Medit User Crushes Full Arch Impressions After Watching Our Tutorials

Digital Dental Impressions with Intra-Oral and Desktop Scanners

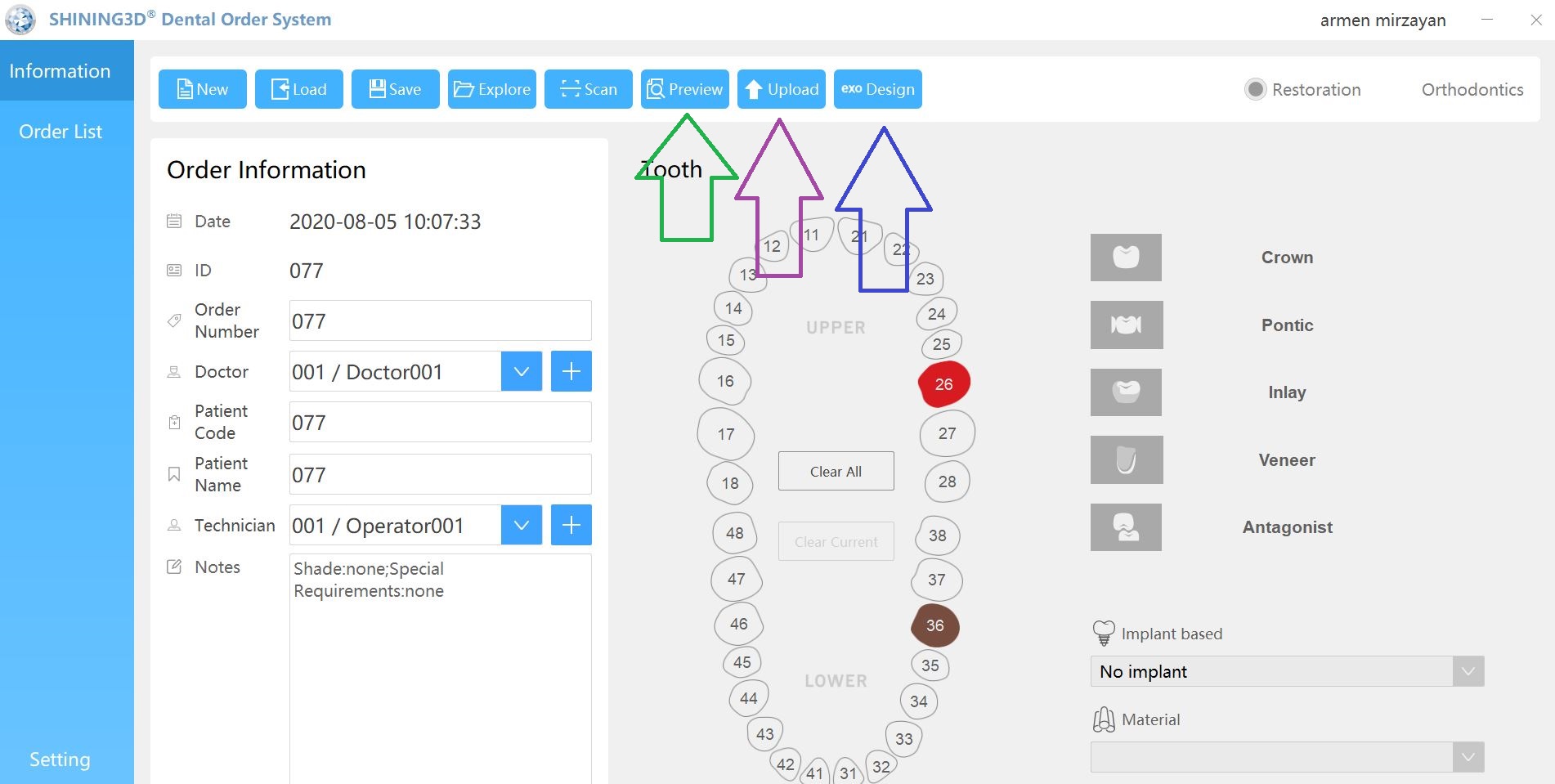

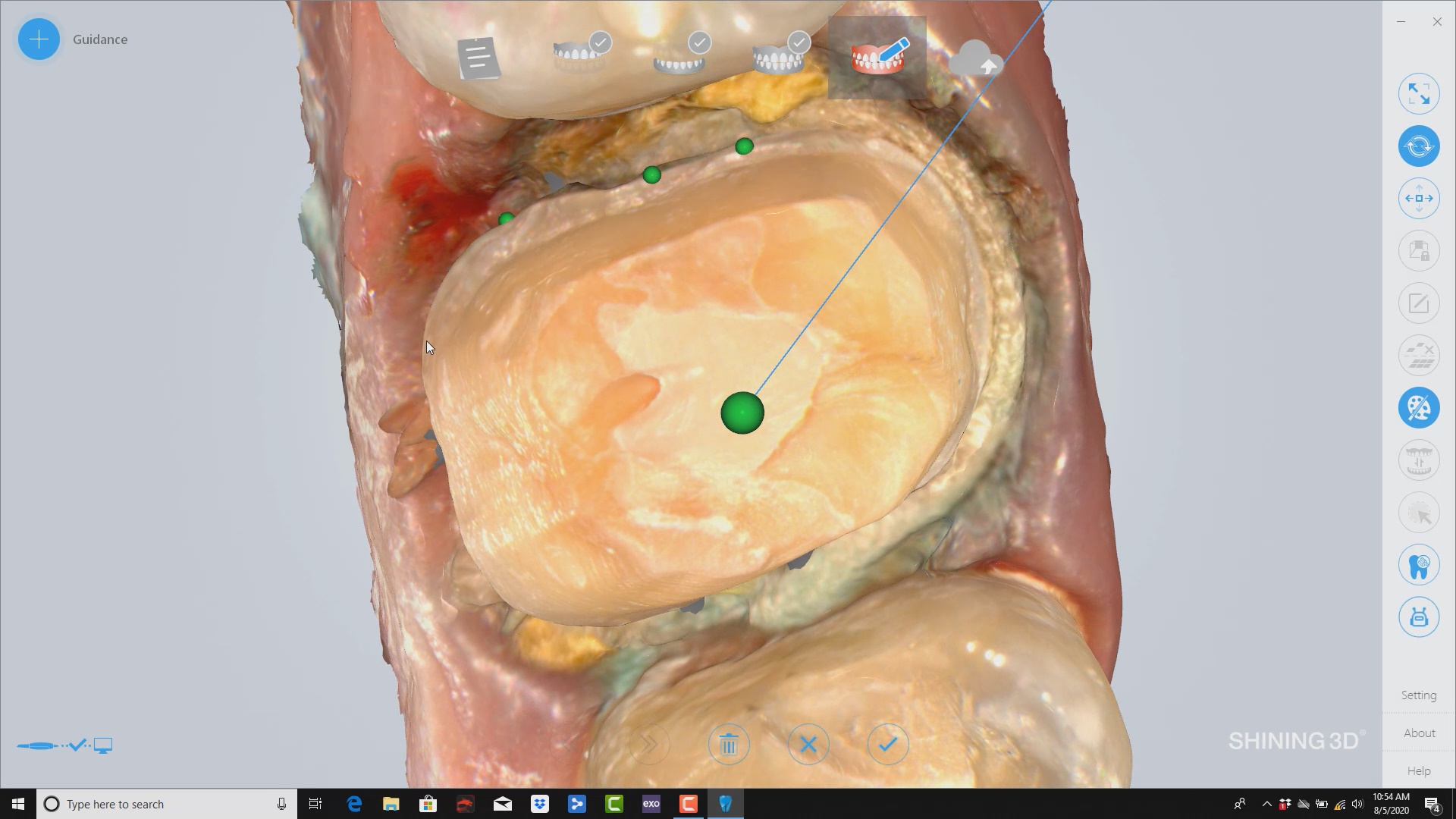

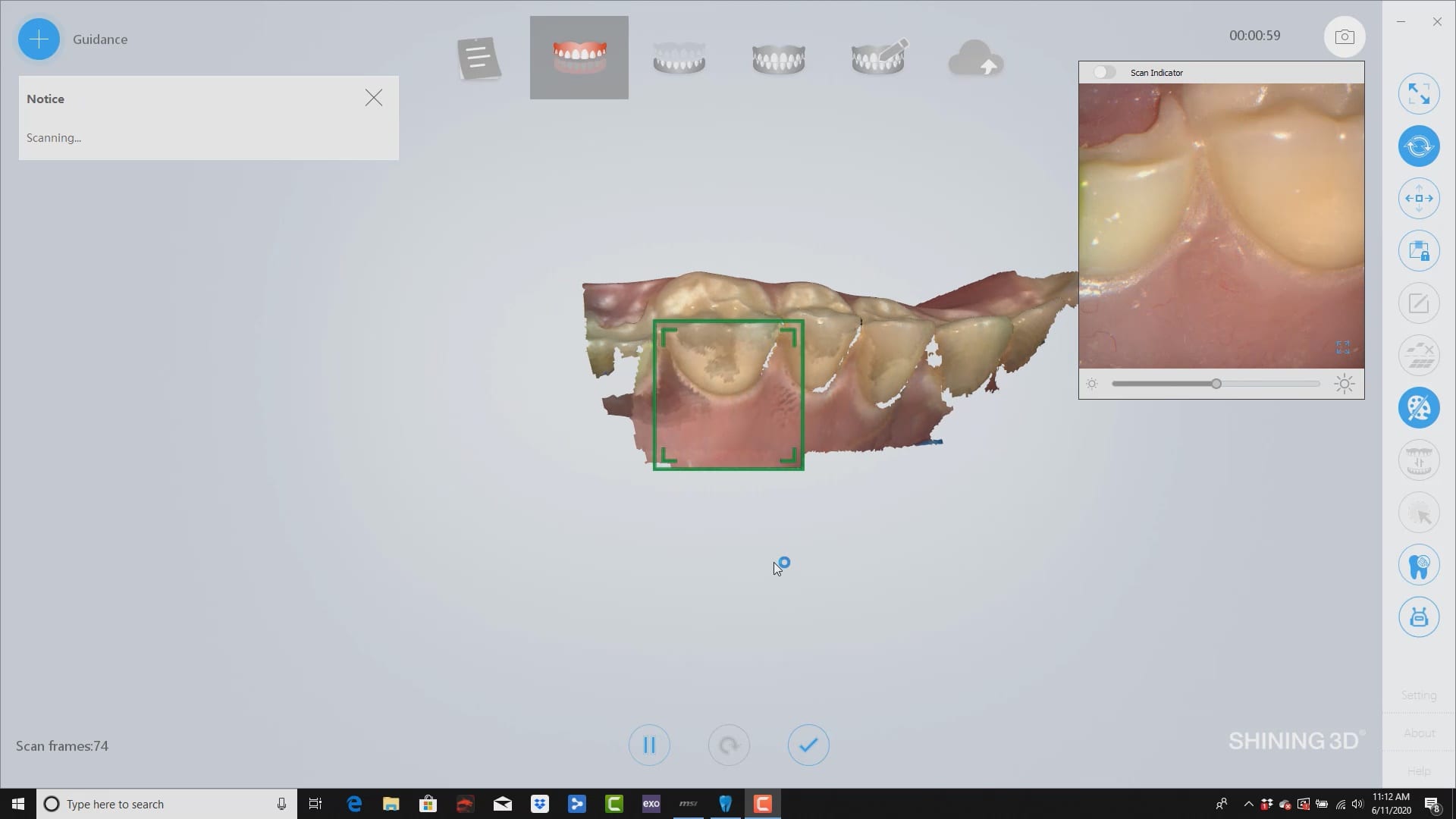

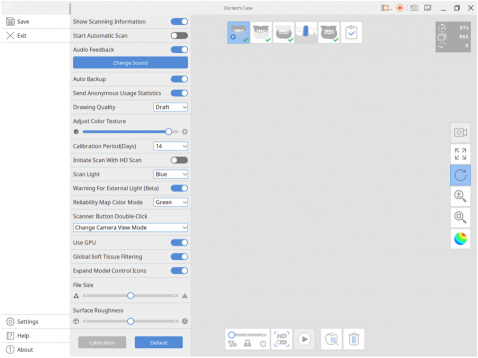

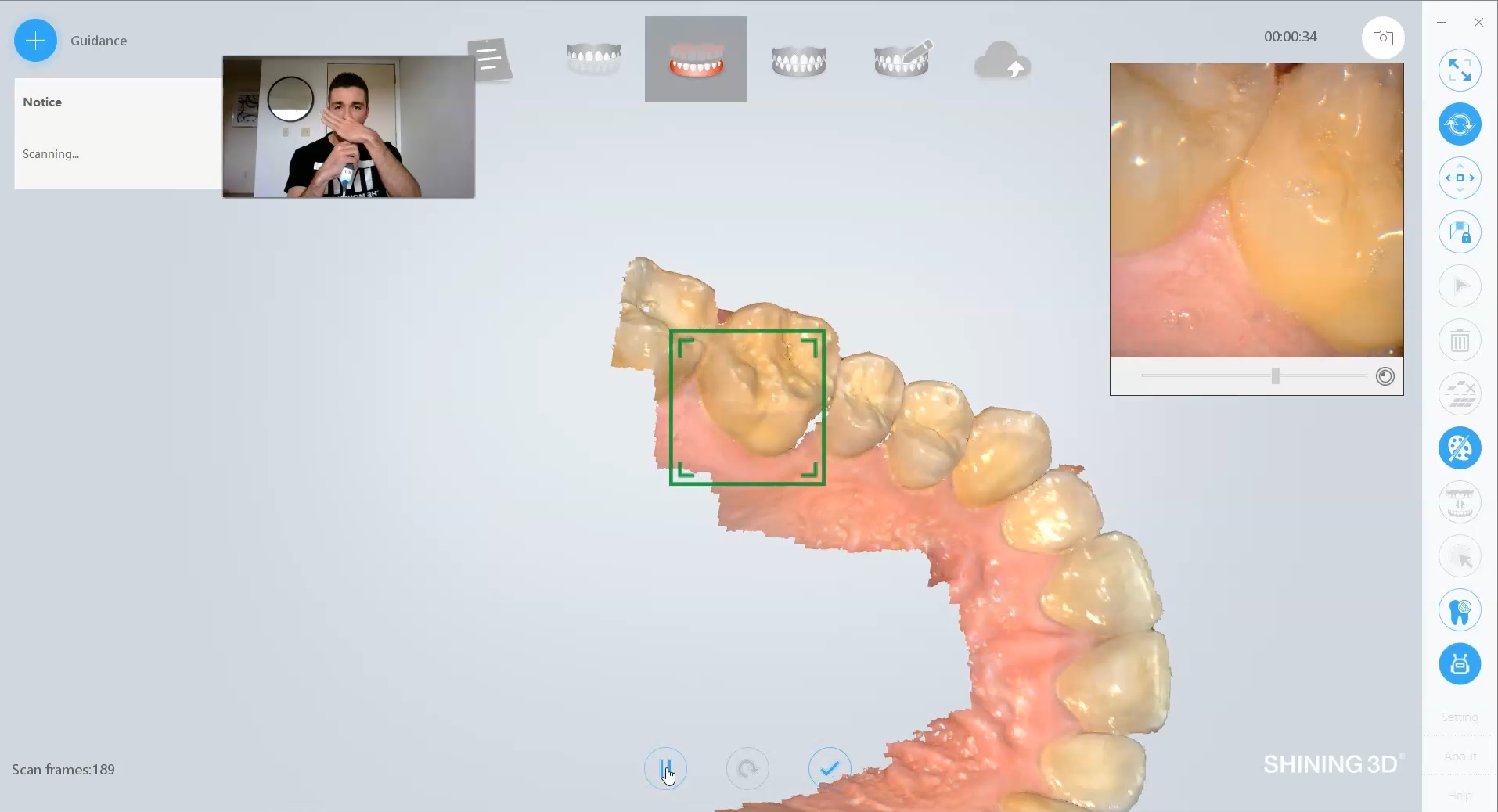

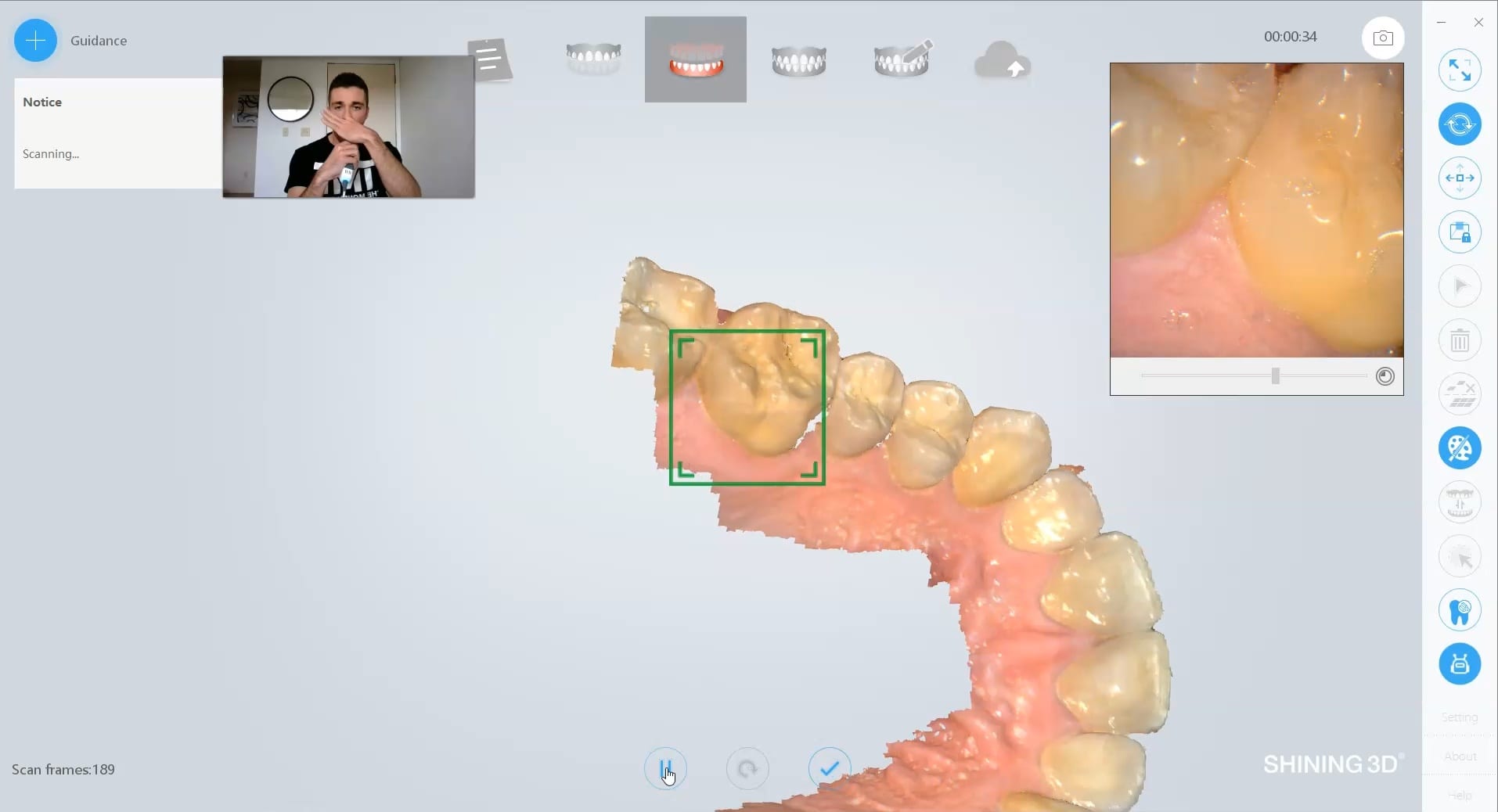

Shining3d has a projector and a single camera that takes photos of the surfaces it is scanning. at first, you may think this is a shortcoming, but in many ways, it dramatically reduces errors a new user can introduce.

in the early days of cerec, all you needed to do was capture the margins and the area above the height of contours of the adjacent teeth. This made the try-in and the contacts really easy as the design software just dropped straight a straight wall down to make contacts to. same concept here!

also, after you image and place margins, A SINGLE CLICK takes you to design software where you can finish the case and mill it right away.

