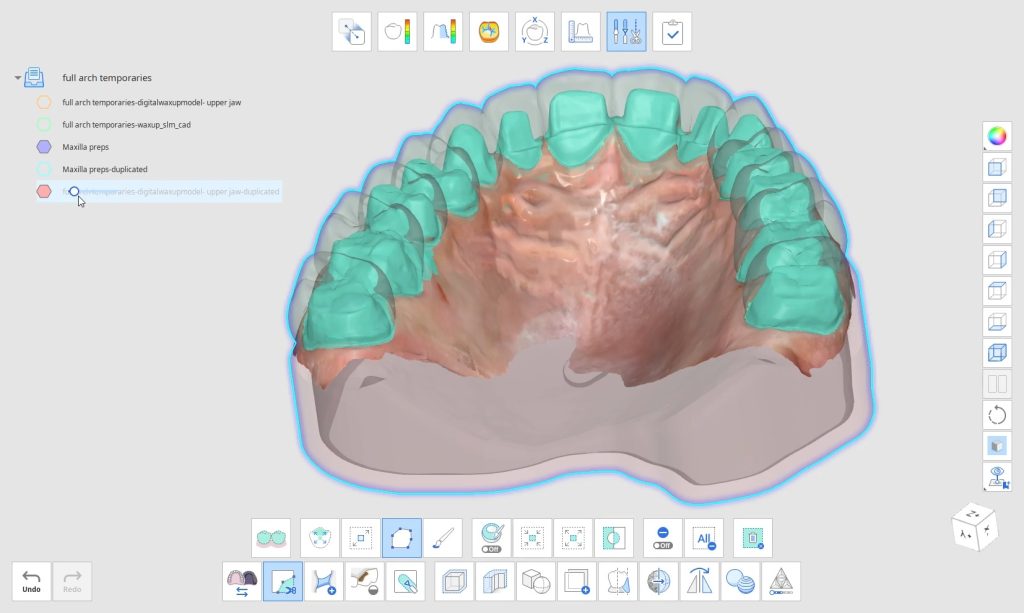

CAD (Computer Aided Design)

CAM (Computer Aided Manufacturing

You must be logged in to post a comment.