One of the big limitations of CEREC (a registered trademark of denstply sirona) with tibases and implant crowns is that it is limited to very few implant lines and the antirotational notch can just ruin your day as it needs to go into a specific location. You also have to deal with making sure the tibase is seated all the way and the scanbody is properly indexed. The one benefit is that you are dealing with just crown and bridge and you do not need to know implant position or timing at all when doing the design.

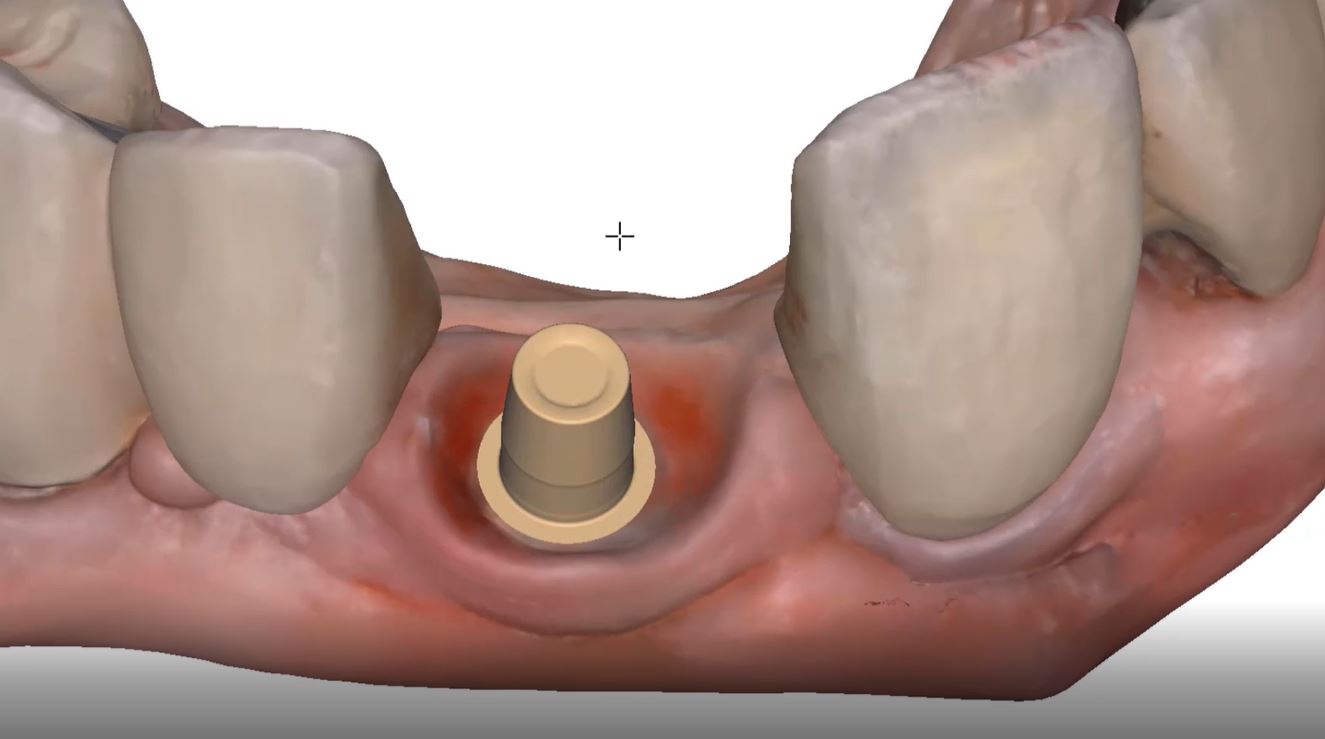

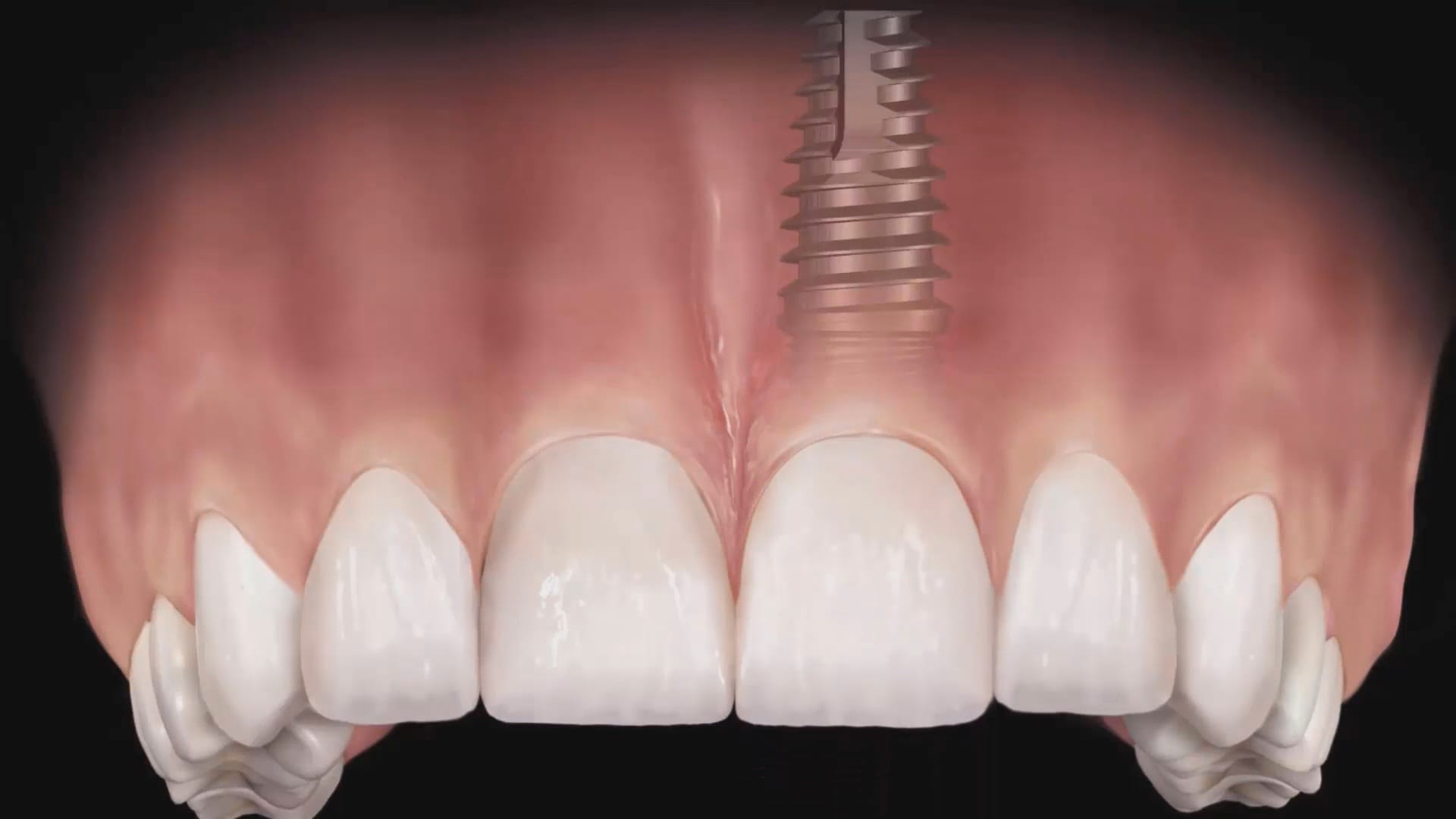

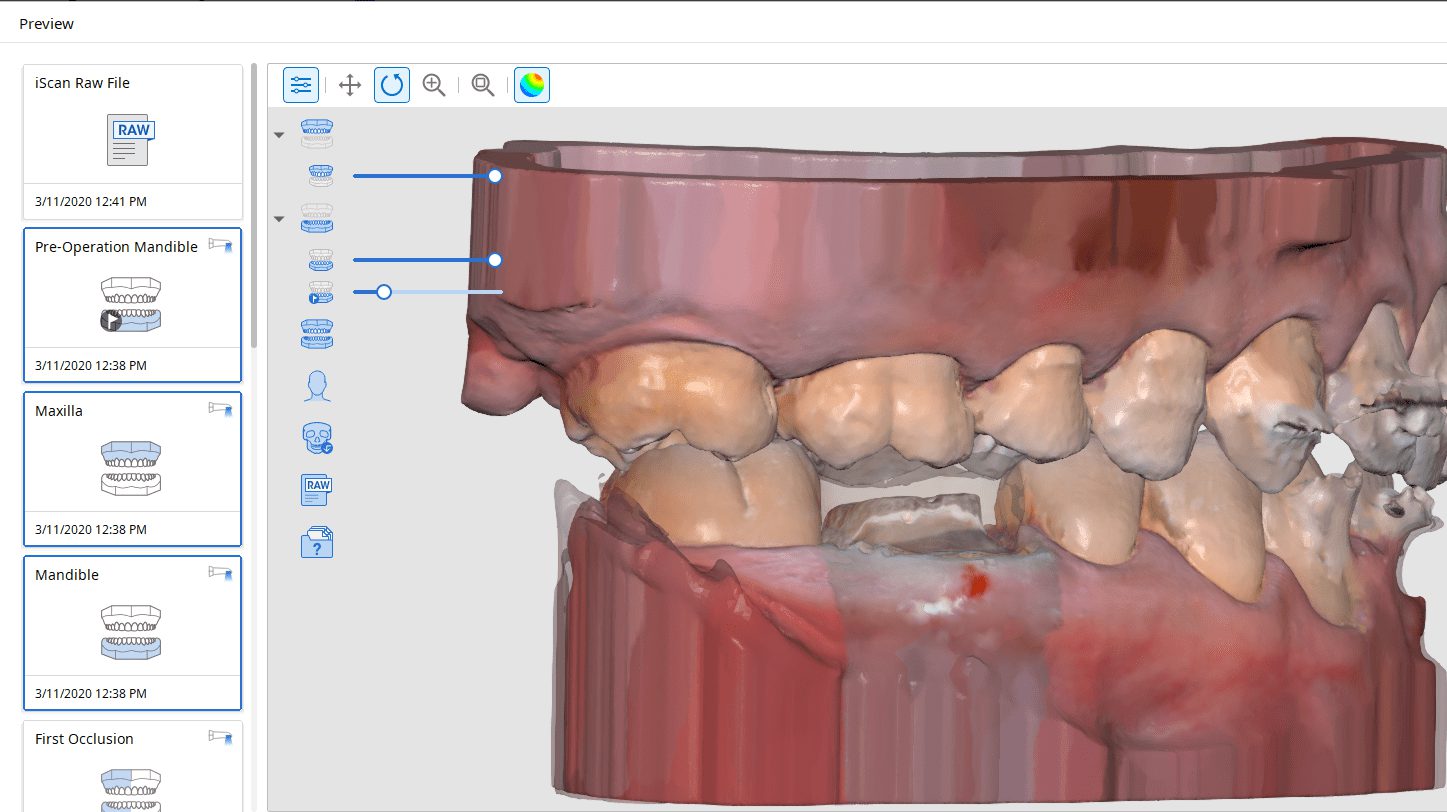

In this case, we demonstrate how we utilize the Medit i500 to capture a Tibase from Blueskybio, Biomax NP Conical Connection. Once the tibase is seated, we simply start scanning and then use the artificial intelligent implant suprastructure identification system to identify the location of the tibase. This in essence allows you to capture your margins OUTSIDE the mouth and you don’t have to bother with imaging the tibase, which is highly reflective in the patient’s mouth.

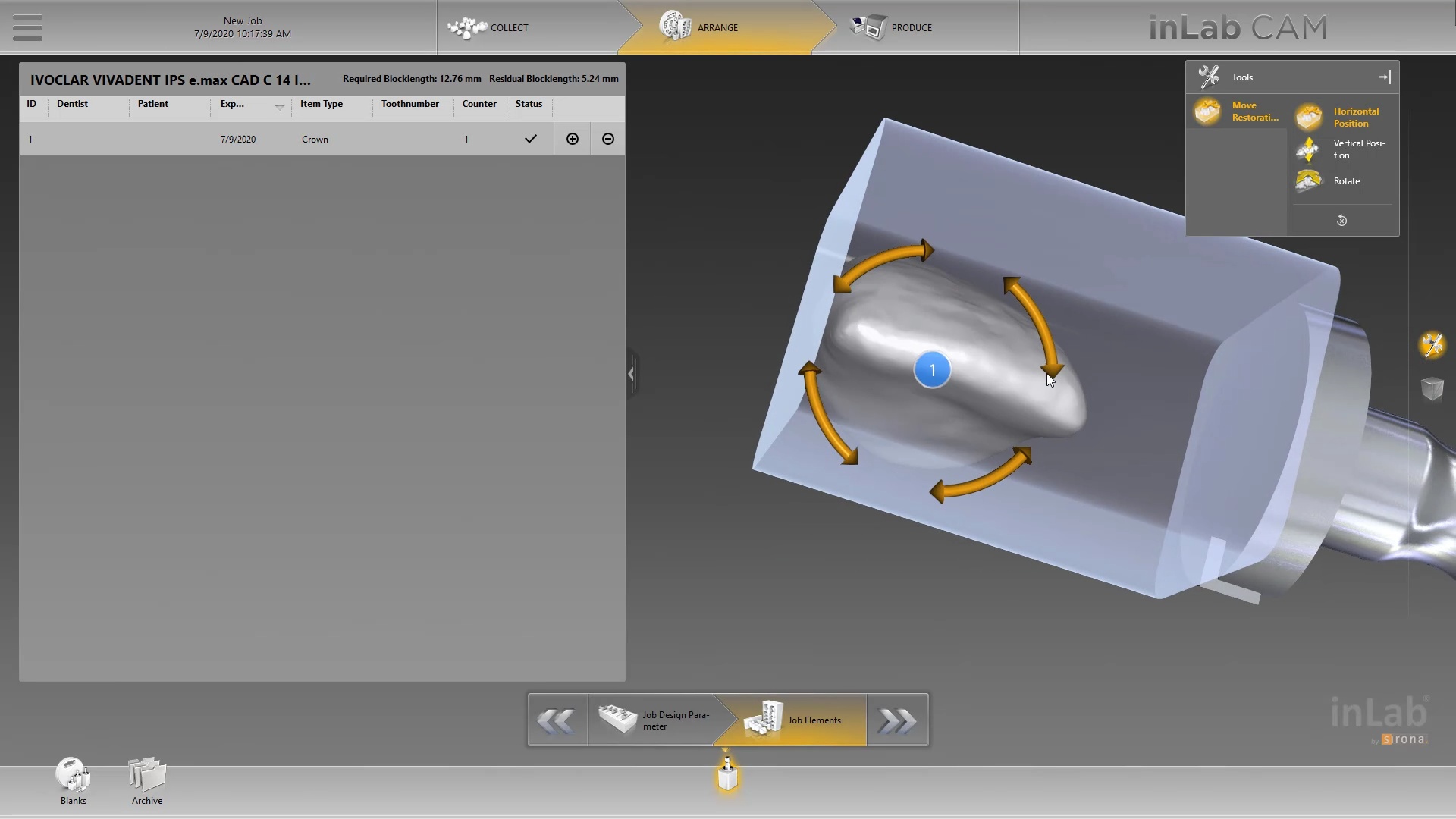

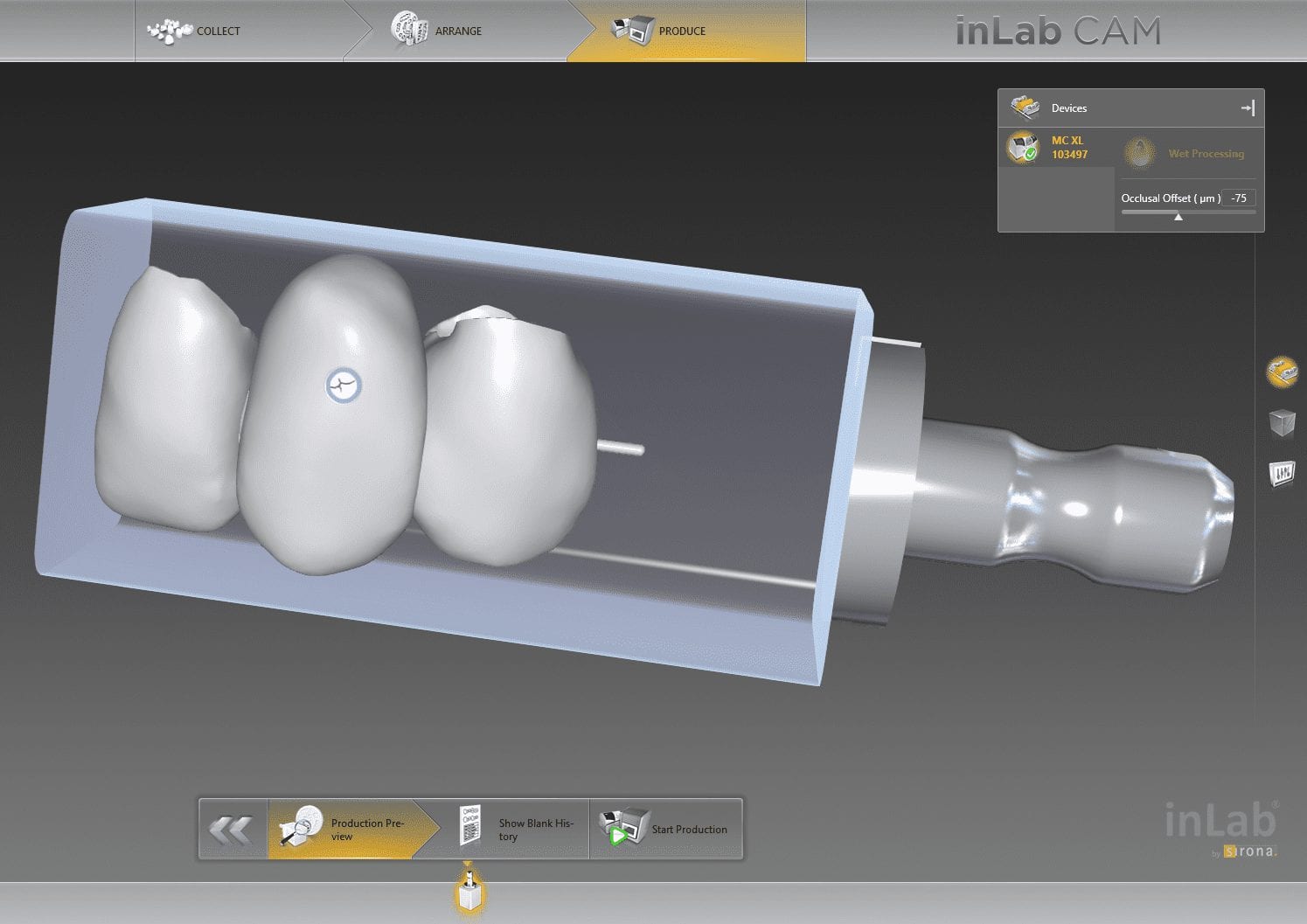

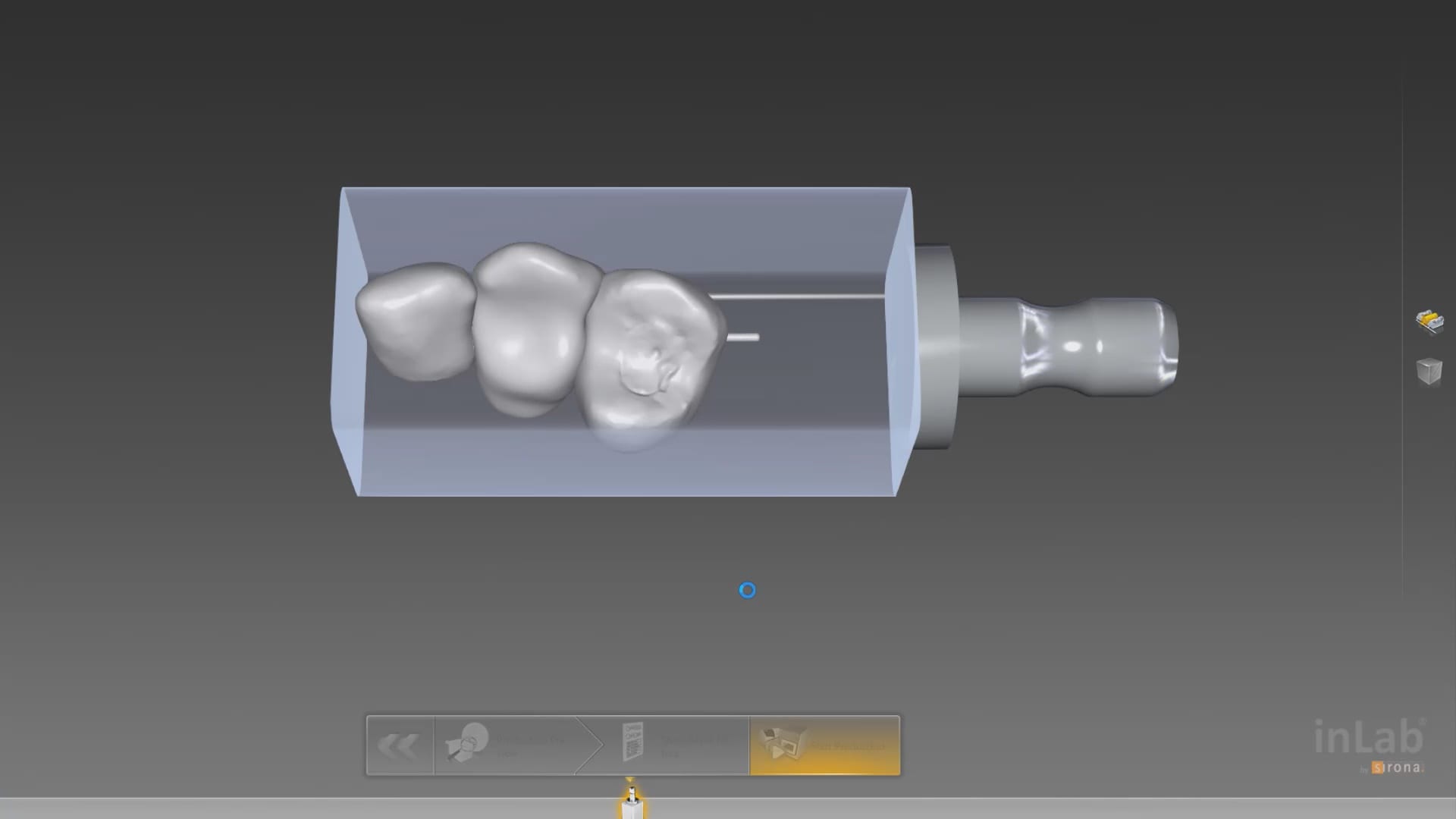

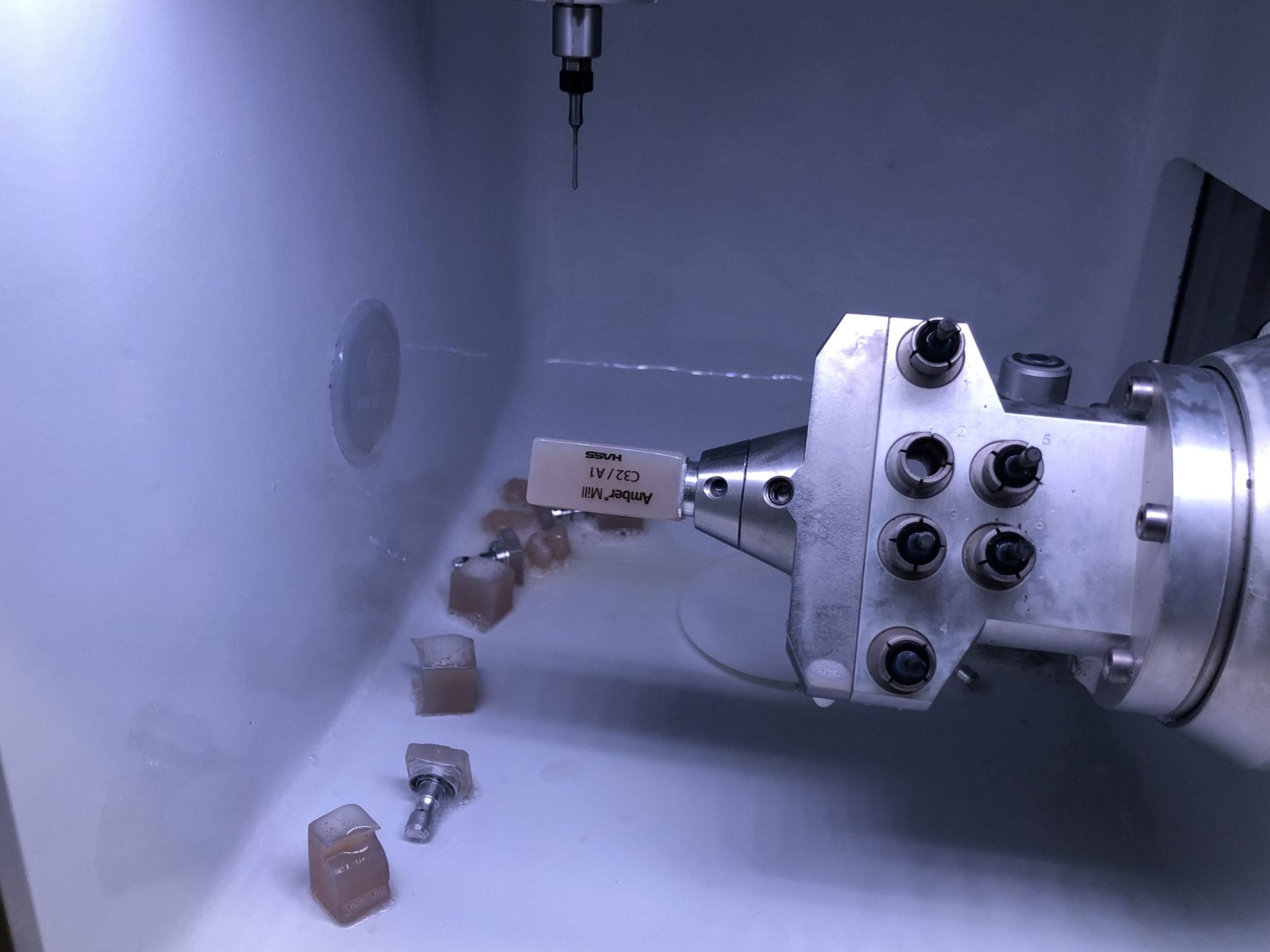

Once processed, you can then modify the tissue digitally and gain access to the tibase margins. You can print the model if you want and manufacture the restoration. In this particular case, we took the design to the CEREC mcxl inlab cam, nested it, and milled it out to demonstrate how we can image with one device from one manufacturer and fabricate a restoration by another company’s manufacturing machine. But the single greatest benefit is that you can place the sprue wherever you want.

IMPORTANT NOTE: The Tibase that you use MUST be wider than the drill milling the intaglio and the sprue must be thick enough to handle the milling process.

Once you understand how the digital workflow goes, you can image with one device, design in another, and then either print or manufacture with yet another device. Here we mill a sectional stent with the cerec that was designed in Blueskybio plan, although printing makes more sense because it is less wear and tear on your drills

PRODUCTS USED IN THIS CASE:

If you place enough implants, you may find yourself in need of a prosthetic part that just isn’t manufactured by anyone. For example, you may have a hybrid case on Bicons and for some reason you wanted to restored them with Multi Unit Abutments (MUA) and photogrammetry, yet there are no parts manufactured for such an endeavor. The problem is complex because a manufacturer needs to mass produce these parts and get them past regulatory matters.

Some have found a simple solution, which is to have the parts custom made specifically for the implant. If they need the MUA part before the procedure, they just send a digital or physical model into a lab that can custom make the part. The lab itself needs a prescription form on the lab analog. Since it is custom made, you have direct input on how tall you want the height of the margin, how much you want to displace the tissue, how much would want the restorative head angled, etc..

Some have found a simple solution, which is to have the parts custom made specifically for the implant. If they need the MUA part before the procedure, they just send a digital or physical model into a lab that can custom make the part. The lab itself needs a prescription form on the lab analog. Since it is custom made, you have direct input on how tall you want the height of the margin, how much you want to displace the tissue, how much would want the restorative head angled, etc..

Most people will order a variety of them to address any situation on the same model and keep it in stock. What’s important to realize is that from the restorative standpoint, all your CAD software needs to know is the location of your abutment margins. It doesn’t care where fixture is and how the timing is lined up in the arch form. As long as it knows where the margins are, you can proceed with the design of the prosthesis.

Contact Andrew Seddler to send a digital or physical model and an Rx to get your custom made MUA’s

A dentist from Australia named demonstrates in this video how you can scan with the Medit i500 and import the stl file into CEREC Inlab18, design a restoration, and fabricate a restoration.

This is a great option for CEREC users who want a second intraoral scanner or want to upgrade from bluecam to a color scanner, even though you can’t design in color

DISTINCT ADVANTAGES OF DIGITAL IMPRESSIONS

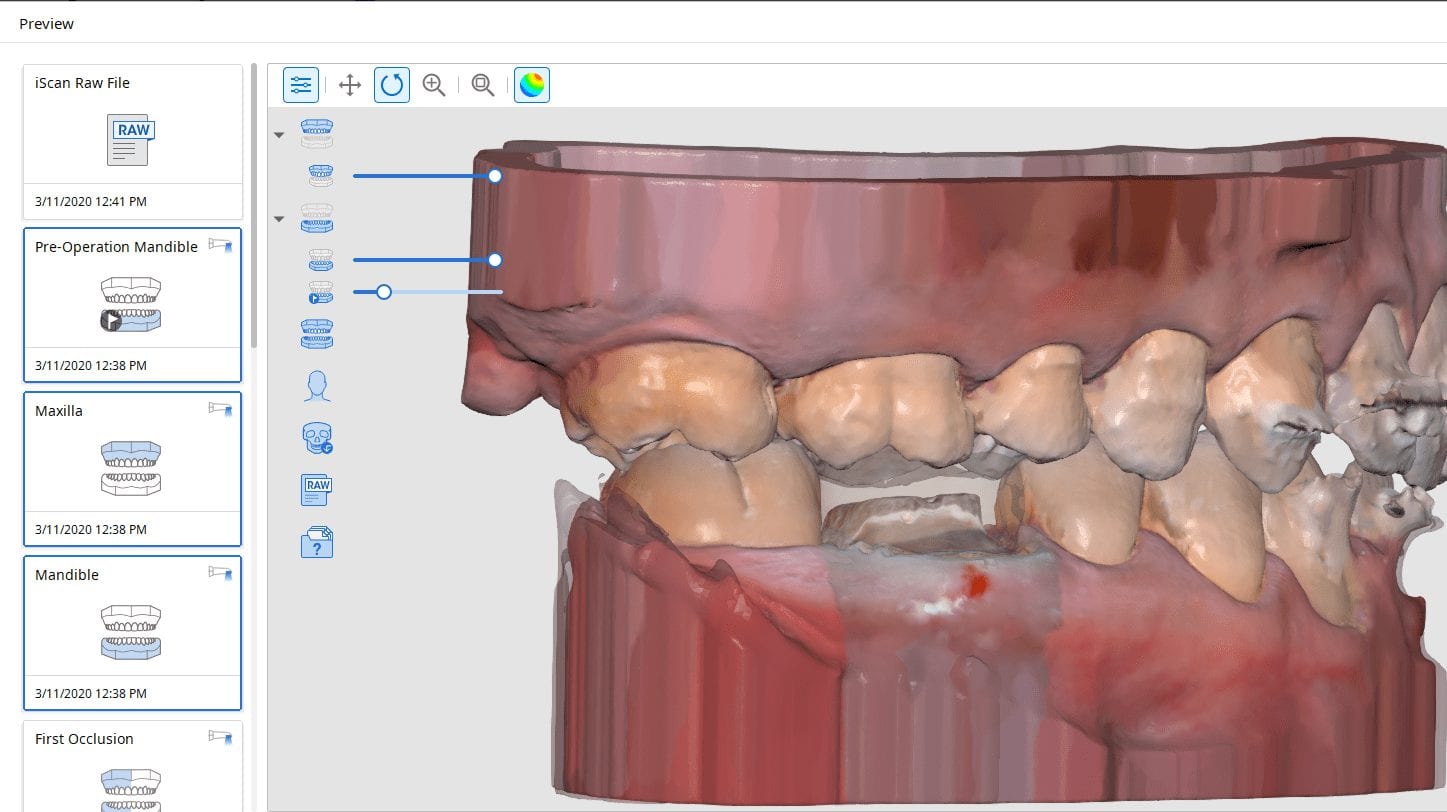

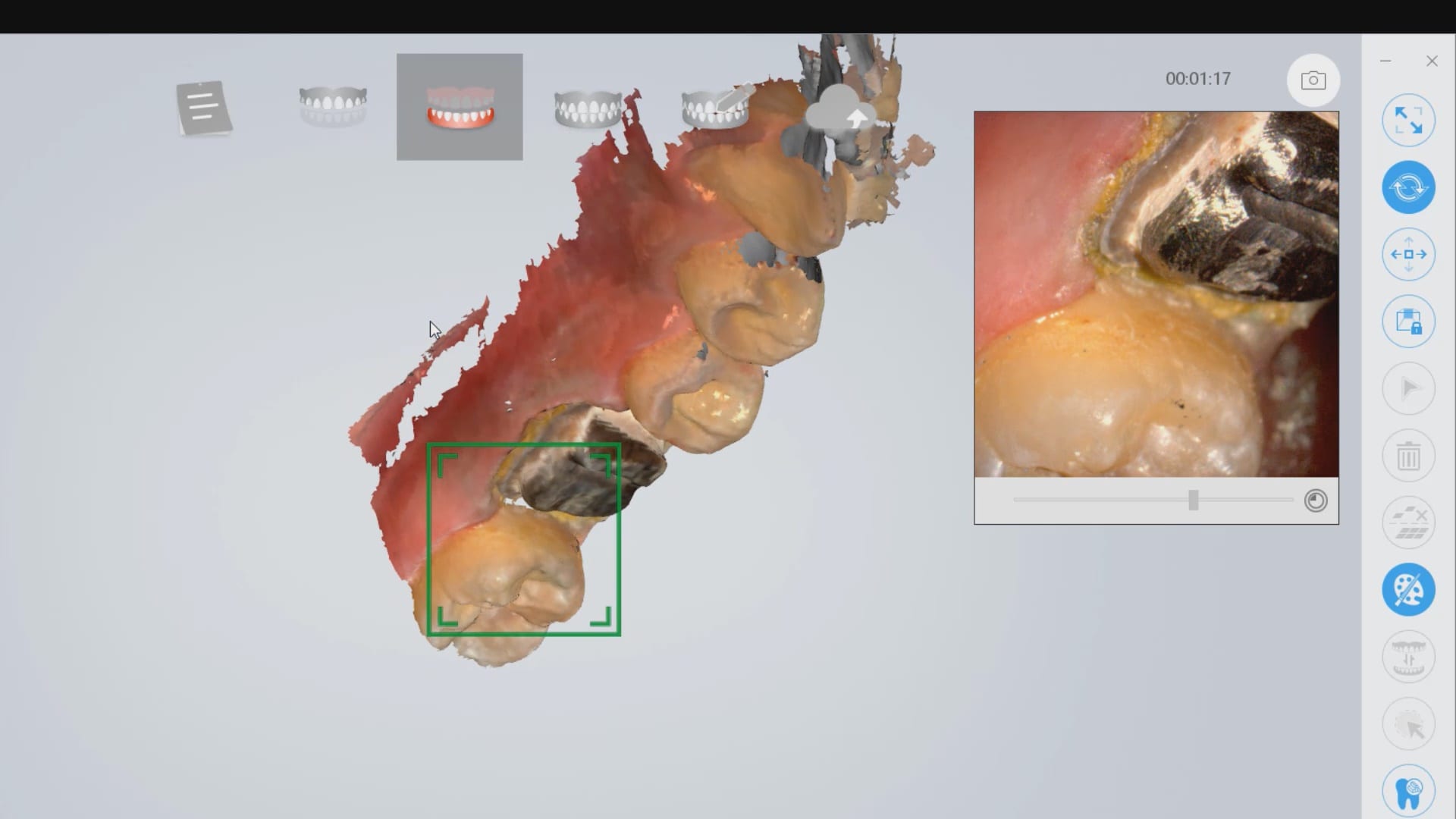

Here are two very simple examples of clinical advantages of digital impressions over analog ones. You can edit or add to your models and you can work independent of time and sequence.

You can also know immediately if you have captured your margins correctly. Once you understand these concepts, there are dozens of ways you can apply these principles to make some of the most challenging clinical cases very easy to manage

FIND OUT HOW RESTORING IMPLANTS CAN BE THE MOST PREDICTABLE PROCEDURE YOU CAN DO

For decades, placing and restoring implants was a very stressful and unpredictable procedure. Digital dentistry has reversed that trend, making it now the most predictable procedure you can perform. You can easily capture contacts, opposing dentition, and the location of the implant. More importantly, you can design the emergence profile to your liking.

SEE HOW EASY IT IS TO ADD A CONTACT TO A RESTORATION WITH AN OVEN

Emax restorations are milled in a pre-crystalized state (blue phase) as it is more gentle on the drills than the final crystallized form. A big advantage of emax lithium dissilicate material is that you can easily add contacts with addition powder in the same cycle as glazing. This reduces the stress of try-ins and allows you to recover without wasting precious time. Other materials on the other hand may require extensive oven times or a re-mill (or send the restoration back to the lab)

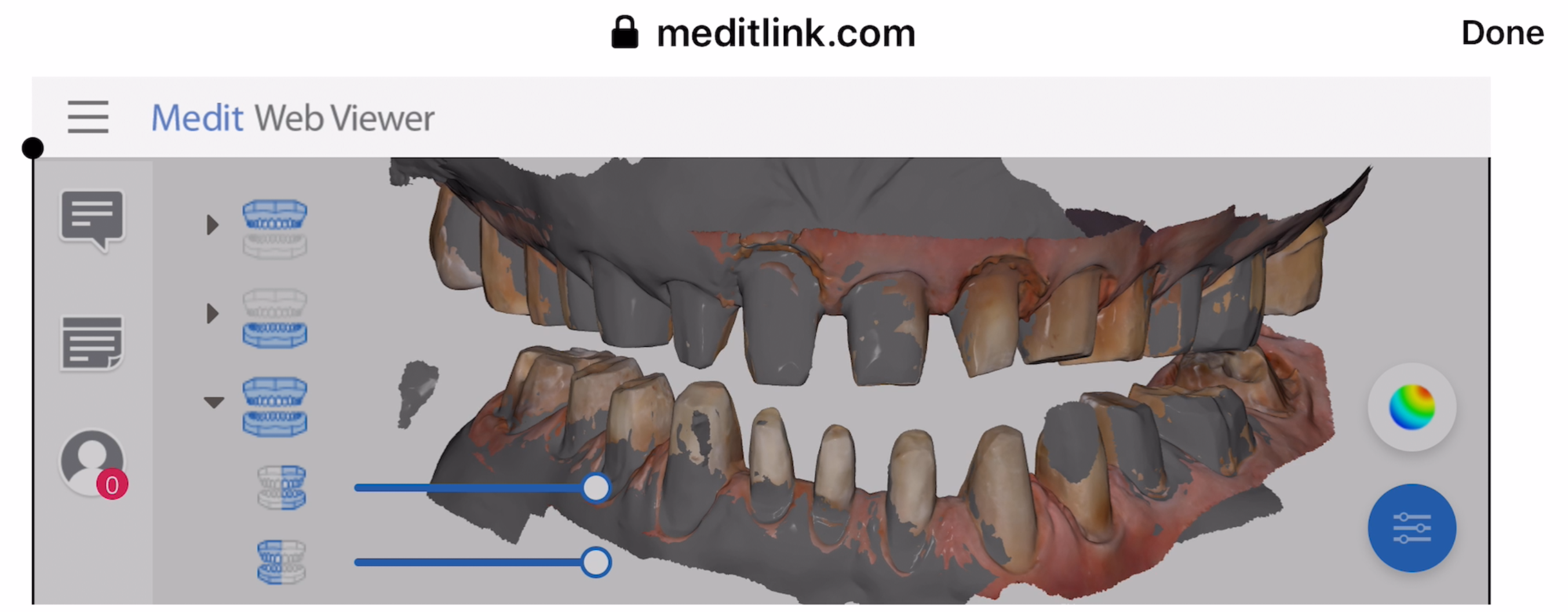

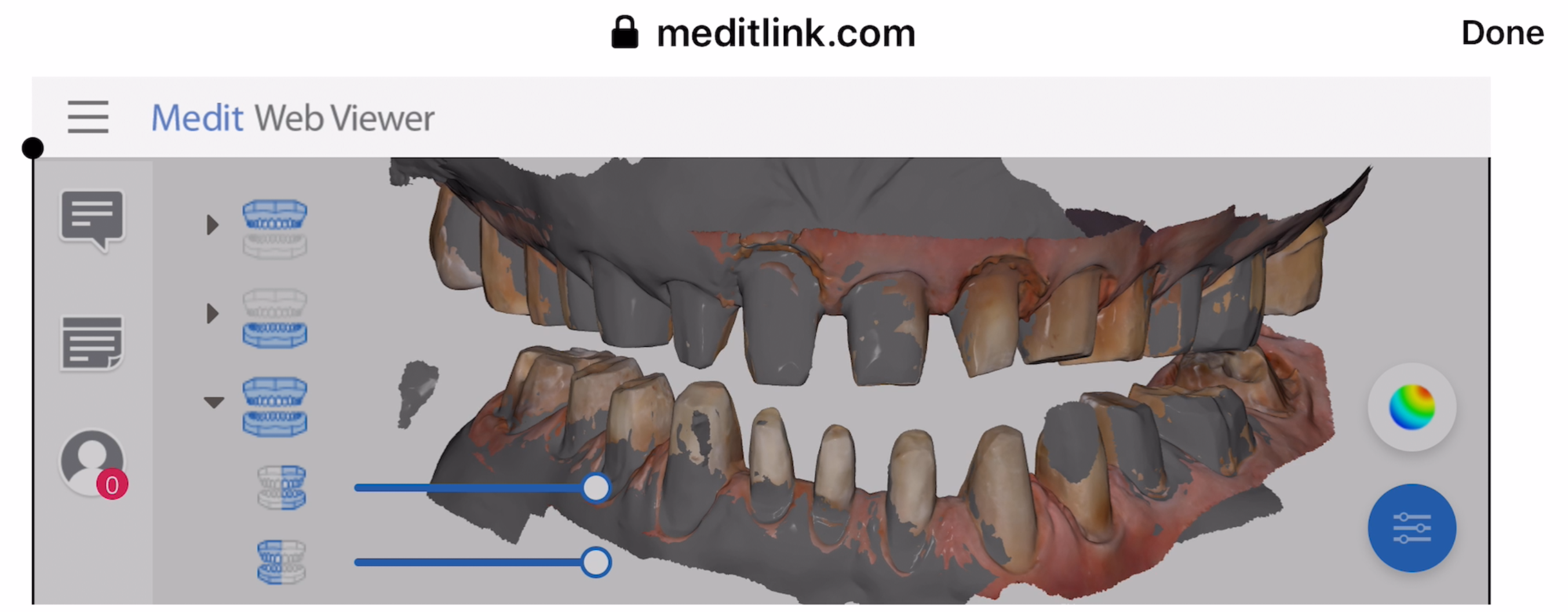

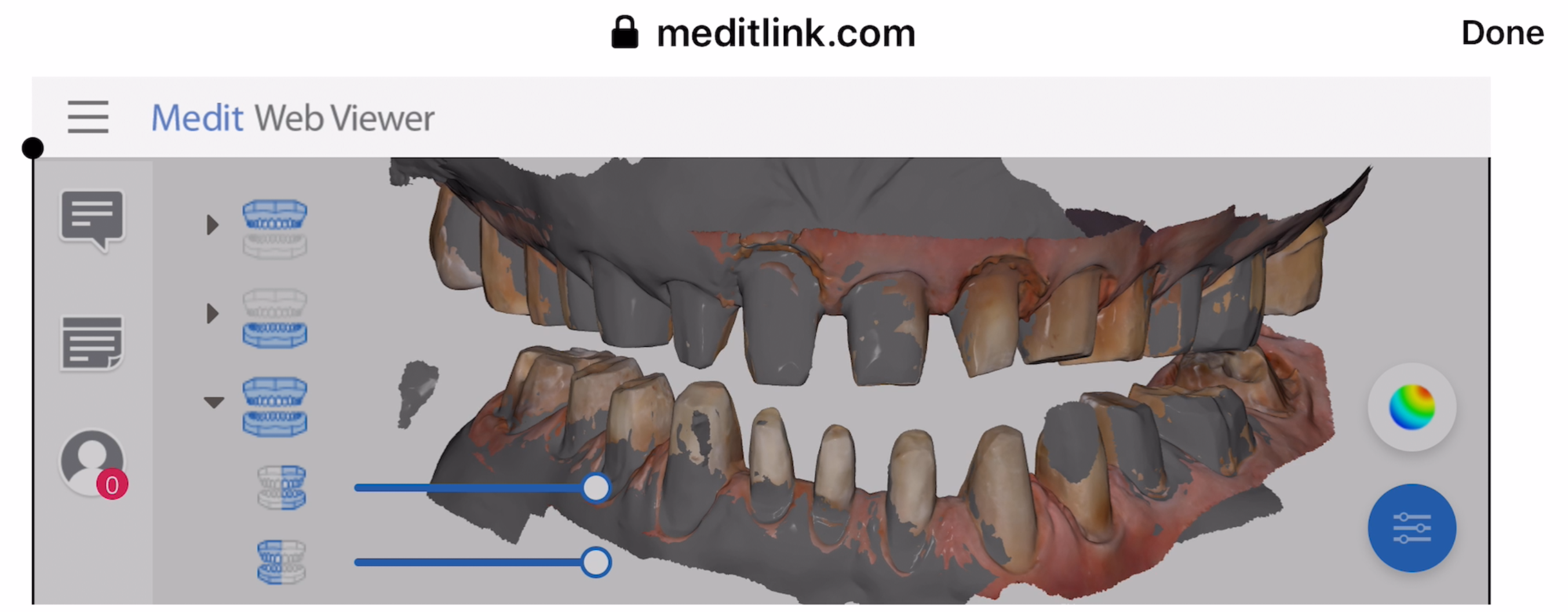

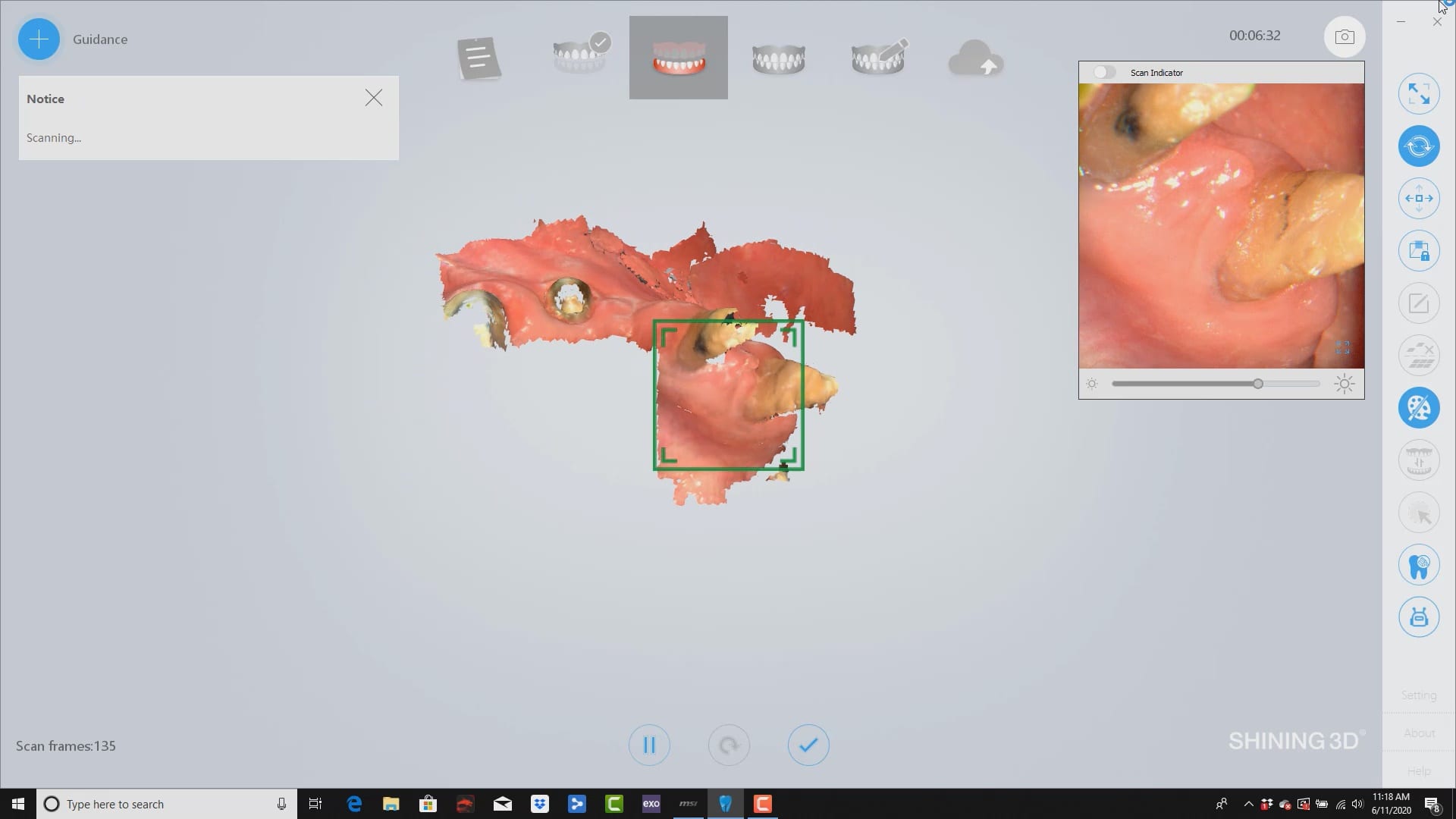

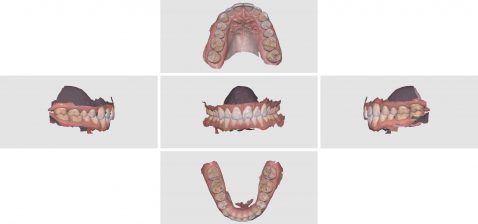

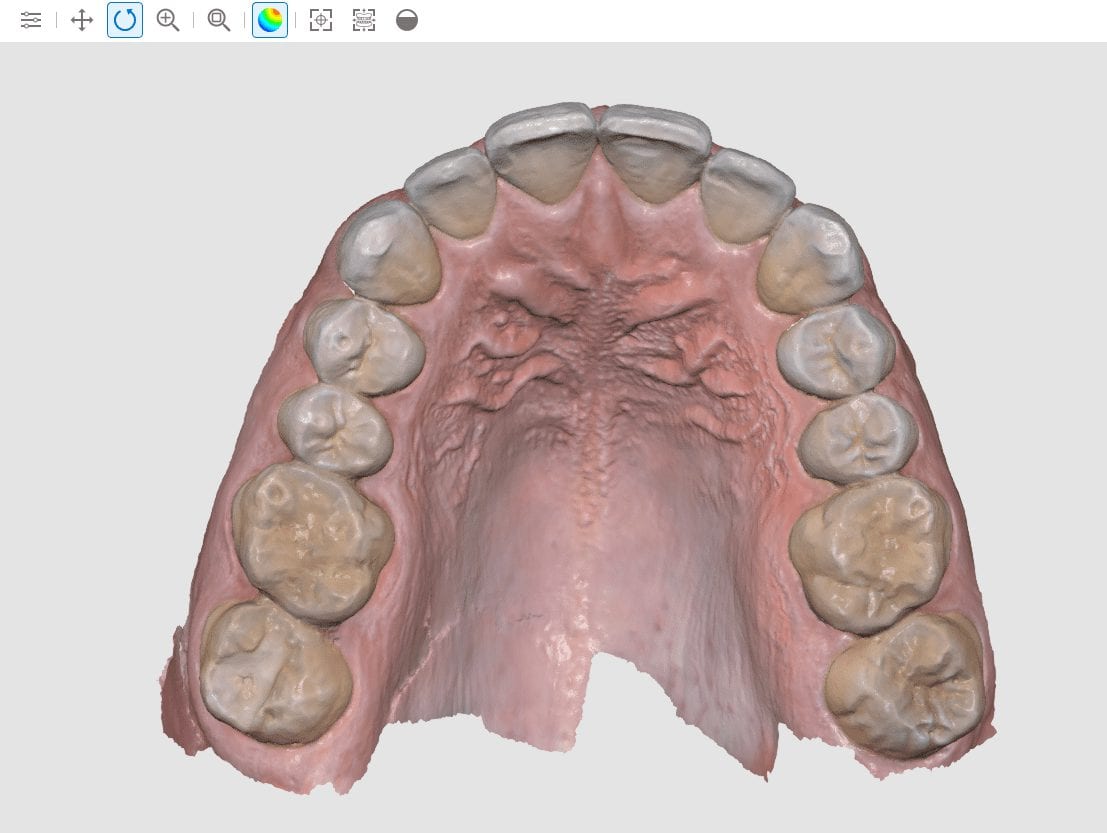

upper denture duplicated with shining 3d. only needed the occlusal and buccal surfaces as the case is for a lower overdenture over immediate extractions, on healed implants. went ahead and just duped the whole denture with the ios. very good results

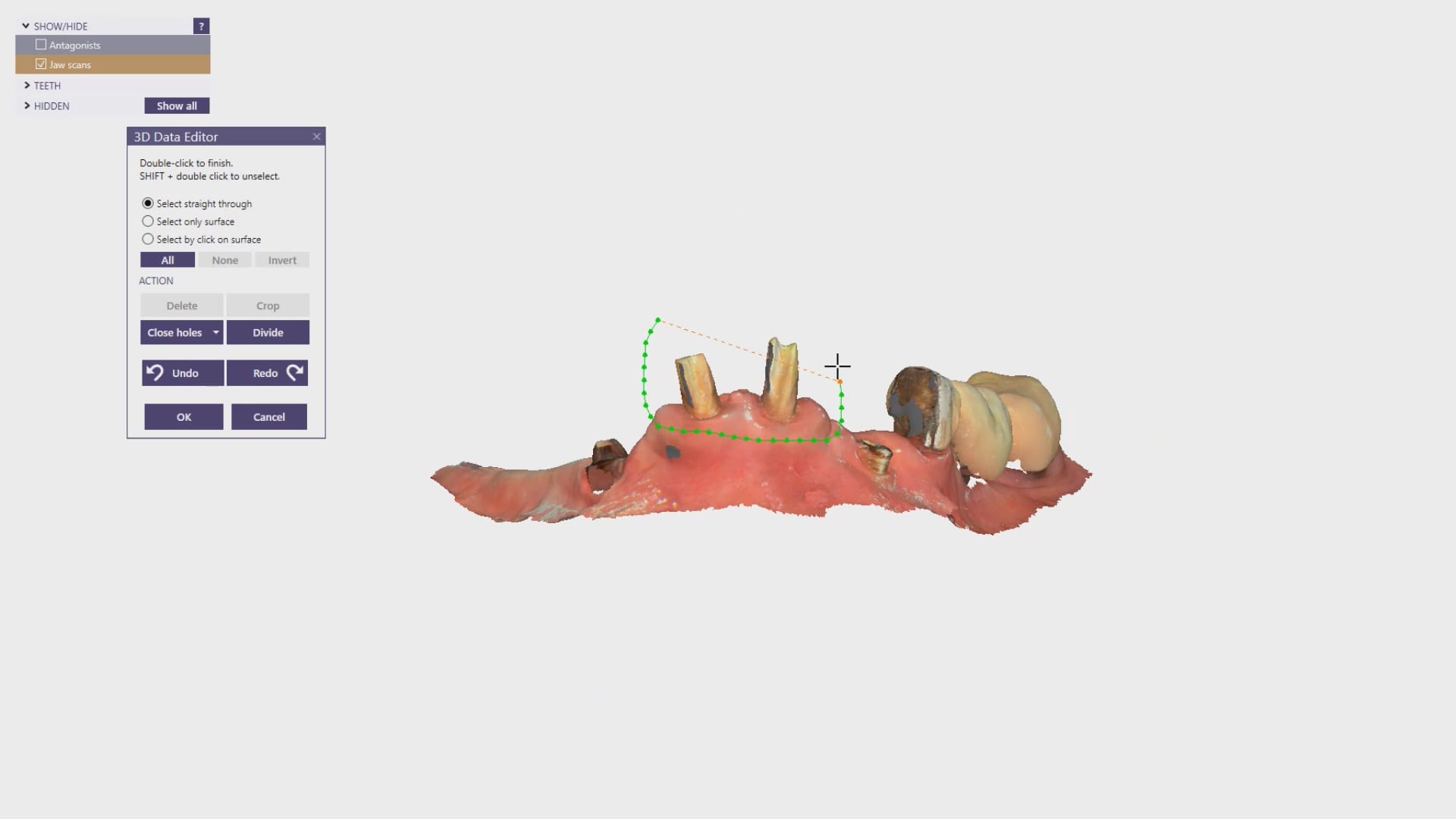

took off lower temps and scanned lower jaw. remaining teeth were used for long term temp abutments while implants healed. digital extractions performed and right vertical dimension for digital prosthesis design

Full arch imaging of mandible in preparation of overdenture

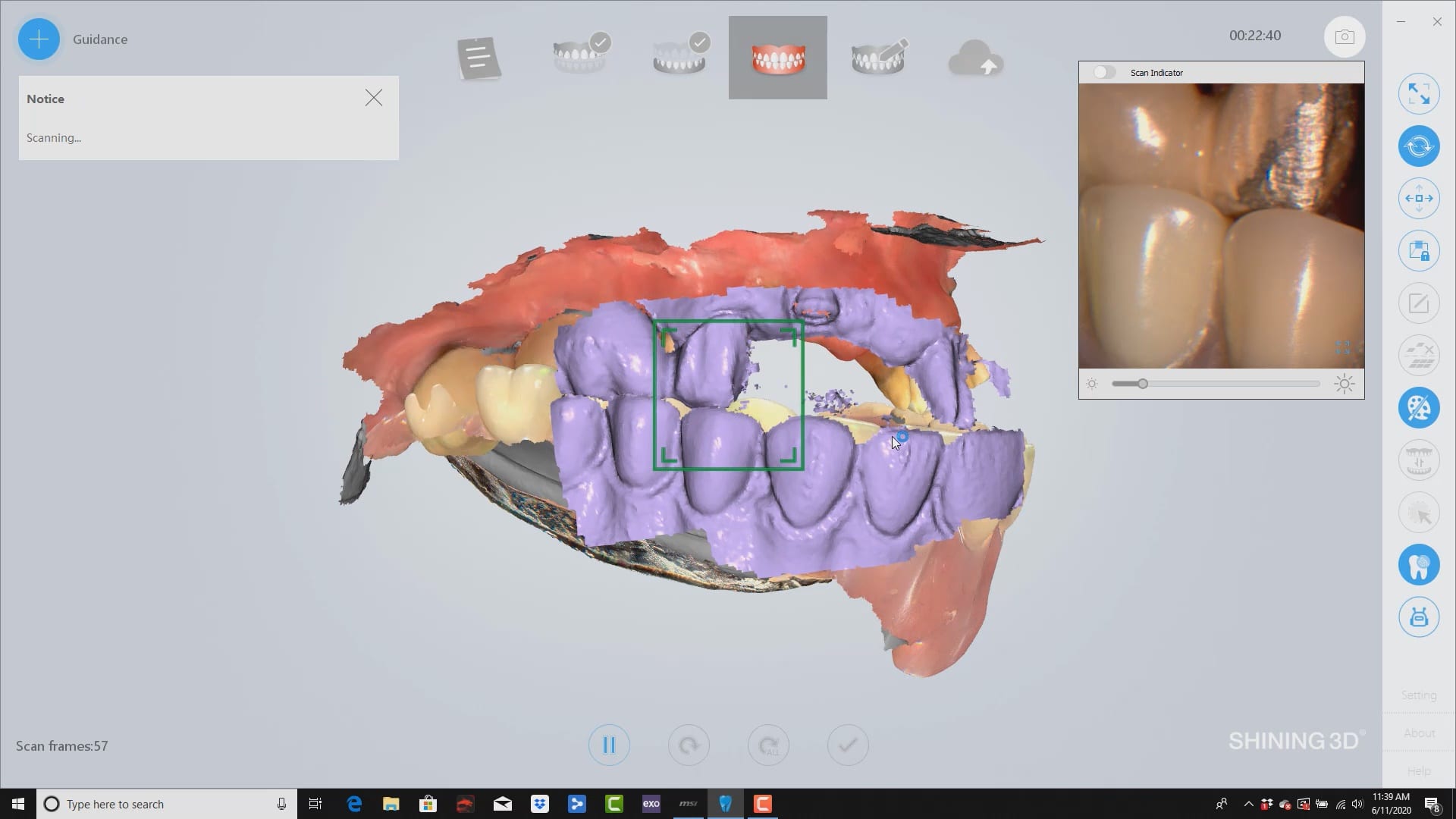

buccal bite taken intra-orally to mount arches at proper vertical dimension. you can see how the camera performs in this challenging case

Digital extractions performed in preparation for overdentures

Overdenture Design and Fabrication

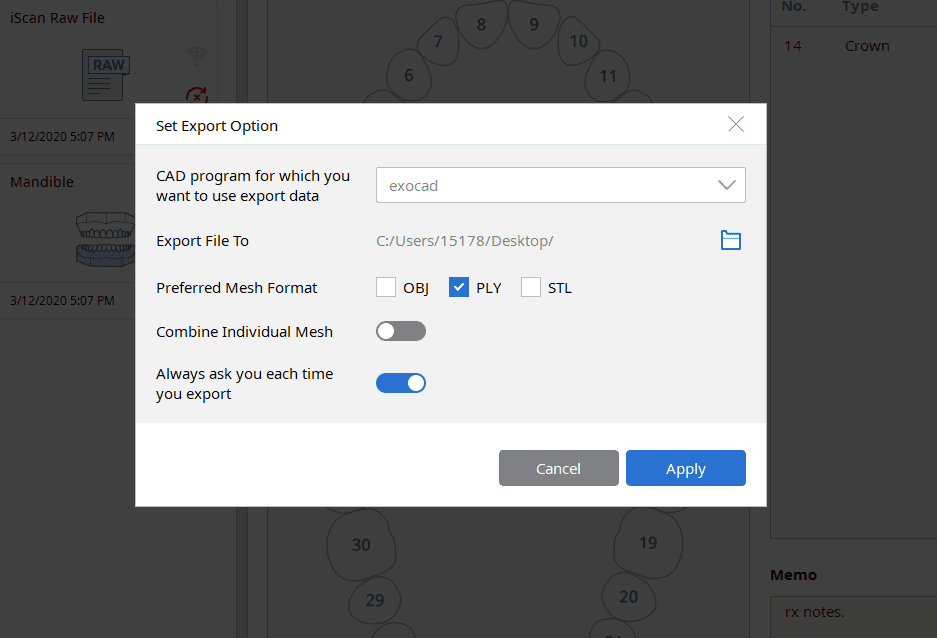

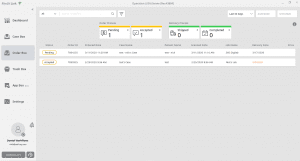

If you’re experienced with CAD/CAM technologies in dentistry, you probably already know how important file types and system integrations can be for the outcome of a project.

In this video, we briefly preview a workflow that is 100% digital and allows the user to freely select which products and programs they want to use within the phases of production.

Practicing with open system technologies puts the user in the driver seat allowing them to maintain control & freedom.

Furthermore, as time goes on these users can freely replace and upgrade components according to their treatment plans and the rate of innovation.

In conclusion, once doctors decide to upgrade their practice into digital workflows, they should invest in open system technology. When they make this decision they will experience several advantages such as cost savings, flexibility, more product options, and future proof set ups.

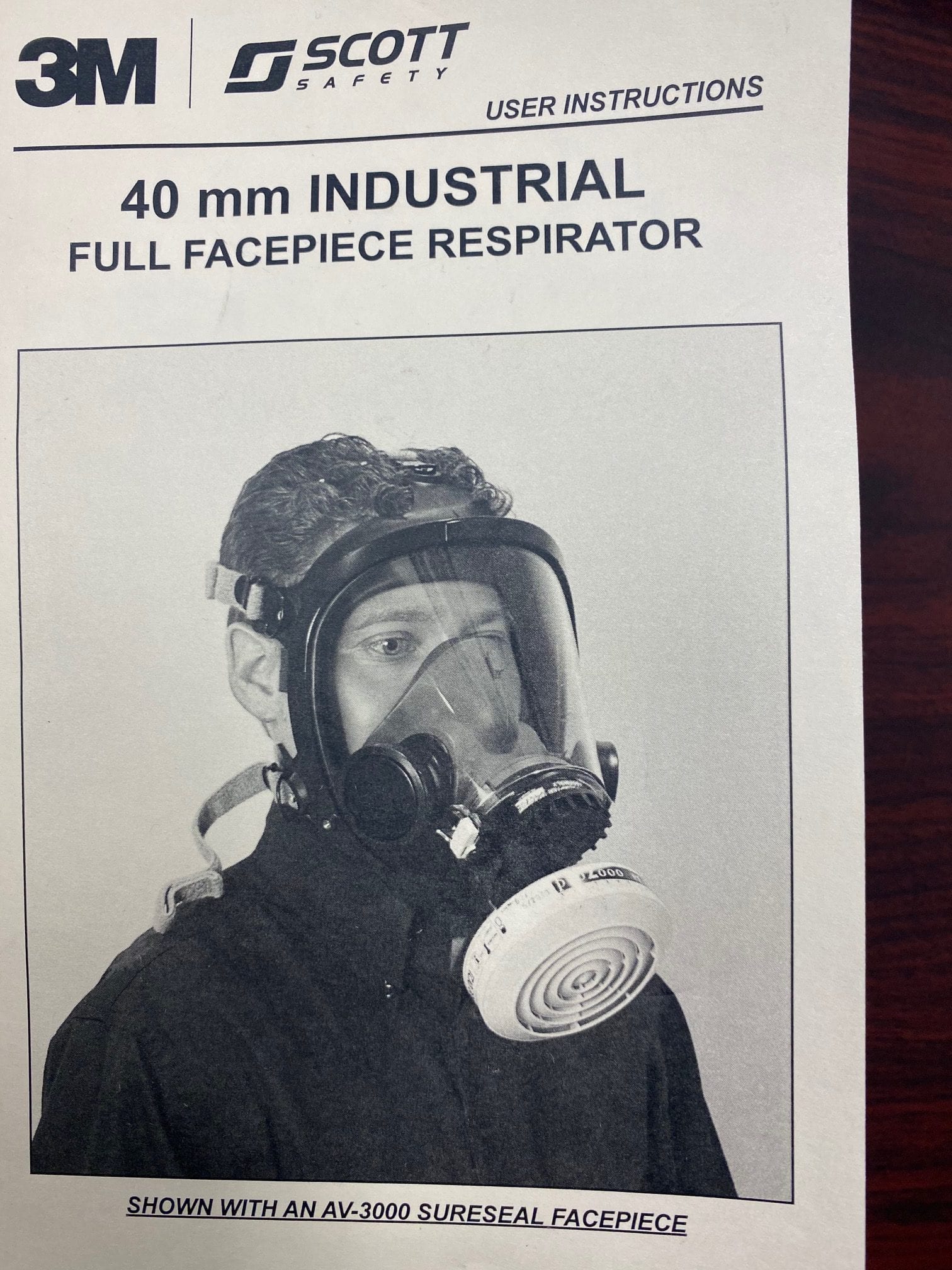

During these uncertain times with the COVID-19 virus, CAD-Ray has been on the front lines in the 3D printing and 3D design movement trying to help print masks and other goods for Healthcare workers on the front lines.

The other day, one of our CAD-Ray team members needed some help of his own

Story by CAD-Ray.com CTO, Jonathan Acker

It gives me great satisfaction to write this blog post. We are living in a strange time, and I’m glad to be able to share a positive story during this COVID-19 outbreak. This story bridges the gap between my worlds, and shows how the dental industry has A LOT to give during the fight against the virus.

Besides getting to work everyday at CAD-Ray with the most innovative team and customers in the dental profession; a life-long passion of mine has been serving my community in the role of firefighter/EMT at the Fallston Volunteer Fire and Ambulance Company in Harford County, Maryland. I’ve been riding ambulances and fire trucks since I was 16 years old – for the last 5 years at this department in the town where I reside. When I’m not working or home with my family, I can be found driving the ambulance, providing patient care as an EMT, or responding to the fire and rescue calls in our community. Holding the rank of captain, one of my roles is to ensure that all of our men and women in the Fire/EMS service have ample PPE to serve the public in a safe manner.

On Tuesday night March 24th at about 9 PM, the assistant chief of the department was inquiring if we knew anyone with access to a 3D Printer. I let him know that in my day job, I have access to many great dental labs who are experts at 3D printing. It turns out, this connection would allow us to solve a big problem.

In the midst of a massive PPE shortage because of the COVID-19 virus, equipment like N95 respirator masks are hard to come by, and are IMPERATIVE to keeping first responders like the members of my department safe as they interact on 911 calls with the public.

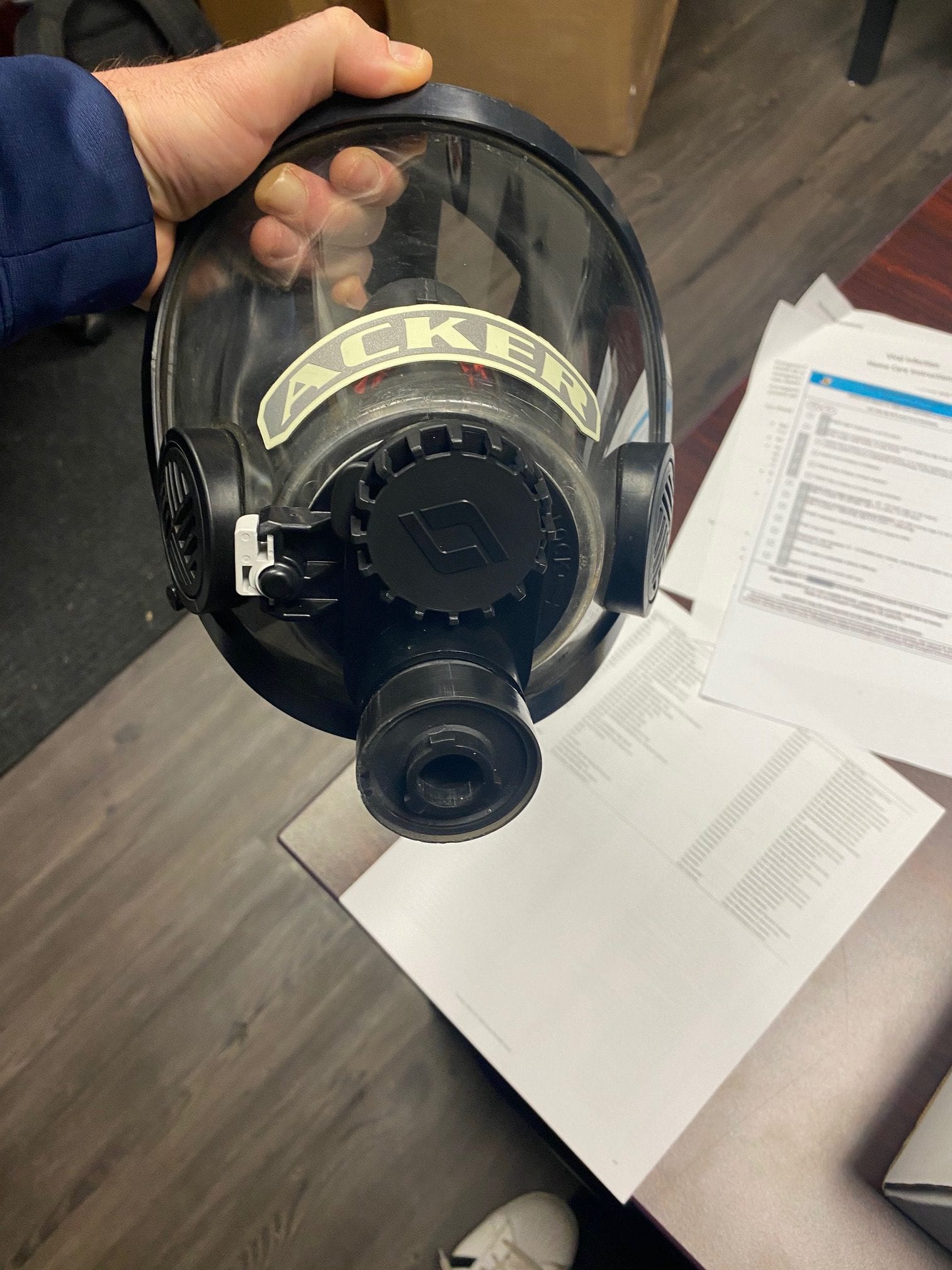

One potential solution to the lack of N95 masks is a filter fitting (that are readily available) that could snap into a firefighter’s own personally issued mask. This is the same mask that firefighters and medics would use to connect to their breathing apparatus regulator in the case of a fire. This seemed like a great solution for our department because it would adapt to our already existing equipment and avoid the use of disposables during this shortage – except there was one problem – there is a specific 40mm circular adapter that is required to fit the mask mounted housing for the filter to the filter itself – and due to the shortage of supplies – this small part as NOT AVAILABLE FOR 10 WEEKS.

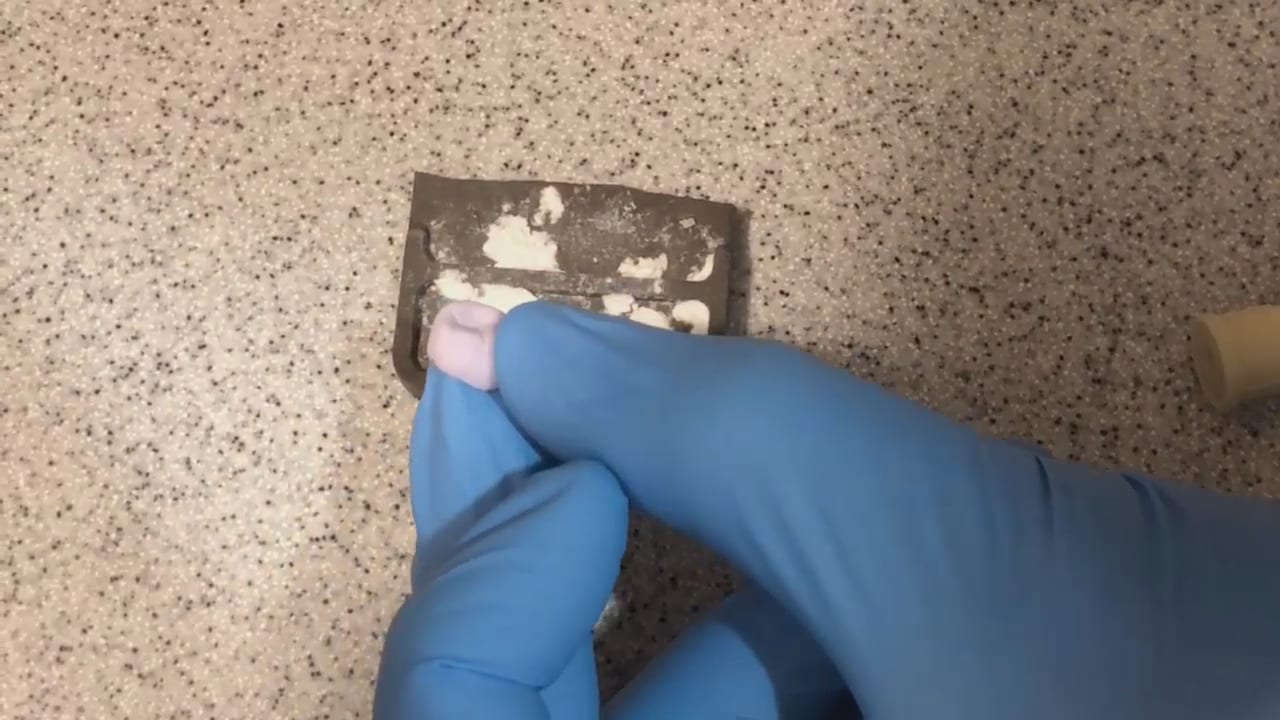

Luckily,we were able to get an OPEN .STL file of the part we needed. So at 9:30 PM, with the .stl file ready to share – I reached out to some friends in the dental lab business via text, email, and of course, facebook.

Within Minutes. Adam from Triple Crown Lab in Maryland, Rachel from Best Dental Studio in Maryland, Dr. Ho representing BARAN Dental Lab in Virginia, Colin from Red Mountain Dental Arts in Washington, and Rob from Patriot Dental Lab in Michigan all had responded saying they would be happy to help. I sent the file out and awaited some news.

By 11 PM Rob at Patriot Dental Lab had told me that one of his Technicians, Chad was already in the lab loading up resin, and getting the first 9 adapters printed. ( We need 20-40 for the department). By 2 PM the next day I had a message from Rob saying our first batch was printed, and on the way, and by 10 AM Thursday, we had our first set of adapters in hand, verified their fit and function, and issued to members of our department. An additional 18 are on the way from Rob as well as some others from the above mentioned labs.

Needless to say, I am so greatful to all of the lab owners who jumped in to help our department in our time of great need, especially Rob from Patriot Dental Lab who jumped out of bed, got to work and had these much needed parts in our hands in less than 30 hours, from 10 states away!

Dentistry, especially our great labs have so much to give during this time, and on behalf of CAD-Ray.com and the Fallston Volunteer Fire and Ambulance Company commend and thank all of you true Patriots who jumped in to help when we needed it most. It will never be forgotten!

When the time comes, please don’t forget to give Rob and all the labs above a shot next time you need some lab work done – they are In it for the RIGHT reasons. .

The Problem – Missing the needed adapter

For the last decade the rate of adoption and development in 3D scanning technologies has led to a tremendous amount of change in today’s dental workflows.

Smarter features, easier integration, new findings, and a worldwide understanding of 3D scanning is all leading to a better clinical outcome and an easier process for our patients and clinicians.

But if you’re a dentist or a specialist in 2020 looking for your first camera or even your next camera, pay close attention to this list of the top 12 qualities to evaluate. It could save you a lot of money and a lot of headache.

Here’s the list:

Support

Arguably the most important factor when considering a technology purchase. Do not take this lightly. Support is make or break.

First let’s define support. True support encompasses training, education, and help when you need it. Support is ultimately taking responsibility to help the end user maximize total value from the product to reach the desired end results.

Support should come from the product distributor so be sure to keep that in mind.

Is the team responsive when you need to contact them? Do they follow up? Do they have the knowledge to resolve technical issues? Are they clinically savvy with how you will be using the camera? What is their training platform? Do they offer continued education? Are they motivated to support you?

These are all important questions to consider first.

Software

Today software is the catalyst leading the way. It is the secret ingredient behind each intraoral scanner and is totally dependent on the engineering team behind the brand.

For intraoral scanners, software should be measured by the user interface, lab connection, third party software accessibility, and software upgrade consistency.

The best way to find this out is to check product websites for videos and descriptions. An even better way to check out the software is to contact the teams for short demonstrations to see it in action.

The software design is responsible for ease of use and will greatly influence the learning curve.

Versatility

What can the camera actually scan for? Is it single purpose or can you use it for multiple types of cases?

Some cameras are manufactured for specific indications while others are designed to image just about everything.

Be sure to dig into this. A great way to find out is through private, peer to peer doctor social media groups where you can post this question so all of the intraoral scanner users can respond with their feedback and experience.

Clinical Documentation

Ever purchase a product where they say it will do one thing but in reality it does another? Yeah, us too.

The distributor or manufacturer should reflect great effort in documenting the products they support in a clinical environment. Bonus points if you can find live footage for multiple cases like crowns, implants, partials, and full arch appliances.

It’s 2020, all cameras can image a stone model very well, that’s old news. But not all cameras can image a live patient as fast or as precise as their in vitro studies suggest they do. It’s important to find this out before you spend the capital.

Clinical documentation is the best way to find out if the camera is the real deal.

Cost

Bottom line price is always important.

We teach doctors to judge products on a price to performance ratio. Does the product value out weigh the price?

One of the main purposes of technology is to make money or to save money and it’s no different when you’re shopping for an intraoral scanner.

We recommend doctors consider cost in a 5 year time frame since you will most likely use the camera for at least 5 years before you replace or upgrade.

Compare the 5 year cost of the camera to your current chairside and labside expenses (do not forget to monetize chair time, retakes, and adjustments for a clear calculation).

Warranty

The industry standard includes a 1 year manufacturer warranty with technology purchases. This means should anything go defective with the product that can’t be solved remotely, the distributor and manufacturer will deploy a process to verify and then issue an RMA to repair or replace.

Key things to consider with warranties: Can you purchase an extended warranty? If so, do you have to purchase at the point of sale with the camera or is there a grace period to add it later? What does the warranty cover? Is the warranty process difficult and time consuming? Do they take the camera back for repair or do they send you a brand new unit? Do they have loaners available when your camera is down?

Be sure to collect all of this info.

Image Quality

Just like when you purchased digital x-rays or CBCT, image quality is everything. If you plan to send your 3D models to a lab this is probably the number one quality your designers care about.

Although scanning is entirely dependent on the user, the image resolution is derived from the projector, number of cameras within the scanner, and the software filters. Each of these play an important role in delivering the final model that is produced on your computer and used for final production.

Fortunately checking image quality is easy. You can usually find plenty of examples online or get digital models from the distributor.

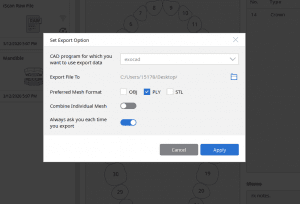

Open Source Files

Open system technology is a big discussion in the dental industry and it should be. There are many advantages to playing in the open source world.

STL, OBJ, and PLY files are what you want to look for. These are 3 universal files that can be freely exported and imported to and from the camera without fees or hassles. Ask your production partners what design software they use and what files they prefer to work with.

We recommend only considering open system technology so you can remain flexible both now and in the future. We see several doctors who spent serious money on closed system technology in the past to later find out when they want to add mills, cone beam, 3D printers, or other software that they cannot integrate and connect the pieces together. In the end this introduces a much heavier financial burden.

Be careful of this and you will save yourself a lot of headache.

Size

Fairly simple but do not forget. The size of the camera will greatly influence your user experience.

This is counter intuitive, but you will find that you do not want a camera that is extra small as you will never be able to learn how to use the camera hardware to block the patient’s cheek and tongue from the line of sight as you’re capturing images.

On the other end, purchase a large camera and you will leave your hands sore by the end of the day. We have found that large cameras have a difficult time imaging a full arch due to user fatigue. We have also found that large cameras have an incredibly difficult time reaching the second molar of the patient.

In the end, super small cameras are frustrating to the user while super large cameras are uncomfortable for the patient.

We suggest looking for a colleague nearby who practices with digital impressions so you can shadow a live patient case or test drive the camera in your own hands.

Modular Hardware

All intraoral scanners connect to a computer.

It’s important to stay modular and flexible with the exterior hardware so you can easily replace, repair, and troubleshoot when needed at a low cost.

We recommend staying away from proprietary computers because it can be harder to troubleshoot, run upgrades, download new drivers, or work through a warranty/repair process.

We have found the best ways to handle purchasing computer hardware for the intraoral scanner is to retrieve the manufacturer computer specs and shop for laptops or desktops depending on your setup.

Ongoing Fees

Monthly fees, annual fees, upgrade fees, export fees, subscriptions. Watch out for these.

They will add up especially when you go back to considering the 5 year cost of ownership calculation.

Today, the majority of digital dental manufacturers outsource new software development so as a result they have to pass on those expensive costs to their active users as an ongoing fee to fuel the R&D.

This is not the case with every distributor or manufacturer, but as you shop and research it is important to find out the ongoing costs as well as what happens if you do not pay the fees.

Our recommendation: if the camera has ongoing fees, run.

User Base

Finding a community of dentists and specialists who enjoy the product and consistently see results is good advice.

The user base should be responsive, helpful, and encouraging. Most groups create private discussion boards or pages on social media where they can freely post questions, new ideas, or clinical content. This can go a long way especially if you are new to the digital game.

Definitely run a quick search on facebook, youtube, and google to check into user groups across the web.

In conclusion, intraoral scanning technology is a game changer for the patients and the practice. The advantages are endless and once you start scanning you will never remember how you used to deal with messy impression materials or slow/expensive workflows.

But it’s important to shop smart and select the right camera for your expectations.

Follow the list of top 12 things to consider when purchasing dental intraoral scanners and you will thank yourself later.

If you enjoyed this article, please share it to help your peers or follow us on FaceBook at CAD-Ray.com.

In this video we demonstrate how the Aoralscan can complete a full arch scan utilizing the basic principles of digital impressioning.

Proper retraction, isolation, and scanning technique lead to high quality, error free models.

In Digital Dentistry, once you acquire your models accurately, the CAD software doesn’t care where and how you capture them. Once you are done with the design, the cam and the milling machine have no clue what scanner you used.

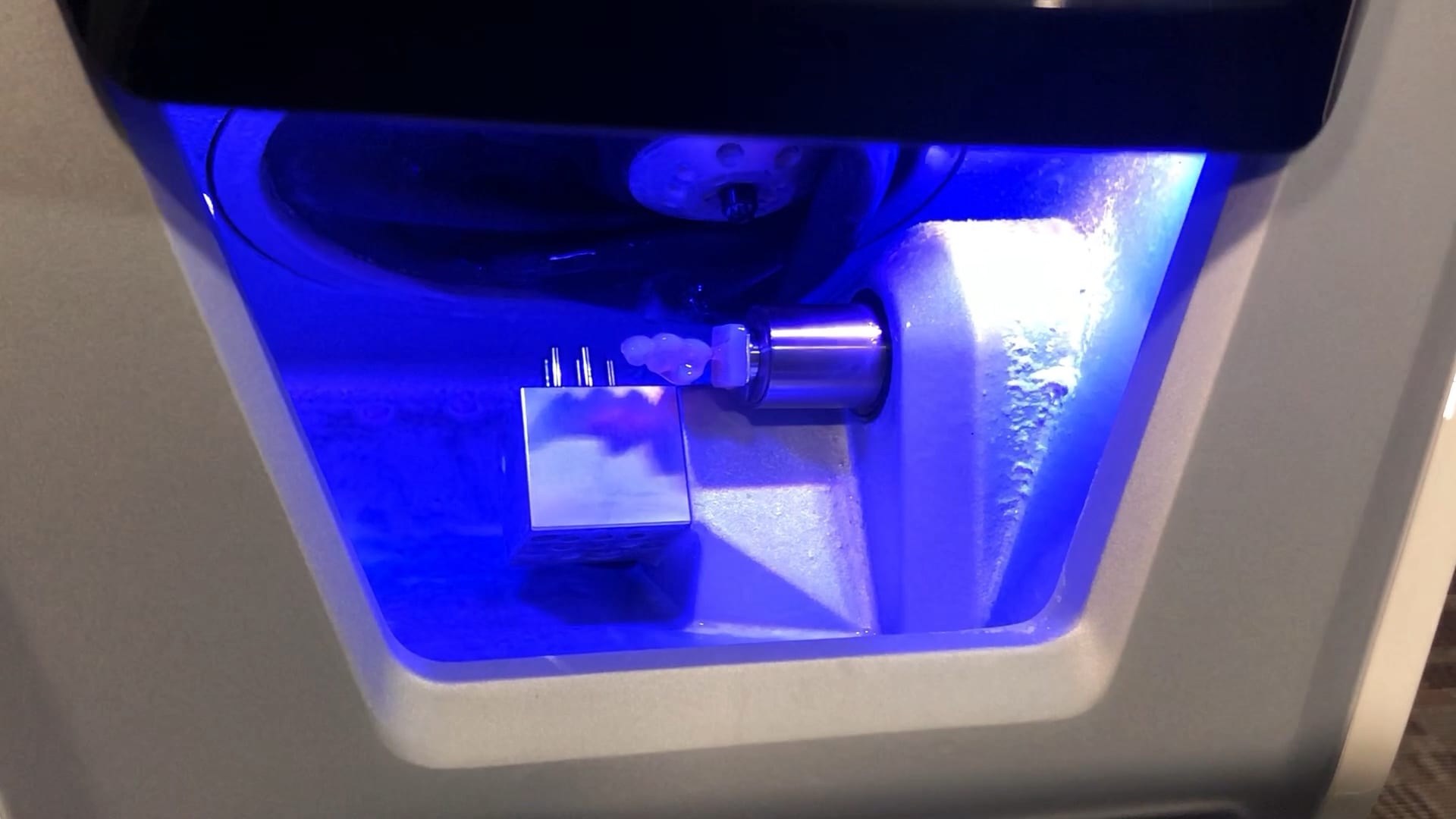

here we take an intra-oral scan with the medit i500 and design in exocad and send it to 2 different milling machines. One is the CEREC MCXL and the other is the imes icore coritec one.

we even milled the bridge with the z4 milling machine by vhf just to show the concept works

Please Note: This page is from dentalcadcamshop.com: 13.03.2020

When it comes to single visit dentistry (procedures in under 90 minutes), CEREC is tough to beat. From the integrated camera, CAD software and mill, CEREC is the most streamlined technology to serve patients in one visit.

Nevertheless, increasingly doctors are expanding their range of indications with CAD/CAM technologies and sometimes we simply want to combine CEREC with other equipment and software manufacturers. But wait, isn’t CEREC a closed system? Yes and no. While nobody would accuse CEREC of being a completely open system, it is possible to export .STL files of CEREC scans which gives us some flexibility to bring CEREC scans into other programs.

But today we are not focusing on exporting CEREC scans, but rather:

1) How can we bring scans from other cameras into CEREC?

Example: I own a 3rd Party Camera and I want to import those scans into CEREC for making crowns, etc.

2) How can we use CEREC to mill CAD objects made from 3rd Party Software?

Example: I own a 3rd Party CAD Software and want to import those into CEREC for milling.

But wait, I thought no 3rd Party files (scans or CAD designs) may be imported into CEREC. How, then, can we unlock the system? The missing piece to the puzzle is the inLab Software! With inLab Software, the CEREC system can be opened up for all kinds of interesting workflows. Here are two workflows CEREC owners constantly ask us about:

1) I own a 3rd Party Camera – How do I mill from my MC XL?

2) I own a 3rd Party CAD Software (e.g. exocad) and I want to mill (e.g. crowns) designed with 3rd Party software and mill them with my MC XL

Please note carefully the Requirements listed above!

– If you want to import a Scan .STL… You will need the inLab SW Interfaces Module, inLab CAD Software (18.0 and above) andthe inLab CAM Software (18.0 and above).

– If you want to import CAD .STL designs for milling… You only need inLab CAM Software (18.0 and above).

– In case you never owned any inLab Software before, or your copy of inLab Software is below 4.X, you will additionally need to order the License Stick (SKU: 6364785) and install the License Stick on the PC or workstation on which you are using the inLab Software (CAD or CAM). Please note this is NOT the same License Stick as you have on your CEREC AC unit!

– In no case can the inLab Software mill on the CEREC MC!

Still have questions? No problem, we are here with answers: Contact us

Good luck everyone and Happy Milling!

Import Scan .STL |

| P

V 18.0 Shop inLab SW Interface Module

|

P

V 19.0

|

Import CAD .STL |

| P

V 18.0

|

P

V 19.0

|

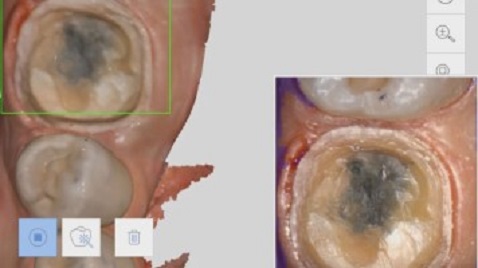

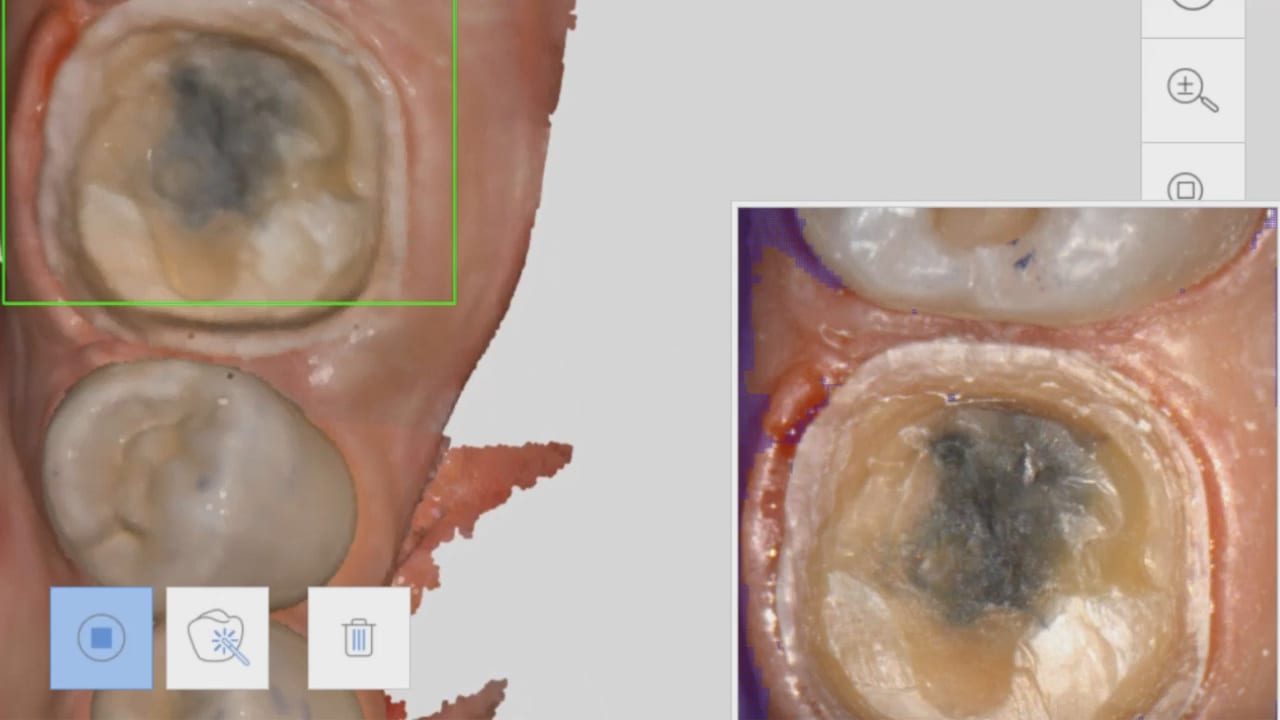

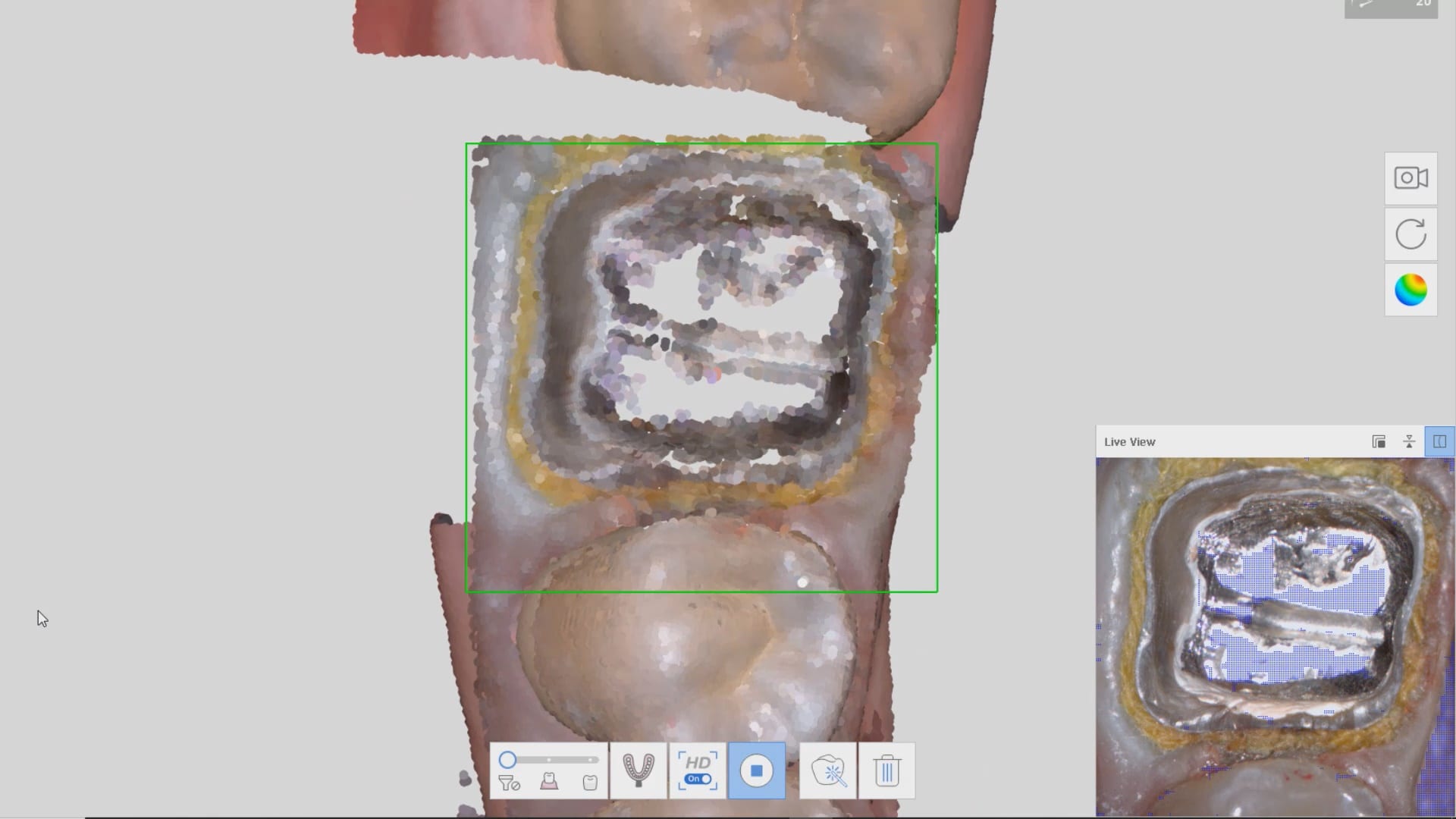

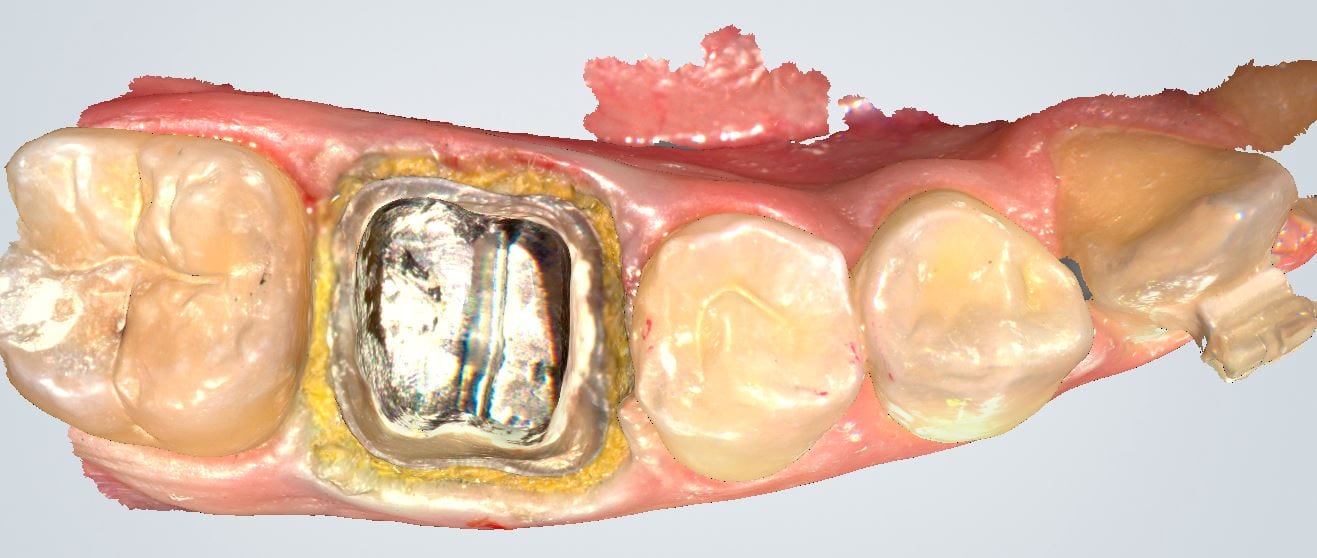

In this clinical video we demonstrate how to scan a molar preparation for the replacement of a crown with recurrent decay and open margins. The molar was root canal treated and the tissue was inflamed. the preparation was imaged and a temporary was fabricated to allow the tissue to heal properly.

The main point of this video is to show how to capture the contacts of the adjacent teeth and the deep marings

In this video we demonstrate how the Aoralscan from Shinning 3D captures deep margins.

An old PFM crown warranted replacement due to open margins and recurrent decay. After the crown was removed, the margins were refined and the tissue was displaced with expasyl and retraction cord.

This video is deliberately captured slowly so a new user can appreciate how to hold the camera to capture the margins and the contacts of the adjacent teeth. You also have the opportunity to place your own margins and the path of draw before submit the case to the lab.

You must be logged in to post a comment.